Building A Masonry Fireplace: A Comprehensive Guide

The construction of a masonry fireplace is a complex undertaking requiring careful planning, precise execution, and a thorough understanding of building codes and safety regulations. A masonry fireplace, traditionally constructed of brick, block, or stone, provides not only a visually appealing focal point for a room but also a source of supplemental heat. The process involves a multi-stage approach encompassing foundation preparation, structural construction, flue design, and aesthetic finishing. This article provides a detailed exploration of the process involved in building a masonry fireplace.

Planning and Preparation: Laying the Groundwork for Success

Prior to commencing any physical construction, meticulous planning is crucial. This phase involves several critical steps, starting with determining the fireplace’s location and size. The chosen location must consider structural integrity, ensuring the floor can bear the substantial weight of the fireplace. Examining existing floor joists and potentially reinforcing the floor may be necessary. Size is determined by the room dimensions, considering the fireplace's visual impact and heating capacity. A fireplace that is too large can overwhelm a small room, while one that is too small may be visually insignificant in a large space.

Next, acquiring the necessary building permits is a non-negotiable step. Building codes vary significantly by location, and failing to obtain the required permits can result in costly delays and potential legal ramifications. These permits ensure that the fireplace construction adheres to safety standards, particularly concerning fire resistance and chimney height regulations. Submitting detailed construction plans to the local building department is typically required to secure these permits.

Material selection is another vital component of the planning phase. The choice of brick, block, or stone will significantly impact the overall aesthetic and cost of the fireplace. Consider the desired style (traditional, contemporary, rustic) and select materials that complement the existing architectural design. Researching the thermal properties of different materials is also crucial, as this will affect the fireplace’s heating efficiency and performance. Quantity calculations must be precise to avoid material shortages or excessive waste. Add a buffer to the calculated amounts to account for potential breakage or cutting losses.

Finally, gathering all necessary tools and equipment is essential before starting any construction. This includes items such as a brick hammer, masonry saw, level, plumb bob, trowels of various sizes, mortar mixer (optional but highly recommended), safety glasses, work gloves, and scaffolding (depending on the fireplace height). Ensuring all tools are in good working order will contribute to a smoother and more efficient construction process.

Foundation Construction: Building a Solid Base

The fireplace foundation serves as the critical structural support for the entire assembly. Because of the considerable weight of a masonry fireplace, a properly built foundation is essential to prevent settling, cracking, and potential structural failure. The first step is excavating the soil to the depth specified in the approved building plans. This depth will vary depending on local frost lines and soil conditions. The excavation should extend beyond the footprint of the fireplace to allow for adequate footing support.

The next step involves pouring a concrete footing. This footing must be thick and reinforced with steel rebar. The rebar provides tensile strength to the concrete, preventing it from cracking under stress. The specific rebar size and spacing will be outlined in the building plans, but typically involves overlapping and tying the rebar together to form a grid. After pouring the concrete, it must be allowed to cure properly before proceeding to the next stage. Curing involves keeping the concrete moist for several days to allow it to achieve its full strength.

Once the footing has cured, the foundation walls can be constructed. These walls are typically built from concrete blocks or poured concrete. Block construction involves laying the blocks in a running bond pattern, ensuring that each block overlaps the block below it. Mortar is used to bind the blocks together, creating a solid and waterproof structure. For poured concrete walls, forms are constructed, and concrete is poured into the forms. Poured concrete offers a higher degree of strength and water resistance compared to block construction.

Regardless of the chosen method, ensuring that the foundation walls are level and plumb is critical. Any deviations from level or plumb can compromise the stability and appearance of the fireplace. A level and plumb bob are essential tools for maintaining accuracy during this stage. Waterproofing the exterior of the foundation walls is also crucial to protect the fireplace from moisture damage. Applying a waterproofing membrane or sealant to the exterior walls will prevent water from penetrating the foundation and causing issues such as efflorescence or structural weakening.

Firebox and Chimney Construction: The Heart and Soul of the Fireplace

The firebox is the core of the fireplace where the fire actually burns. Its construction requires particular attention to detail and adherence to safety regulations. It must be built from fire-resistant materials such as firebrick, which is specifically designed to withstand high temperatures. The firebox dimensions are crucial and should be determined based on the desired fire size and the overall design of the fireplace. A firebox that is too small will not generate sufficient heat, while one that is too large can be inefficient and potentially dangerous.

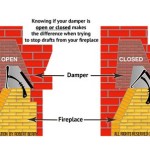

The firebrick is typically laid using a refractory mortar, which is formulated to withstand high temperatures and resist cracking. The joints between the firebricks should be as thin as possible to minimize heat loss and prevent smoke leakage. The firebox walls should be slightly angled inward to help reflect heat into the room and improve combustion efficiency. A smoke shelf is typically incorporated into the design just above the firebox. This shelf helps to prevent downdrafts from entering the fireplace and interfering with the draft.

Above the firebox is the smoke chamber, which funnels smoke up into the chimney. The smoke chamber should be smoothly tapered to optimize airflow and minimize turbulence. The walls of the smoke chamber are typically parged with a smooth layer of refractory mortar to further improve airflow and prevent smoke leakage. The chimney is the vertical structure that carries the smoke and combustion gases away from the fireplace. It must be tall enough to create sufficient draft to draw air into the firebox and expel the smoke effectively.

The chimney is typically constructed from brick, block, or stone, and must be lined with a flue liner. The flue liner is a ceramic or metal pipe that provides a smooth and fire-resistant pathway for the smoke. The flue liner size must be carefully calculated based on the firebox opening area. A properly sized flue liner ensures adequate draft and prevents the buildup of creosote, a highly flammable substance that can lead to chimney fires. The chimney must extend at least three feet above the highest point of the roof and at least two feet higher than any part of the building within ten feet. This ensures adequate draft and prevents smoke from blowing back into the building.

As the chimney rises, it is important to install flashing around the chimney where it penetrates the roof. Flashing is a metal barrier that prevents water from leaking into the building around the chimney. The flashing must be carefully installed and sealed to ensure that it is watertight. A chimney cap is typically installed on top of the chimney to prevent rain, snow, and debris from entering the flue. The chimney cap also helps to improve draft and prevent downdrafts.

Aesthetics and Finishing: Adding the Final Touches

Once the structural elements of the fireplace are complete, the process of adding aesthetic finishes begins. This stage allows for customization and the incorporation of design elements that complement the surrounding décor. Applying a facing material to the exterior of the fireplace, such as brick, stone, or tile, can dramatically alter its appearance. The facing material should be carefully selected to match the desired aesthetic and coordinate with the existing architectural style of the room.

Mortar joints can be finished in a variety of ways, including flush, raked, or tooled. The choice of mortar joint finish will affect the overall texture and appearance of the fireplace. A flush joint creates a smooth, seamless look, while a raked joint adds depth and shadow. A tooled joint can create a more refined and decorative appearance.

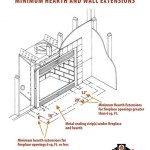

The hearth, which is the area in front of the firebox, provides a safety barrier and adds visual appeal. The hearth should be constructed from non-combustible materials such as brick, stone, or tile. The hearth should extend at least 16 inches in front of the firebox opening and at least eight inches to either side. This provides adequate protection from sparks and embers that may escape from the firebox.

Installing a mantel adds a focal point to the fireplace and provides a space for displaying decorative items. The mantel can be made from wood, stone, or other materials. The mantel must be installed at a safe distance above the firebox opening to prevent it from catching fire. Building codes typically specify minimum clearances between the mantel and the firebox opening. Other decorative elements, such as fire screens, tool sets, and andirons, can be added to enhance the fireplace’s aesthetic appeal and functionality.

How To Build An Indoor Fireplace The Constructor

Ahren Fire Fireplace Systems An Answer To Improper Construction Chimney Savers

Building A Fireplace Fine Homebuilding

How To Build An Indoor Fireplace The Constructor

Concrete Masonry Fireplaces Entire Tek

Masonry Fireplaces Cottonwood Modern Life Of An Architect

Fireplace Installation Memphis Tn Coopertown Services

Fireplaces A Construction Primer Masonry Fireplace Chimney Design Dimensions

Masonry Stoves Heaters And Fireplaces Build Your Own

Masonry Fireplace Dvd Build A Stove Russian Or Heater

Related Posts