Building a Frame for a Gas Fireplace Insert

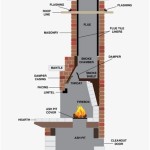

A gas fireplace insert provides an efficient and aesthetically pleasing way to upgrade an existing fireplace. A crucial part of this upgrade involves building a frame to house the insert securely and ensure proper clearances for safety. This article details the process of constructing such a frame, outlining the necessary materials, tools, and steps involved.

Before embarking on the project, consult the manufacturer's instructions for the specific gas fireplace insert being installed. These instructions will outline the required clearances for combustible materials, which are critical for fire safety. Local building codes also govern fireplace installations, and obtaining necessary permits and inspections is essential.

Accurate measurements are the foundation of a successful framing project. Begin by measuring the fireplace opening, noting the height, width, and depth. The frame dimensions will be based on these measurements, taking into account the manufacturer's specified clearances. It is generally recommended to build the frame slightly smaller than the fireplace opening to allow for adjustments and ensure a snug fit.

The framing material typically used is kiln-dried lumber, often 2x4s or 2x6s, chosen based on the size and weight of the insert and the specific requirements outlined in the manufacturer's instructions. Pressure-treated lumber is not recommended for interior fireplace framing due to the chemicals used in the treatment process.

Essential tools for this project include a measuring tape, safety glasses, a carpenter's square, a level, a circular saw or miter saw, a drill with appropriate drill bits, a reciprocating saw (if modifications to the existing fireplace are necessary), screws, and construction adhesive. Having the right tools readily available streamlines the process and ensures accuracy.

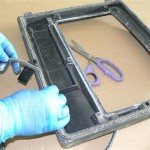

The frame construction begins by cutting the lumber to the calculated dimensions. Employing a miter saw or circular saw ensures clean, accurate cuts. The pieces are then assembled using screws and construction adhesive, forming a rectangular frame. It's vital to use a carpenter's square to ensure accurate 90-degree angles at the corners for a stable and square frame.

Once the basic frame is assembled, it's necessary to check its dimensions against the fireplace opening. Minor adjustments can be made at this stage. The frame should fit snugly but not be forced into the opening. If the existing fireplace opening requires modifications, such as enlarging it slightly, a reciprocating saw can be used, taking care to protect surrounding surfaces.

Securing the frame to the existing fireplace structure is the next step. This can be achieved using screws, metal brackets, or a combination of both. The specific method will depend on the construction of the fireplace and the surrounding materials. Ensuring a solid, secure attachment is critical for the stability and safety of the installation.

The framing process may necessitate creating a support platform for the insert, particularly if the insert requires elevation. This platform can be constructed from the same framing lumber, ensuring it is level and capable of supporting the weight of the insert. Consult the manufacturer's instructions for the required platform dimensions and load-bearing capacity.

Insulation may be required around the frame, depending on the manufacturer's instructions and local building codes. This insulation helps to protect surrounding combustible materials from the heat generated by the insert. Fire-resistant insulation materials, such as mineral wool or ceramic fiber insulation, should be used for this purpose.

After the frame is secured and insulated, it's important to check the clearances around the frame once more. These clearances should match the manufacturer's specifications to ensure safe operation. Any gaps or irregularities can be addressed using non-combustible fillers, such as mineral wool or ceramic fiber board.

Finishing the frame is typically done with non-combustible materials. Options include cement board, sheet metal, or a combination of both. These materials provide a fire-resistant surface and can be finished to match the surrounding décor. Detailed finishing instructions will vary based on the chosen material and the desired aesthetic.

Throughout the entire process, prioritize safety. Wear appropriate safety gear, including safety glasses and dust masks, and ensure adequate ventilation when working with insulation materials. Following these steps and consulting the relevant documentation ensures a safe and successful installation of the gas fireplace insert.

Install A Gas Fireplace Framing Finishing Pt 2 Diy Living Room Remodel

I Built A Fireplace Easier Than Thought

Gas Fireplace Installation How To Install A Diy

Fireplace Insert Framing

How To Install A Gas Fireplace Framing Finishing

Fireplace Framing

Wfsites Page Not Found

How To Frame A Fireplace

How To Install A Gas Fireplace Diy Built In

How To Frame And Build A Fireplace

Related Posts