Brick Veneer for Fireplace Hearths: Aesthetics, Functionality, and Installation

Fireplace hearths serve as both a functional and aesthetic component of a fireplace. Functionally, they provide a non-combustible surface that protects the surrounding flooring and walls from sparks and embers. Aesthetically, the hearth can be a focal point, contributing significantly to the overall style of the room. Among the various materials used for hearth construction, brick veneer offers a compelling combination of visual appeal, relative affordability, and ease of installation, making it a popular choice for homeowners and builders alike.

Brick veneer, unlike full-thickness brick, is a thin layer of brick material adhered to a substrate. This characteristic makes it significantly lighter and less expensive than traditional brick, while still providing the desired brick aesthetic. The use of brick veneer for fireplace hearths presents several advantages, which will be explored in detail. This article aims to provide a comprehensive overview of brick veneer for fireplace hearths, discussing its benefits, material options, installation process, and considerations for safety and maintenance.

Advantages of Using Brick Veneer for Fireplace Hearths

Brick veneer provides a number of advantages over other hearth materials, including full brick, stone, and concrete. These advantages contribute to its increasing popularity in both new construction and fireplace remodeling projects.

Firstly, the cost-effectiveness of brick veneer is a significant draw. Because it is thinner and lighter than full-thickness brick, it requires less material and less structural support. This translates into lower material costs and potentially reduced labor costs, especially in renovation projects where adding significant weight to an existing structure can be problematic and expensive. Also, the reduced weight makes transportation and handling easier.

Secondly, brick veneer offers significant design flexibility. It is available in a wide variety of colors, textures, and sizes, allowing homeowners to achieve a specific aesthetic. Whether the desired effect is a rustic, traditional look or a more modern, clean appearance, there are brick veneer options available to suit nearly any design preference. Furthermore, brick veneer can be cut and shaped to fit around existing structures or to create custom hearth designs. This adaptability makes it a versatile choice for both new construction and renovation projects.

Thirdly, the relatively easy installation process is another notable advantage. While installing any fireplace hearth requires careful attention to detail and adherence to building codes, brick veneer is generally easier to work with than full-thickness brick or heavy stone slabs. The lighter weight reduces the physical demands of the installation, and the thinner profile allows for easier cutting and shaping. A skilled DIYer can often install brick veneer with the appropriate tools and guidance, potentially saving on labor costs. However, it's always recommended to consult with a professional before undertaking such a project, especially if unfamiliar with masonry techniques or local building codes.

Finally, the durability and low maintenance requirements of brick veneer are compelling. Brick is a naturally durable material, and while veneer is thinner than full brick, it still provides excellent resistance to heat, scratches, and impacts. Once installed, brick veneer requires minimal maintenance. Regular cleaning with a mild detergent and water is typically sufficient to keep it looking its best. It is also significantly easier to repair a damaged section of brick veneer compared to repairing damage to a solid stone or concrete hearth.

Material Options and Considerations

When choosing brick veneer for a fireplace hearth, several material options are available, each with its own characteristics and aesthetic appeal. The selection depends on factors such as budget, desired appearance, and the surrounding décor.

Clay brick veneer is the most common type. It is made from fired clay, just like traditional brick, and offers a classic, authentic look. Clay brick veneer is available in a wide range of colors and textures, from smooth, uniform bricks to rough, weathered ones. It is a durable and fire-resistant option, making it well-suited for fireplace hearths. The natural variations in color and texture within clay brick veneer contribute to its unique aesthetic appeal.

Manufactured brick veneer, also known as faux brick, is made from concrete or other composite materials. It is designed to mimic the look and feel of real brick but is generally lighter and less expensive. Manufactured brick veneer is also available in a wide range of colors, textures, and styles, often offering more consistent colors and patterns than natural clay brick. While generally durable, it might not have the same level of fire resistance as clay brick veneer, so it's essential to check the manufacturer's specifications to ensure it is suitable for use around a fireplace. The uniformity of manufactured brick can be seen as both an advantage and a disadvantage, depending on the desired look.

Thin brick veneer is another option, essentially a thinner version of clay brick veneer. It offers the same advantages as clay brick veneer but with an even lighter weight and thinner profile. This can be particularly useful in renovation projects where space is limited or where adding weight is a concern. Thin brick veneer is also easier to cut and shape, making it a good choice for intricate designs.

Regardless of the chosen material, it's crucial to ensure that the brick veneer is rated for use around fireplaces. This means it must be capable of withstanding high temperatures without cracking or deteriorating. Always consult the manufacturer's specifications and local building codes to ensure compliance. Also, consider the overall aesthetic of the room and choose a brick veneer style that complements the existing décor. Factors such as color, texture, and size should all be taken into account to create a cohesive and visually appealing fireplace hearth.

Installation Process and Safety Considerations

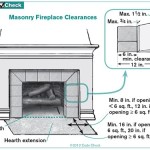

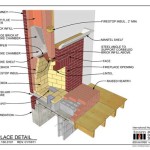

The installation of brick veneer for a fireplace hearth requires careful planning and execution to ensure a safe and aesthetically pleasing result. While the process is generally straightforward, it's essential to have a solid understanding of masonry techniques and building codes.

Firstly, proper preparation of the substrate is crucial. The substrate is the surface to which the brick veneer will be adhered. It must be clean, level, and structurally sound. Common substrate materials include concrete, cement board, and plywood. If using plywood, it must be fire-resistant and properly supported. All dust, dirt, and debris must be removed before applying the brick veneer. Any imperfections in the substrate should be addressed to ensure a smooth and even surface.

Secondly, choosing the right mortar and adhesive is essential. The mortar is the material that binds the brick veneer to the substrate and provides structural support. It must be specifically designed for use with brick veneer and rated for high-temperature applications. The adhesive is used to initially hold the brick veneer in place while the mortar cures. Both the mortar and adhesive should be compatible with the brick veneer material and the substrate. Following the manufacturer's instructions for mixing and applying the mortar and adhesive is crucial for a successful installation.

Thirdly, the actual installation process involves carefully applying the mortar to the back of each brick veneer piece and pressing it firmly against the substrate. Spacers are typically used to maintain consistent gaps between the bricks, creating a uniform look. The brick veneer should be installed in a staggered pattern, similar to traditional bricklaying, to enhance its visual appeal and structural integrity. Excess mortar should be removed from the joints as it cures to create a clean and professional finish. It is important to use a level and ensure each brick is aligned correctly.

Safety precautions are paramount during the installation process. Wearing safety glasses, gloves, and a dust mask is essential to protect oneself from mortar, dust, and debris. When cutting brick veneer, use a wet saw or a masonry saw with a dust collection system to minimize airborne dust. Ensure proper ventilation in the work area. Adhering to all safety guidelines and building codes is critical to ensure a safe and durable fireplace hearth.

Finally, after the brick veneer is installed, it's important to allow the mortar to cure completely before using the fireplace. The curing time will vary depending on the type of mortar used and the environmental conditions. Following the manufacturer's recommendations for curing time is crucial to ensure the mortar reaches its full strength. Once the mortar is fully cured, the fireplace hearth can be safely used and enjoyed.

How To Install Thin Brick Veneers On Your Fireplace

Building An Electric Fireplace With Brick Facade

Refacing A Fireplace With Stone Veneer Horizon

Fireplace Mantel Surround Brick Veneer Sunny Side Design

7 Popular Stone Veneer Fireplace Design Trends Mason S Mark

Crisp Brick Takes Fireplace From Dull To Dazzling Heat Glo

Prestige Stone Veneer Fireplace Surround Fusion Family Room New York By Weckesser Brick Co Inc Houzz

Thin Brick Wood Stove Surround Looks Great Feels Toasty

Thin Brick Wood Stove Surround Looks Great Feels Toasty

Fireplace Mantel Surround Brick Veneer Sunny Side Design