How to Make a Fireplace: A Comprehensive Guide

Constructing a fireplace is a significant undertaking that requires careful planning, adherence to building codes, and a thorough understanding of both structural and combustion principles. This article provides a comprehensive guide to the process of building a fireplace, covering design considerations, material selection, structural elements, and safety precautions.

The design phase is paramount to the success of any fireplace project. This involves determining the desired size and style of the fireplace, as well as its placement within the structure. Considerations such as the overall aesthetics of the room, existing architectural features, and the available space will all influence the final design. It is also crucial to consider the type of fuel the fireplace will burn – wood, gas, or electric – as this will impact the necessary components and construction methods.

Local building codes and regulations must be strictly adhered to. These codes often dictate specific requirements for fireplace construction, including chimney height, firebox dimensions, clearances from combustible materials, and ventilation requirements. Consulting with local building authorities and obtaining the necessary permits before commencing construction is essential for ensuring compliance and avoiding potential legal issues. Professional consultation with a qualified architect or structural engineer may also be necessary, particularly for complex or load-bearing fireplace designs.

Key Point 1: Foundation and Hearth Construction

The foundation is the critical base upon which the entire fireplace structure rests. It must be designed to support the considerable weight of the fireplace and chimney, typically constructed from reinforced concrete. The foundation should extend below the frost line to prevent movement due to freezing and thawing cycles. The dimensions of the foundation will depend on the size and weight of the fireplace, but it should generally be wider than the base of the firebox to provide adequate support.

The hearth is the non-combustible area in front of the firebox that protects the surrounding floor from sparks and embers. It usually consists of a layer of brick, stone, or concrete laid on top of a concrete slab. The hearth must extend a minimum distance from the firebox opening, as specified by local building codes. This distance varies depending on the size of the firebox opening and the type of fuel being burned. A typical requirement is at least 16 inches in front of the firebox and 8 inches on either side.

Construction of the hearth begins with pouring a concrete slab that is level with the finished floor. The hearth material, such as brick or stone, is then laid on top of the slab using mortar. The mortar joints should be carefully filled and tooled to provide a smooth and durable surface. The hearth should be level and free of any cracks or gaps that could allow embers to fall through. The transition between the hearth and the adjacent flooring should be seamless and visually appealing.

Key Point 2: Firebox and Smoke Chamber Construction

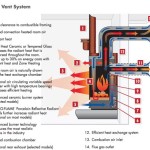

The firebox is the chamber where the fire is contained. It must be constructed from fire-resistant materials such as firebrick, which is designed to withstand the high temperatures generated by burning fuel. The dimensions of the firebox will influence the efficiency and draft of the fireplace. A properly sized firebox will allow for efficient combustion and prevent smoke from entering the room.

Firebrick is typically laid using a high-temperature refractory mortar. The mortar joints should be as thin as possible to minimize heat loss. The firebrick should be arranged in a tight, interlocking pattern to create a strong and durable firebox. Expansion joints should be included in the firebox construction to allow for thermal expansion and contraction, preventing cracking. The back and side walls of the firebox should be sloped slightly inward to help reflect heat into the room.

The smoke chamber is the area above the firebox that channels smoke and gases into the chimney. It should be constructed with smooth, angled walls to promote a smooth flow of smoke and prevent turbulence. The smoke chamber often tapers upward to create a more efficient draft. The materials used for the smoke chamber should also be fire-resistant, such as firebrick or refractory concrete.

The damper is a crucial component located at the top of the firebox, controlling the airflow through the chimney. A properly functioning damper can improve the efficiency of the fireplace and prevent heat loss when the fireplace is not in use. Dampers are typically made of cast iron or stainless steel and can be operated manually or automatically. The damper should be located in a readily accessible location for easy operation and maintenance.

Key Point 3: Chimney Construction and Safety Considerations

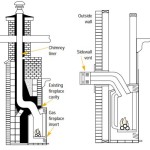

The chimney is the vertical structure that carries smoke and gases away from the firebox. The height of the chimney is critical for creating adequate draft and preventing smoke from entering the room. Building codes typically specify minimum chimney heights based on the roof pitch and surrounding structures. A chimney that is too short can result in poor draft and smoke problems, while a chimney that is too tall can be unsightly and structurally unstable.

Chimneys can be constructed from various materials, including brick, stone, concrete block, or prefabricated metal. Brick and stone chimneys are aesthetically pleasing and durable but require skilled craftsmanship. Concrete block chimneys are more economical but may not be as visually appealing. Prefabricated metal chimneys are lightweight and easy to install but may not have the same aesthetic appeal as masonry chimneys.

A chimney liner is a protective lining that runs the length of the chimney, preventing corrosive gases from damaging the chimney structure. Chimney liners are typically made of clay tile, stainless steel, or cast-in-place concrete. A properly installed chimney liner can significantly extend the lifespan of the chimney and improve its safety and performance. It is crucial to inspect the chimney periodically for cracks or damage and repair them promptly.

Safety is paramount when constructing and using a fireplace. Proper clearances from combustible materials must be maintained to prevent fires. Building codes specify minimum clearances for combustible materials such as wood framing, wall coverings, and roofing materials. These clearances should be strictly adhered to during construction. The area around the fireplace should be kept free of flammable materials such as curtains, rugs, and furniture.

Carbon monoxide detectors should be installed in any home with a fireplace. Carbon monoxide is a colorless, odorless gas that can be produced by incomplete combustion. It is extremely dangerous and can be fatal. Carbon monoxide detectors provide an early warning of carbon monoxide buildup, allowing occupants to evacuate the premises safely. The detectors should be placed near sleeping areas and tested regularly to ensure they are functioning properly.

Regular chimney maintenance is essential for ensuring safe and efficient fireplace operation. The chimney should be inspected and cleaned annually by a qualified chimney sweep. Creosote, a flammable byproduct of wood burning, can accumulate in the chimney and pose a fire hazard. Regular cleaning removes creosote buildup and prevents chimney fires. The chimney sweep should also inspect the chimney for any signs of damage or deterioration and recommend necessary repairs.

The selection of appropriate fuel is also crucial for safe and efficient fireplace operation. Seasoned firewood is the preferred fuel for wood-burning fireplaces. Seasoned firewood has been dried for at least six months and has a moisture content of less than 20%. Burning wet or unseasoned firewood can result in poor combustion, excessive smoke, and creosote buildup. The type of wood also affects its burning characteristics. Hardwoods such as oak and maple burn longer and produce more heat than softwoods such as pine and fir.

Gas fireplaces require a gas line connection, which must be installed by a qualified professional. The gas line should be leak-tested and inspected regularly to ensure it is in good working condition. The fireplace should be operated according to the manufacturer's instructions. Electric fireplaces do not require a chimney or gas line and can be installed in virtually any room. However, they may not provide the same level of heat as wood or gas fireplaces.

How To Build A Fireplace Red Cottage Chronicles

How To Build A Fireplace Red Cottage Chronicles

How To Build A Diy Stone Fireplace Boxwood Design Co

How To Build An Indoor Fireplace The Constructor

How To Design And Build Gorgeous Diy Fireplace Built Ins A Home

How To Make An Easy Diy Fireplace Mantel Sprucing Up Mamahood

Building A Fireplace Fine Homebuilding

How To Build An Indoor Fireplace The Constructor

Diy Fireplace Mantel And Surround Jenna Kate At Home

How I Built A Faux Modern Farmhouse Fireplace Anderson Grant

Related Posts