Building A Fireplace Wall: A Comprehensive Guide

A fireplace wall serves as the focal point of a living space, offering both aesthetic appeal and functional warmth. Constructing a fireplace wall is a multifaceted project requiring careful planning, adherence to building codes, and proficient execution. This article details the essential steps involved in building a fireplace wall, from initial design considerations to final finishing touches.

The initial stages of planning are paramount. A structural engineer or qualified contractor should be consulted to assess the existing structure and confirm its ability to support the added weight of the fireplace and wall. This assessment will also dictate the suitability of different materials and construction methods. Local building codes and regulations must be thoroughly researched and followed to ensure the project's legality and safety. Permits are often required for fireplace installations and associated structural modifications.

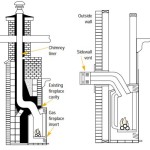

Different fireplace options, such as wood-burning, gas, or electric, influence the construction requirements. Wood-burning fireplaces necessitate a chimney or flue system designed to safely vent combustion byproducts. Gas fireplaces require a gas line installation by a licensed professional. Electric fireplaces, while simpler to install, still require proper electrical wiring and a dedicated circuit to handle the power load. The chosen fireplace type will significantly impact the materials and methods used in building the fireplace wall.

Key Point 1: Design and Material Selection

The design of the fireplace wall should complement the existing architectural style and interior design. The size, shape, and proportions of the wall must be carefully considered to ensure visual harmony. A wide range of materials can be used for the fireplace wall, including brick, stone, tile, concrete, wood, and various manufactured products. Each material possesses distinct aesthetic qualities, durability characteristics, and installation requirements.

Brick offers a classic and timeless look, providing excellent heat retention and durability. Stone provides a more rustic and natural appearance, but its weight and cost can be significant factors. Tile offers a wide variety of colors, patterns, and textures, allowing for a highly customized design. Concrete can be molded into various shapes and finishes, providing a contemporary and industrial aesthetic. Wood adds warmth and character, but it must be properly treated and protected from heat to prevent fire hazards. Manufactured stone veneers offer a cost-effective alternative to natural stone, replicating its appearance while being lighter and easier to install.

The selection of materials must also consider the fireplace's heat output and the proximity of combustible materials. Non-combustible materials, such as brick, stone, and concrete, are ideal for areas directly surrounding the firebox. Heat shields or insulation may be required to protect combustible materials, such as wood framing, from excessive heat exposure. The manufacturer's specifications for the fireplace installation typically outline the required clearances and safety precautions.

Detailed drawings and plans are essential for translating the design concept into a tangible structure. These plans should include precise measurements, material specifications, and construction details. A 3D rendering can help visualize the finished product and identify potential design flaws before construction begins. The plans should also indicate the location of electrical outlets, gas lines, and any other utilities that need to be incorporated into the fireplace wall.

Key Point 2: Framing and Structural Support

The framing of the fireplace wall provides the structural support for the chosen materials and the fireplace unit itself. Typically, the framing is constructed using wood studs, but steel studs may be preferred for certain applications, particularly those requiring greater fire resistance. The framing must be securely attached to the existing structure, using appropriate fasteners and anchoring techniques. The spacing of the studs depends on the weight of the materials being used and the load-bearing requirements.

Specific framing considerations apply to wood-burning fireplaces. The chimney or flue system requires a dedicated chase, which is a framed enclosure that extends from the fireplace to the roof. The chase must be constructed with fire-resistant materials and properly insulated to prevent heat loss and protect the surrounding structure. The framing around the firebox must adhere to strict clearance requirements to prevent the risk of fire. Non-combustible materials, such as cement board or metal studs, may be required in close proximity to the firebox.

For gas fireplaces, the framing must accommodate the gas line connections and ensure proper ventilation. Gas lines should be installed by a licensed plumber or gas fitter, following all applicable codes and regulations. Electric fireplaces require electrical wiring and a dedicated circuit to handle the power load. The wiring must be installed by a qualified electrician, adhering to all safety standards.

The framing must be plumb, level, and square to ensure a professional and aesthetically pleasing finish. Laser levels and other precision tools can be used to ensure accurate alignment. Any imperfections in the framing can become apparent during the finishing stages, compromising the overall appearance of the fireplace wall.

Key Point 3: Installation and Finishing

The installation process varies depending on the chosen materials and the fireplace type. Brick and stone are typically installed using mortar, ensuring proper adhesion and structural integrity. Tile is installed using thin-set mortar, with grout filling the spaces between the tiles. Wood panels are attached to the framing using nails, screws, or adhesives. Manufactured stone veneers are installed using a combination of mortar and mechanical fasteners.

Careful attention must be paid to the alignment, spacing, and leveling of the materials during installation. Spacers can be used to maintain consistent joint widths between bricks, stones, or tiles. A level should be used frequently to ensure a flat and even surface. Any irregularities or imperfections should be corrected immediately to prevent them from becoming more pronounced in the finished product.

The finishing touches are crucial for creating a visually appealing and functional fireplace wall. Grouting the tiles or stones not only enhances the aesthetic appeal, but also provides a waterproof seal. Sealing the brick or stone can protect it from staining and moisture damage. Installing a mantel adds a decorative element and provides a surface for displaying objects. Adding trim or molding can create a more refined and polished look.

Safety is paramount throughout the installation process. Protective gear, such as gloves, safety glasses, and dust masks, should be worn at all times. Power tools should be used with caution, following all safety instructions. Proper ventilation is essential when working with materials that produce dust or fumes. Consult the manufacturer's instructions for the fireplace unit and all building materials to ensure proper installation and safe operation.

After the fireplace wall is completed, it is important to conduct a thorough inspection to ensure that all elements are properly installed and functioning correctly. The fireplace should be inspected by a qualified professional to verify that it meets all safety standards and is operating efficiently. Any necessary adjustments or repairs should be made promptly.

Building a fireplace wall is a substantial undertaking that combines structural, mechanical, and aesthetic considerations. Diligent planning, adherence to building codes, and meticulous execution are essential for achieving a safe, functional, and visually appealing result. Careful material selection, precise framing techniques, and attention to detail during installation and finishing will ensure that the fireplace wall becomes a cherished focal point in the home for years to come.

Regular maintenance is crucial for preserving the appearance and functionality of the fireplace wall. The chimney or flue system should be inspected and cleaned annually to prevent the buildup of creosote, which can pose a fire hazard. The fireplace and surrounding materials should be cleaned regularly to remove soot, dust, and other debris. Inspect the mortar joints between bricks or stones and repair any cracks or damage promptly. Inspect all electrical and gas connections annually by a qualified professional.

With proper care and maintenance, the fireplace wall will provide warmth, ambiance, and aesthetic pleasure for many years. It can become a gathering place for family and friends, creating lasting memories around the hearth.

Diy How To Build A Fireplace In One Weekend Whitney Hansen Money Coaching

Diy Fireplace Mantel And Surround Jenna Kate At Home

Diy How To Build A Fireplace In One Weekend Whitney Hansen Money Coaching

Diy Electric Fireplace Build Home Design A

How To Build A Fireplace Red Cottage Chronicles

How To Diy Built In Electric Fireplace Jenna Sue Design

How To Build A Diy Built In Fireplace With An Electric Insert The Creative Mom

How To Build A Faux Fireplace Mantel And Surround The Home Depot

Diy Fireplace Building Plans Healthy Grocery Girl

Diy Electric Fireplace Wall Step By Shiplap

Related Posts