What is a Fireplace Lintel?

A fireplace lintel is a crucial structural component of a fireplace system. It serves as a horizontal support beam that spans the opening of the firebox. Understanding the purpose, materials, installation, and potential issues related to a fireplace lintel is essential for homeowners, builders, and anyone involved in fireplace construction or maintenance.

The primary function of the fireplace lintel is to bear the weight of the masonry above the firebox opening. This includes the bricks or stones of the chimney, the chimney breast, and any other structural elements that rest on top of the firebox. Without a lintel, the weight would bear directly on the firebox walls, potentially causing them to crack, crumble, or even collapse over time.

The fireplace lintel acts as a load-bearing bridge, effectively distributing the weight across its span and transferring it to the surrounding walls or structural supports. This ensures the stability and integrity of the entire fireplace structure. Choosing the correct material and ensuring proper installation of the lintel are vital for the long-term safety and functionality of the fireplace.

Key Point 1: Materials Used for Fireplace Lintels

Fireplace lintels are typically constructed from materials that are durable, fire-resistant, and capable of withstanding high temperatures. The most common materials include steel, concrete, and stone.

Steel Lintels: Steel lintels are a popular choice due to their high strength and relatively low profile. They are capable of supporting significant weight over a wide span. Steel lintels are often fabricated from angle iron or other structural steel shapes, designed to meet specific load-bearing requirements. Steel lintels can be susceptible to rust if not properly protected, particularly in damp or outdoor environments. Therefore, they are often coated with a rust-resistant primer or paint before installation.

Concrete Lintels: Concrete lintels are another commonly used option, particularly in modern construction. They are typically precast and reinforced with steel rebar to increase their strength and prevent cracking. Concrete lintels offer good fire resistance and are relatively inexpensive compared to steel or stone. However, concrete can be porous and may absorb moisture over time, which can lead to deterioration, especially in freeze-thaw climates. Proper sealing and waterproofing can help mitigate this issue.

Stone Lintels: Stone lintels, such as limestone, sandstone, or granite, were traditionally used in older fireplaces and are often chosen for their aesthetic appeal. Stone lintels can be very strong and durable, providing excellent fire resistance. However, stone lintels are also generally more expensive and heavier than steel or concrete, requiring specialized installation techniques. The selection of stone must be appropriate for the local climate; some types of stone are more susceptible to weathering and erosion than others.

The choice of material will depend on several factors, including the size of the firebox opening, the weight of the masonry above, the aesthetic preferences of the homeowner, and the budget for the project. Consulting with a qualified structural engineer or fireplace professional is recommended to determine the most suitable material for a specific application.

Key Point 2: Installation of a Fireplace Lintel

Proper installation of a fireplace lintel is crucial for its structural integrity and the overall safety of the fireplace. Installation typically involves several steps, including preparing the firebox opening, setting the lintel in place, and securing it with mortar or appropriate fasteners.

Preparation: The first step is to ensure that the firebox opening is properly prepared. This involves removing any existing lintel, cleaning the surrounding masonry, and ensuring that the surfaces are level and plumb. It is essential to check the dimensions of the opening to ensure that the new lintel will fit correctly. Any gaps or irregularities can compromise the lintel's ability to support the weight above the firebox.

Setting the Lintel: The lintel is then carefully positioned over the firebox opening, ensuring that it is centered and level. A bed of mortar is typically applied to the top of the supporting walls to provide a stable and even bearing surface for the lintel. For heavier lintels, such as stone or concrete, mechanical lifting equipment may be required to safely position them. It is important to use the correct type of mortar recommended for the lintel material; for example, a lime-based mortar is often preferred for stone lintels.

Securing the Lintel: Once the lintel is in place, it is secured with mortar or fasteners, depending on the material and installation requirements. Mortar is used to fill any gaps between the lintel and the surrounding masonry, providing a tight and secure bond. Steel lintels may be anchored with bolts or welds to the surrounding structure for added stability. The mortar should be allowed to cure properly before any additional weight is applied to the lintel. It is important to follow the manufacturer's instructions and local building codes during the installation process.

Improper installation can lead to a number of problems, including cracks in the lintel, sagging, or even collapse. Therefore, it is highly recommended to hire a qualified mason or fireplace professional to install the lintel. They will have the necessary experience and knowledge to ensure that the lintel is installed correctly and safely.

Key Point 3: Potential Problems and Maintenance

Like any structural component, a fireplace lintel can experience problems over time due to exposure to heat, moisture, and other environmental factors. Regular inspection and maintenance are essential to identify and address any potential issues before they become serious.

Cracking: Cracking is a common problem in fireplace lintels, particularly those made of concrete or stone. Cracks can be caused by thermal stress, freeze-thaw cycles, or structural settlement. Small cracks may be cosmetic, but larger cracks can indicate a more serious structural problem. Any cracks should be inspected by a qualified professional to determine the cause and recommend appropriate repairs.

Rusting (Steel Lintels): Steel lintels are susceptible to rust, especially in damp or outdoor environments. Rust can weaken the lintel and compromise its ability to support weight. Regular inspection and maintenance, such as applying rust-resistant paint or coatings, can help prevent rusting. If significant rust is present, the lintel may need to be replaced.

Mortar Deterioration: The mortar surrounding the lintel can deteriorate over time due to weathering, erosion, or exposure to heat. Deteriorated mortar can weaken the bond between the lintel and the surrounding masonry, potentially leading to instability. Repointing, which involves removing and replacing the deteriorated mortar, can help restore the integrity of the structure.

Sagging: Sagging of the lintel can indicate a serious structural problem, often caused by overloading or inadequate support. A sagging lintel should be inspected immediately by a qualified professional to determine the cause and recommend necessary repairs or replacement. Ignoring a sagging lintel can lead to further damage to the fireplace and potentially pose a safety hazard.

Regular maintenance, such as cleaning the firebox and chimney, can also help prevent problems with the lintel. Removing soot and debris can reduce the risk of chimney fires, which can damage the lintel and surrounding masonry. It is also important to ensure that the chimney is properly ventilated to prevent moisture buildup, which can contribute to deterioration of the lintel and mortar.

In summary, the fireplace lintel is a vital structural component that supports the masonry above the firebox opening. Choosing the right material, ensuring proper installation, and performing regular maintenance are essential for the long-term safety and functionality of the fireplace. Addressing any potential problems promptly can help prevent more serious issues and ensure that the fireplace remains a safe and enjoyable part of the home.

Different types of fireplaces may have specific lintel requirements. For example, a large Rumford fireplace might necessitate a particularly robust lintel to handle the increased firebox opening. Similarly, outdoor fireplaces, being exposed to the elements, require lintels resistant to weathering and temperature fluctuations. Understanding these nuances ensures the appropriate selection and installation of a lintel for any given fireplace design.

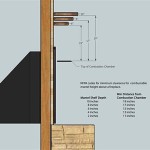

Building codes often stipulate minimum requirements for fireplace lintels, including material specifications, load-bearing capacities, and installation guidelines. Compliance with these codes is crucial for ensuring the safety and integrity of the fireplace structure. Local building departments can provide specific information on applicable codes in a given area. Consultations with structural engineers or experienced masons are also valuable in navigating code requirements and ensuring compliance.

The long-term performance of a fireplace lintel is directly linked to the quality of materials used and the precision of installation. While cost-saving measures might seem appealing initially, they can lead to premature deterioration and costly repairs down the line. Investing in high-quality materials and professional installation is a worthwhile investment that ensures the longevity and safety of the fireplace system.

What Is The Fireplace Lintel Why It Important

What Is A Fireplace Lintel Home Inspection Geeks

Understanding The Anatomy Of A Fireplace Madewell Masonry

Fireplace Lintels A Complete Guide With S

Chimney 101 Firebox Assembly

Fireplace Lintels A Complete Guide With S

Three Reasons Never To Remove A Fireplace Lintel Swede Chimney Sweep Dryer Vent Cleaning

Fireplace Lintel Questions Fix Community Forum

Fireplace Lintels A Complete Guide With S

What Is A Fireplace Lintel Home Inspection Geeks

Related Posts