Woodburning Fireplace Inserts: A Comprehensive Guide

Woodburning fireplace inserts offer an efficient and aesthetically pleasing method for heating homes. These inserts are essentially self-contained wood-burning stoves designed to fit directly into an existing masonry fireplace. They provide numerous benefits over traditional open fireplaces, including increased heating efficiency, reduced emissions, and enhanced safety. This article will explore the various aspects of woodburning fireplace inserts, encompassing their functionality, advantages, selection criteria, installation considerations, and maintenance requirements.

Traditional masonry fireplaces, while visually appealing, are often inefficient heating sources. A significant portion of the heat generated in an open fireplace is lost up the chimney, contributing to heat loss within the house. This inefficiency can result in higher heating bills and a less comfortable indoor environment. Woodburning fireplace inserts address this issue by containing the fire within a closed firebox, maximizing heat radiation and minimizing heat loss. The controlled combustion process also reduces the amount of smoke and pollutants released into the atmosphere.

Enhanced Heating Efficiency and Emission Reduction

The primary advantage of a woodburning fireplace insert is its improved heating efficiency compared to a traditional open fireplace. Inserts are designed with a closed combustion chamber, which allows for a more controlled and complete burning process. This results in increased heat output and reduced fuel consumption. The firebox is typically constructed from cast iron or steel, materials known for their excellent heat retention and radiation properties. These materials absorb heat from the burning wood and radiate it into the room, providing a more consistent and effective heating source.

Furthermore, many modern woodburning fireplace inserts incorporate advanced combustion technologies, such as secondary combustion systems and catalytic combustors. These systems help to burn off the smoke and gases that are produced during the initial combustion process, further reducing emissions and increasing efficiency. Secondary combustion systems introduce preheated air into the firebox, which ignites unburned gases, resulting in a cleaner burn. Catalytic combustors use a coated ceramic honeycomb to facilitate the combustion of gases at a lower temperature, further reducing emissions. Inserts certified by the Environmental Protection Agency (EPA) meet stringent emission standards, ensuring cleaner air quality.

The efficiency of a woodburning fireplace insert is typically measured by its heating efficiency rating, which indicates the percentage of energy from the wood that is converted into usable heat. EPA-certified inserts often have heating efficiency ratings of 70% or higher, significantly exceeding the efficiency of open fireplaces, which can be as low as 10-20%. This increased efficiency translates to substantial savings on heating costs and a reduced environmental impact.

Choosing the Right Woodburning Fireplace Insert

Selecting the appropriate woodburning fireplace insert requires careful consideration of several factors, including the size of the area to be heated, the dimensions of the existing fireplace opening, the desired heating output, and the budget. It is essential to choose an insert that is appropriately sized for the space to ensure optimal heating performance and prevent overheating or underheating. An undersized insert will struggle to heat the room adequately, while an oversized insert may produce excessive heat, leading to discomfort and potential safety concerns.

The first step in selecting an insert is to measure the dimensions of the existing fireplace opening. This includes the width, height, and depth of the firebox. It is crucial to select an insert that fits comfortably within these dimensions while allowing for adequate clearance for proper installation and ventilation. The manufacturer's specifications will typically indicate the minimum fireplace opening dimensions required for each insert model. It is important to consult these specifications carefully before making a purchase.

The heating output of a woodburning fireplace insert is measured in British thermal units (BTUs). The required BTU output will depend on the size and insulation of the area to be heated, as well as the climate. A larger or poorly insulated space will require a higher BTU output than a smaller or well-insulated space. A qualified heating professional can assist in determining the appropriate BTU output for a particular application. Factors such as window size, ceiling height, and the presence of drafts should be considered when calculating heating needs.

In addition to size and heating output, other factors to consider include the type of fuel to be used, the desired features, and the overall aesthetic of the insert. Some inserts are designed to burn only seasoned hardwoods, while others can also burn softwoods or manufactured logs. Features such as blowers, thermostats, and remote controls can enhance the convenience and functionality of the insert. The aesthetic of the insert should complement the existing décor of the room. Options range from traditional cast iron designs to more contemporary steel models.

Finally, budget is an important consideration when selecting a woodburning fireplace insert. The price of inserts can vary widely depending on the brand, size, features, and materials used. It is important to compare prices from different retailers and to factor in the cost of installation. Professional installation is highly recommended to ensure proper operation and safety.

Installation and Maintenance Considerations

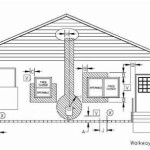

Proper installation is essential for the safe and efficient operation of a woodburning fireplace insert. Installation typically involves several steps, including preparing the fireplace opening, connecting the insert to the chimney, and sealing the insert to the fireplace. It is highly recommended to have a qualified professional install the insert to ensure that all safety requirements are met and that the installation is performed correctly. Improper installation can result in serious safety hazards, such as carbon monoxide poisoning or chimney fires.

Before installing the insert, the fireplace opening must be thoroughly cleaned and inspected. Any debris, soot, or creosote should be removed from the firebox and the chimney. The chimney should also be inspected for cracks, blockages, or other damage. If any damage is found, it should be repaired before installing the insert. A chimney liner is typically required to ensure proper venting and to protect the chimney from corrosion. The liner should be sized appropriately for the insert and installed according to the manufacturer's instructions.

Once the fireplace opening has been prepared, the insert can be placed into the firebox. The insert should be carefully aligned with the chimney flue and connected using a connector pipe. The connector pipe should be properly sealed to prevent leakage of smoke and gases. The insert should also be sealed to the fireplace opening using a non-combustible sealant. This will help to prevent heat loss and to keep smoke from entering the room.

Regular maintenance is essential to ensure the continued safe and efficient operation of a woodburning fireplace insert. This includes cleaning the insert regularly, inspecting the chimney for creosote buildup, and having the chimney professionally inspected and cleaned annually. The frequency of cleaning will depend on the amount of use and the type of fuel being burned. Burning seasoned hardwoods produces less creosote than burning softwoods or unseasoned wood. Creosote is a highly flammable substance that can accumulate in the chimney and cause a chimney fire.

The interior of the insert should be cleaned regularly to remove ash and debris. The glass door should also be cleaned to remove soot and stains. A mild detergent and a soft cloth can be used to clean the glass. Avoid using abrasive cleaners, as they can scratch the glass. The blower, if present, should be cleaned periodically to remove dust and debris. This will help to ensure that the blower operates efficiently and does not overheat.

In addition to regular cleaning, the insert should be inspected periodically for any signs of damage or wear. Check the firebox for cracks or warping. Inspect the door seals to ensure that they are tight and preventing air leakage. If any damage is found, it should be repaired promptly to prevent further damage or safety hazards. A qualified service technician can perform a thorough inspection and make any necessary repairs.

Woodburning fireplace inserts offer a significant improvement over traditional open fireplaces in terms of heating efficiency, emission reduction, and safety. By carefully considering the various factors involved in selecting and installing an insert, homeowners can enjoy the warmth and ambiance of a wood-burning fire while minimizing heat loss and environmental impact. Regular maintenance is crucial to ensure the continued safe and efficient operation of the insert.

Wood Burning Fireplace Inserts 1 Stove Insert Dealer

Wood Burning Fireplace Inserts Insert Installation

Napoleon Epi3 Wood Fireplace Insert Inserts By

Wood Inserts We Love Fire

Why A Wood Burning Fireplace Insert Bethesda Md Service

T25i Timberwolf Wood Fireplace Insert Hearth Stove Patio

Ventis Hei240 Wood Burning Insert

Lopi Premium Wood Fireplace Inserts Custom Hearth Fireplaces And Stoves

.aspx?strip=all)

Cost Of Operating A Wood Insert Cord Calculator Regency

Fireplace Wood Burning Inserts Nashville Tn Ashbusters

Related Posts