Building A Fireplace Insert: A Comprehensive Guide

A fireplace insert is a self-contained heating appliance designed to be installed within an existing fireplace opening. It offers a more efficient and controlled heating solution compared to traditional open fireplaces, which are notorious for energy loss through the chimney. Building a fireplace insert, while a complex project, can be a rewarding endeavor for experienced DIY enthusiasts and tradespeople. This article provides a detailed guide outlining the key considerations, steps, and safety precautions involved in such a project.

Fireplace inserts are available in various fuel types, including wood, gas, and electric. This guide primarily focuses on the construction of a wood-burning fireplace insert, as it represents the most challenging and potentially rewarding type to build. However, many of the principles discussed are applicable, albeit with modifications, to other fuel types.

Before embarking on the construction of a fireplace insert, thorough planning and preparation are essential. This includes assessing the existing fireplace structure, selecting appropriate materials, understanding relevant building codes, and acquiring the necessary tools and skills. Failure to adequately address these preliminary steps can lead to safety hazards, structural issues, and non-compliance with local regulations.

Key Point 1: Assessing the Existing Fireplace and Chimney

The existing fireplace and chimney must be thoroughly inspected to ensure they are structurally sound and compatible with the intended fireplace insert. This assessment should be performed by a qualified professional, such as a structural engineer or a certified chimney sweep. The following aspects should be carefully examined:

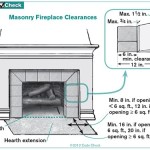

Firebox Dimensions: The firebox opening and depth must be measured accurately to determine the maximum size of the fireplace insert that can be accommodated. Sufficient clearance around the insert is crucial for proper ventilation and to prevent overheating.

Chimney Condition: The chimney must be inspected for cracks, deterioration, and obstructions. A damaged or obstructed chimney poses a significant fire hazard and can lead to carbon monoxide poisoning. The chimney liner, if present, should also be inspected for integrity. In many cases, a new chimney liner will be required when installing a fireplace insert, especially if the existing liner is damaged or incompatible with the insert's exhaust requirements.

Hearth Extension: The hearth extension, the non-combustible flooring in front of the fireplace opening, must meet or exceed minimum code requirements. This is essential to protect the surrounding flooring from sparks and embers that may escape from the fireplace insert.

Structural Integrity: The overall structural integrity of the fireplace and chimney must be assessed. Any structural deficiencies, such as crumbling bricks or unstable support, must be addressed before installing the fireplace insert.

Local Building Codes: It is imperative to consult with local building officials to determine the specific codes and regulations that apply to fireplace insert installations. These codes will vary depending on the jurisdiction and may cover aspects such as chimney height, clearances to combustible materials, and venting requirements.

Key Point 2: Material Selection and Design Considerations

The materials used to construct a fireplace insert must be durable, heat-resistant, and capable of withstanding the harsh conditions within the firebox. The design of the insert should prioritize safety, efficiency, and ease of use.

Steel: Steel is the most common material used for the firebox and other structural components of a wood-burning fireplace insert. It is strong, durable, and readily available. The thickness of the steel will depend on the size and intended use of the insert, but a minimum thickness of 1/4 inch is generally recommended for the firebox itself.

Firebrick: Firebrick is a refractory material that is designed to withstand extremely high temperatures. It is used to line the interior of the firebox, protecting the steel from direct exposure to the flames and helping to retain heat. The firebrick should be arranged in a manner that maximizes heat retention and reflects heat back into the firebox.

Insulation: Insulation is used to minimize heat loss from the fireplace insert and to protect surrounding combustible materials. Ceramic fiber blankets or boards are commonly used for this purpose. The insulation should be carefully installed to ensure there are no gaps or voids that could allow heat to escape.

Door and Glass: The door of the fireplace insert should be made of cast iron or steel and should be fitted with high-temperature glass. The glass allows for viewing of the fire while preventing sparks and embers from escaping. The door should also have a tight seal to prevent air leaks, which can reduce the efficiency of the insert.

Venting System: The venting system is crucial for safely and efficiently removing exhaust gases from the fireplace insert. As previously mentioned, a new chimney liner is often required. The liner should be made of stainless steel and should be sized according to the manufacturer's specifications. The venting system should also include a damper to control the airflow and prevent backdrafting.

Air Control System: An effective air control system is essential for regulating the combustion process and maximizing the efficiency of the fireplace insert. This system should allow for precise control of the primary and secondary air supply, enabling the user to adjust the burn rate and heat output. Secondary air injection is particularly important for achieving cleaner and more complete combustion.

Key Point 3: Fabrication and Installation Process

The fabrication and installation of a fireplace insert requires a high level of skill and attention to detail. It is recommended that only experienced welders and tradespeople undertake this project. Safety should be the top priority throughout the entire process.

Fabrication: The steel components of the fireplace insert should be cut and welded according to the design specifications. All welds should be strong, smooth, and airtight. The firebox should be constructed with precision to ensure a proper fit for the firebrick lining. Reinforcements may be necessary in areas subject to high stress.

Firebrick Installation: The firebrick should be carefully installed within the firebox, using fire-resistant mortar to secure it in place. The brick should be arranged in a tight, interlocking pattern to minimize gaps and ensure maximum heat retention.

Insulation Installation: The insulation should be installed around the exterior of the firebox, ensuring full coverage and eliminating any potential thermal bridges. The insulation should be secured with appropriate fasteners to prevent it from shifting or falling out of place.

Door Installation: The door should be securely mounted to the firebox, ensuring a tight seal. The hinges should be strong and durable, and the latch should be easy to operate. The glass should be properly installed and sealed to prevent air leaks.

Venting System Installation: The chimney liner should be carefully installed according to the manufacturer's instructions. It is crucial to ensure that the liner is properly connected to the fireplace insert and to the chimney top. All connections should be sealed to prevent leaks.

Insert Installation: The completed fireplace insert should be carefully positioned within the existing fireplace opening. Sufficient clearance should be maintained around the insert to allow for proper ventilation. The insert should be securely anchored to the fireplace structure to prevent it from shifting or tipping. Non-combustible materials must surround the insert to meet required safety standards.

Testing and Commissioning: After the fireplace insert has been installed, it should be thoroughly tested to ensure it is functioning properly. This includes checking for leaks, verifying the airflow, and monitoring the temperature of surrounding surfaces. A qualified professional should perform a final inspection to ensure the installation meets all applicable codes and regulations.

Building a fireplace insert is a complex project that requires careful planning, meticulous execution, and a thorough understanding of safety principles. By following the guidelines outlined in this article, experienced DIY enthusiasts and tradespeople can successfully construct a safe, efficient, and reliable heating appliance.

Properly sizing the insert to the space being heated is important. An oversized insert will overheat the room, while an undersized one will struggle to maintain a comfortable temperature. Factors like room size, insulation levels, and climate should be considered when determining the appropriate insert size.

Regular maintenance is essential for ensuring the longevity and safety of the fireplace insert. This includes cleaning the chimney regularly, inspecting the firebox for cracks or damage, and replacing any worn or damaged components. A well-maintained fireplace insert will provide years of reliable and efficient heating.

Diy Fireplace With Electric Insert Angela Marie Made

How To Build A Diy Built In Fireplace With An Electric Insert The Creative Mom

Diy Fireplace With Electric Insert Angela Marie Made

How To Diy An Amazing Electric Fireplace Surround And Mantel Drawer

Diy Electric Fireplace Build

Diy Fireplace With Electric Insert Angela Marie Made

How To Build A Fireplace Red Cottage Chronicles

How To Build A Diy Fireplace With Electric Insert H2obungalow

Diy How To Build A Fireplace In One Weekend Whitney Hansen Money Coaching

How To Diy Built In Electric Fireplace Jenna Sue Design

Related Posts