Antique Gas Fireplace Insert Restoration: A Comprehensive Guide

Antique gas fireplace inserts offer a unique blend of historical charm and modern convenience. These units, often dating back to the late 19th and early 20th centuries, were designed to easily convert existing fireplaces into gas-fueled heating sources. However, due to their age and the wear and tear associated with decades of use, many antique gas fireplace inserts require restoration to function safely and efficiently. The restoration process involves careful assessment, meticulous cleaning, component repair or replacement, and adherence to modern safety standards.

The value of a restored antique gas fireplace insert extends beyond its functional capabilities. These inserts serve as focal points in a room, adding character and a touch of historical elegance. A well-restored unit can become a conversation piece, showcasing craftsmanship and design sensibilities from a bygone era. Moreover, restoring an antique unit is often more environmentally responsible than purchasing a new fireplace, as it prolongs the life of an existing product and reduces the demand for new manufacturing.

Understanding the Components of an Antique Gas Fireplace Insert

Before embarking on the restoration journey, it is crucial to understand the various components that comprise an antique gas fireplace insert. These components can vary slightly depending on the age and manufacturer of the unit, but common elements include:

The Firebox: This is the main body of the insert, typically constructed of cast iron. The firebox houses the burner assembly and is responsible for containing the flames. It is prone to rust and corrosion over time, which may require extensive cleaning and repair.

The Burner Assembly: This component delivers the gas to the fireplace and creates the flame. Common types of burner assemblies found in antique gas fireplace inserts include log lighters, radiant burners, and atmospheric burners. Burner assemblies often suffer from clogging, corrosion, and damaged orifices.

The Gas Valve: This valve controls the flow of gas to the burner assembly. It is a critical safety component and must be in good working order. Antique gas valves are typically manually operated and may require rebuilding or replacement.

The Pilot Light Assembly: The pilot light provides a continuous flame that ignites the main burner. This assembly includes the pilot burner, thermocouple, and sometimes a safety shut-off valve. Pilot light assemblies often experience issues with gas flow and thermocouple failure.

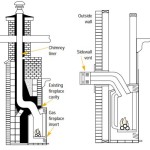

The Venting System: Antique gas fireplace inserts often rely on existing chimneys for venting exhaust gases. It is essential to ensure that the venting system is properly sized and installed to prevent carbon monoxide buildup. In some cases, the original venting may need to be upgraded to meet modern safety standards.

Decorative Elements: Many antique gas fireplace inserts feature decorative elements such as cast iron facings, ceramic logs, and ornate grates. These elements can be damaged or faded over time and may require cleaning, repair, or replacement to restore their original appearance.

The Restoration Process: A Step-by-Step Guide

Restoring an antique gas fireplace insert is a complex process that requires careful planning and execution. It is highly recommended to consult with a qualified professional, especially when dealing with gas lines and safety components. The following steps provide a general overview of the restoration process:

Initial Assessment: The first step is to thoroughly inspect the insert to assess its overall condition. This includes checking for rust, corrosion, cracks, and other damage to the firebox, burner assembly, gas valve, and venting system. Documenting the condition through photographs is also beneficial before beginning any work. Determining the make and model of the fireplace, if possible, will aid in finding replacement parts and understanding its original design.

Disassembly: Once the assessment is complete, carefully disassemble the insert. Label each component as it is removed to ensure proper reassembly. Pay close attention to the order in which the components are taken apart, as this will be helpful when putting the insert back together. Securely store all parts.

Cleaning: Thoroughly clean each component to remove rust, dirt, and debris. Wire brushes, sandpaper, and specialized cleaning solutions can be used for metal parts. For delicate parts, such as ceramic logs, use mild soap and water. Sandblasting may be required for heavily rusted or corroded components. Ensure all cleaning agents and methods are appropriate for the material of each component.

Repair and Replacement: Repair any damaged components whenever possible. Small cracks in the cast iron can be repaired using welding techniques. Corroded burner assemblies may need to be cleaned and rebuilt with new orifices. Replace any components that are beyond repair, such as cracked gas valves or severely damaged pilot light assemblies. Sourcing appropriate replacement parts may require extensive research. Consider using original parts if available, or compatible modern replacements. Always ensure that replacement parts meet or exceed the original specifications for safety and performance.

Gas Line Inspection and Testing: The gas line is a critical safety component and must be inspected and tested by a qualified professional. Check for leaks, corrosion, and proper connections. Replace any damaged or worn gas lines. A gas pressure test should be conducted to ensure that the gas pressure is within the proper range. Adhere to all local codes and regulations concerning gas line installation and safety.

Venting System Inspection: The venting system is responsible for safely removing exhaust gases from the fireplace. Inspect the chimney or vent pipe for obstructions, cracks, and other damage. Have the chimney professionally cleaned to remove creosote buildup. Ensure the venting system is properly sized and installed to meet modern safety standards. Consider installing a new vent liner if the existing chimney is damaged or inadequate.

Reassembly: Once all components have been cleaned, repaired, or replaced, carefully reassemble the insert. Refer to the diagrams and notes taken during disassembly to ensure that all components are properly positioned. Use new gaskets and seals as needed to prevent gas leaks. Apply appropriate lubricants to moving parts to ensure smooth operation.

Testing and Adjustments: After reassembly, test the insert to ensure that it is functioning properly. Check for gas leaks using a leak detector. Verify that the burner ignites smoothly and burns with a clean, blue flame. Adjust the gas pressure and air mixture as needed to optimize performance. Monitor the insert for any signs of overheating or malfunction. Conduct a thorough test burn to ensure proper and safe operation.

Safety Considerations for Antique Gas Fireplace Inserts

Due to their age, antique gas fireplace inserts may not incorporate the same safety features as modern units. It is essential to address these potential safety concerns during the restoration process:

Carbon Monoxide Detectors: Install carbon monoxide detectors in the room where the fireplace is located and in adjacent living areas. Carbon monoxide is a colorless, odorless gas that can be deadly. Ensure that the detectors are functioning properly and have fresh batteries.

Gas Leak Detection: Regularly check for gas leaks using a leak detector or soapy water. If a gas leak is detected, immediately shut off the gas supply and contact a qualified professional.

Venting System Maintenance: Regular maintenance of the venting system is crucial to prevent carbon monoxide buildup. Have the chimney professionally cleaned annually and inspect it for damage. Ensure that the venting system is properly sized and installed. Investigate any unusual smells, sounds or soot buildup around the fireplace or chimney.

Professional Inspection: Have the restored fireplace inspected by a qualified professional before using it regularly. The inspector can identify any potential safety hazards and ensure that the unit is operating properly. Schedule routine inspections as needed. A professional can assess the condition of the fireplace, including the gas line, burner, venting and components.

Adherence to Codes and Regulations: Ensure that the restoration process complies with all local codes and regulations pertaining to gas fireplace installations. Consult with local building inspectors or gas company representatives to obtain the necessary permits and approvals. Keeping up-to-date with code changes is crucial for maintaining a safe and compliant appliance.

By following these steps and prioritizing safety, it is possible to restore an antique gas fireplace insert to its former glory while ensuring its continued safe and efficient operation. The result is a beautiful and functional piece of history that can be enjoyed for years to come.

Antique Faceplates For Gas Inserts Specialty House

Gas Inserts For The Old Fireplaces San Francisco Victorian Restoration

Antique Faceplates For Gas Inserts Specialty House

Late 19th Century Fully Red Salvaged Chicago Dawson Brothers Interior Residential Fireplace Gas Insert

Domestic Fireplace Restoration Services In London

Antique Faceplates For Gas Inserts Specialty House

Victorian Fireplace Restoration Archives Antique Fireplaces Blog

The Antique Fireplace Co Cast Iron Victorian Fireplaces

Original Red Antique Cast Iron Arts Crafts Tiled Fireplace Insert Lg287

Antique Fireplaces Reion Styles Blog

Related Posts