Understanding Gas Fireplace Pipe: A Comprehensive Guide

Gas fireplaces offer a convenient and efficient way to enjoy the ambiance and warmth of a fire without the need for wood. A crucial yet often overlooked component of a gas fireplace system is the piping that delivers the gas fuel. This article will delve into the various aspects of gas fireplace pipe, covering its types, materials, installation requirements, safety considerations, and maintenance guidelines.

The primary function of gas fireplace pipe is to safely transport natural gas or propane from the gas supply line to the fireplace burner. Improper pipe selection, installation, or maintenance can lead to gas leaks, fires, or explosions, highlighting the importance of understanding the intricacies of this component.

Types of Gas Fireplace Pipe

Several types of piping are commonly used for gas fireplace installations, each with its specific applications and characteristics. The selection depends on factors such as the type of fuel (natural gas or propane), the distance from the gas meter, and any local building codes.

Black Iron Pipe: This is a traditional and robust option, frequently employed for natural gas lines. It is made of steel and coated with a black oxide finish to resist corrosion, although this coating is not entirely rustproof. Black iron pipe is known for its durability and resistance to high pressures, making it suitable for longer runs and larger gas appliances. It requires threading and the use of pipe dope or Teflon tape to create gas-tight seals at each joint. While durable, black iron pipe can be more challenging to install than other options due to its rigidity and the need for specialized tools for cutting and threading.

Galvanized Steel Pipe: Similar to black iron pipe, galvanized steel pipe is also made of steel but is coated with a layer of zinc to provide enhanced corrosion resistance. While galvanized steel is more resistant to rust than black iron, it is generally not recommended for gas lines due to the potential for the zinc coating to react with certain components in natural gas, potentially forming harmful deposits that can clog the gas line. In many jurisdictions, its use for gas piping is prohibited.

Copper Pipe: Copper pipe, particularly Type L or Type K, is a popular choice for gas lines due to its flexibility, corrosion resistance, and ease of installation. It can be joined using soldering or flaring techniques, creating reliable and leak-proof connections. Copper is also less susceptible to corrosion from moisture and chemicals commonly found in residential environments. However, copper pipe can be more expensive than steel alternatives and may be susceptible to damage from physical impacts. Its application might be limited by local codes or regulations for gas fireplace installations.

Corrugated Stainless Steel Tubing (CSST): CSST is a flexible piping system made of corrugated stainless steel covered with a yellow or black polyethylene jacket. This type of pipe is often preferred for its ease of installation, as it can be bent and routed around obstacles without the need for numerous fittings. CSST is commonly used for both natural gas and propane installations. However, it is crucial to properly bond CSST to the electrical grounding system to protect it from lightning strikes and electrical surges, which can cause pinhole leaks and potentially ignite the gas. The bonding requirements for CSST are often specified in local building codes and manufacturer instructions.

Polyethylene Pipe: Polyethylene pipe is sometimes used for underground gas lines, particularly for connecting propane tanks to the house. It's flexible, resistant to corrosion, and relatively inexpensive. However, it requires specialized fittings and installation techniques, and it's not suitable for above-ground applications within the building. Local codes should be consulted to verify its acceptability.

Installation Requirements and Safety Considerations

Proper installation is paramount when dealing with gas fireplace pipe to prevent leaks and ensure safe operation. It is highly recommended that only qualified and licensed professionals perform gas line installations or modifications. These professionals are trained in gas fitting techniques and are familiar with local building codes and safety regulations.

Code Compliance: Gas line installations must comply with local building codes and the National Fuel Gas Code (NFPA 54) or the International Fuel Gas Code (IFGC). These codes specify requirements for pipe sizing, materials, installation methods, and testing procedures. Failure to comply with these codes can result in fines, permit rejections, or, more importantly, pose a significant safety hazard.

Pipe Sizing: Proper pipe sizing is crucial to ensure that the gas fireplace receives an adequate supply of fuel at the correct pressure. Undersized pipes can restrict gas flow, leading to poor performance or even flameout. Oversized pipes, while not necessarily dangerous, can be unnecessarily expensive. Pipe sizing calculations take into account the length of the pipe, the number of fittings, the gas pressure, and the BTU input rating of the fireplace.

Jointing and Sealing: All pipe joints must be properly sealed to prevent gas leaks. For threaded pipe connections, pipe dope or Teflon tape should be applied to the threads before assembly. These sealants create a gas-tight barrier and prevent corrosion. Soldered or flared connections should be made according to industry best practices, ensuring clean surfaces and proper heating techniques. CSST connections require specialized fittings that are designed to create a secure and leak-proof seal.

Leak Testing: After installation or modification of any gas piping, a leak test must be performed to verify the integrity of the system. The typical procedure involves pressurizing the pipe with air or an inert gas (such as nitrogen) and monitoring the pressure for any drop over a specific period. A soap solution can also be applied to the joints to check for bubbles, which indicate leaks. Any leaks must be promptly repaired before the gas supply is turned on.

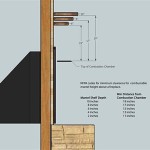

Clearances and Protection: Gas pipes should be installed with adequate clearance from other utilities, such as electrical wiring and water pipes. They should also be protected from physical damage, such as impacts from tools or equipment. In areas where the pipe is exposed to potential damage, it should be protected by sleeves or guards.

Grounding and Bonding (CSST): As mentioned earlier, CSST requires proper grounding and bonding to protect it from lightning strikes and electrical surges. The bonding wire should be sized according to the manufacturer's instructions and connected to the main electrical grounding system. This helps to dissipate any electrical current that may travel through the pipe, preventing pinhole leaks and potential fires.

Emergency Shut-Off Valve: A readily accessible emergency shut-off valve should be installed upstream of the gas fireplace. This valve allows the gas supply to be quickly shut off in the event of a leak or other emergency. The location of the shut-off valve should be clearly marked, and all occupants of the building should be familiar with its operation.

Maintaining Gas Fireplace Pipe for Longevity and Safety

Regular maintenance is essential to ensure the continued safe and efficient operation of gas fireplace pipe. This includes periodic inspections, leak testing, and proper ventilation.

Visual Inspections: Periodically inspect the gas pipe for any signs of corrosion, damage, or loose connections. Look for rust, dents, or kinks in the pipe. Check the fittings for any signs of leakage, such as stains or discoloration. If any issues are found, contact a qualified technician for inspection and repair.

Leak Testing (Scheduled): While a leak test is crucial after installation, regular leak tests, even without apparent issues, are good preventative maintenance. Using a soap solution around joints and connections is a straightforward method to check for minor leaks that might otherwise go unnoticed. Schedule professional testing periodically to ensure the integrity of the entire system.

Ventilation: Ensure that the area around the gas fireplace is adequately ventilated. This helps to prevent the buildup of carbon monoxide, a colorless and odorless gas that can be produced by incomplete combustion. Install a carbon monoxide detector near the fireplace and test it regularly.

Professional Servicing: Schedule regular servicing of the gas fireplace by a qualified technician. The technician will inspect the gas line, burner, and other components of the fireplace to ensure that they are in good working order. They will also clean the burner and check the gas pressure to ensure proper combustion.

Avoiding Modifications: Avoid making any unauthorized modifications to the gas piping system. Any changes to the piping, fittings, or gas pressure should be performed by a licensed professional. Unauthorized modifications can compromise the safety of the system and potentially void the warranty.

Component Replacement: Over time, certain components of the gas fireplace system, such as the gas valve or burner, may need to be replaced. Use only approved replacement parts that are specifically designed for the fireplace. Using non-approved parts can affect the performance and safety of the fireplace.

By understanding the types of gas fireplace pipe, adhering to proper installation procedures, and performing regular maintenance, homeowners can enjoy the warmth and ambiance of a gas fireplace safely and efficiently for many years. Prioritizing safety and code compliance is crucial to prevent potential hazards and ensure the longevity of the gas fireplace system.

Vented Vs B Vent Direct Free Dixie S

How To Install A Log Lighter Fireplace Gas Starter Pipe

Lp Gas Line Clearance Plumbing Inspections Internachi Forum

Gas Fireplace Starters Log Lighter Universal

Understanding How Direct Vent Works Heat Glo

Dante Stainless Steel Gas Fireplace Log Lighter Burner Pipe With T Mixer

What Is A Direct Vent Fireplace Vertical Chimney Care

How To Light A Gas Fireplace

Do Gas Fireplaces Need A Chimney Dreifuss

Do Gas Fireplaces Need A Chimney Dreifuss