Mendota Gas Fireplace Troubleshooting: A Comprehensive Guide

Mendota gas fireplaces are renowned for their quality, efficiency, and aesthetic appeal. However, like any mechanical device, they can occasionally experience issues. This article provides a comprehensive guide to troubleshooting common problems encountered with Mendota gas fireplaces, offering potential solutions and preventative measures.

Before attempting any troubleshooting steps, ensuring the gas supply is turned on and any pilot light safety switches are engaged is critical. Consulting the owner's manual specific to the Mendota fireplace model is also crucial, as procedures can vary. Disconnecting the fireplace from its power source before undertaking any repairs or inspections is a paramount safety precaution.

Pilot Light Issues: Ignition and Flame Stability

A common problem encountered with gas fireplaces is difficulty with the pilot light. The pilot light is a small, continuous flame that ignites the main burner. If the pilot light fails to ignite or remains unstable, the main burner will not function. Several factors can contribute to this issue.

A clogged pilot light orifice is a frequently encountered cause. Dust, debris, or carbon deposits can accumulate in the small opening of the pilot light orifice, restricting the flow of gas. This restriction can weaken or completely extinguish the pilot light. To address this, carefully cleaning the orifice is necessary. The process typically involves shutting off the gas supply, allowing the fireplace to cool completely, and then using a small, stiff wire or a specialized pilot light cleaning tool to gently clear the obstruction. Avoid using any abrasive materials that could damage the orifice.

A faulty thermocouple or thermopile can also disrupt the pilot light operation. The thermocouple is a safety device that senses the heat from the pilot light flame. If the thermocouple is functioning correctly, it generates a small electrical current that keeps the gas valve open, allowing gas to flow to the pilot light. If the thermocouple is defective, it will not generate sufficient current, and the gas valve will close, extinguishing the pilot light. Similarly, a thermopile generates current to operate the main gas valve. A multimeter can be used to test the thermocouple or thermopile output. If the reading is below the manufacturer's specified voltage, the component likely needs replacement.

Drafts can also cause instability in the pilot light flame. Excessive drafts can blow the flame out, particularly in older models or fireplaces located in drafty areas. Checking for and sealing any air leaks around the fireplace is essential. Ensuring proper ventilation in the room, without creating excessive drafts directly impacting the fireplace, is also important. A draft diverter, if applicable to the model, can also be inspected for proper functionality and placement.

A malfunctioning gas regulator can also contribute to pilot light issues. The gas regulator controls the pressure of the gas flowing to the fireplace. If the regulator is not functioning correctly, it can starve the pilot light of gas, causing it to extinguish. This typically requires a qualified gas technician to diagnose and repair or replace the regulator.

Main Burner Problems: Ignition, Flame Appearance, and Odor

After addressing any pilot light issues, problems with the main burner can arise. These issues can manifest as difficulty igniting the main burner, an abnormal flame appearance, or the presence of unusual odors.

Intermittent or delayed ignition of the main burner can often be attributed to a faulty igniter or igniter module. The igniter produces a spark that ignites the gas flowing to the main burner. If the igniter is weak or failing, it may not generate a sufficient spark to ignite the gas reliably. Visually inspecting the igniter for cracks or damage is a first step. Using a multimeter to test the igniter's output is also recommended. If the igniter is not producing a strong, consistent spark, it will need to be replaced. For fireplaces equipped with an igniter module, the module itself may be the source of the problem. Testing and replacing the module, if necessary, should be performed according to the manufacturer's instructions.

The appearance of the flame can provide valuable clues about the fireplace's operational status. A yellow or orange flame, as opposed to a clean blue flame, can indicate incomplete combustion. This incomplete combustion can be caused by insufficient air supply, dirty burner ports, or contaminants in the gas line. Cleaning the burner ports with a soft brush can remove any accumulated debris. Ensuring proper ventilation and checking for any obstructions in the air intake vents is crucial. If the problem persists, a qualified technician should inspect the gas line for contaminants or pressure issues.

Unusual odors emanating from the fireplace can signal potential problems requiring immediate attention. A strong smell of gas indicates a possible gas leak, necessitating immediate evacuation and contacting the gas company or a qualified technician. Other odors, such as a burning smell, can indicate dust or debris burning off the fireplace's components. This can be resolved by thoroughly cleaning the fireplace, paying particular attention to areas where dust tends to accumulate, such as around the burner and logs. If the odor persists after cleaning, it may indicate a more serious problem, such as a damaged component, requiring professional inspection.

Flame height issues can occur due to a regulator malfunction or incorrect gas pressure. If the flames are too low, the fireplace may not provide adequate heat. If the flames are too high, it could be a safety hazard. A manometer is used to test the gas pressure, and the reading should be within the manufacturer's specified range. Adjustment or replacement of the gas regulator should only be performed by a certified technician.

Control System Malfunctions: Remote Control, Thermostat, and Wiring

Modern gas fireplaces often incorporate sophisticated control systems, including remote controls, thermostats, and electronic ignition systems. Malfunctions in these systems can prevent the fireplace from operating correctly.

If the remote control is not functioning, the first step is to check the batteries. Replacing the batteries with fresh ones is often the solution. If the problem persists, ensuring the remote control is properly paired with the fireplace receiver is necessary. The pairing procedure varies depending on the fireplace model and is typically outlined in the owner's manual. If the remote control continues to fail, the receiver unit in the fireplace may be faulty and require replacement.

Thermostat issues can prevent the fireplace from maintaining a consistent temperature. If the thermostat is not accurately sensing the room temperature, the fireplace may cycle on and off frequently or fail to turn on at all. Ensuring the thermostat is located away from drafts and direct sunlight is crucial. The thermostat itself may be faulty and require calibration or replacement. Digital thermostats may require reprogramming or resetting according to the manufacturer's instructions.

Wiring problems can also cause control system malfunctions. Loose or corroded wiring connections can disrupt the flow of electricity, preventing the fireplace from operating correctly. Visually inspecting all wiring connections for damage or corrosion is essential. Tightening any loose connections and cleaning any corroded connections with a wire brush can often resolve the issue. If the wiring is significantly damaged, it should be replaced by a qualified electrician.

A faulty control module, whether it's for the ignition, flame control, or other functions, can impede the fireplace's operation. Identifying a precise malfunction requires diagnostic procedures outlined in the service manual. This often involves voltage and continuity testing to isolate the defective components. Replacing control modules should be done according to the specific manufacturer's instructions.

Regular maintenance, including cleaning the burner assembly, inspecting the venting system, and checking the gas connections, can prevent many of these problems from occurring in the first place. Scheduling annual professional inspections and maintenance can ensure the safe and efficient operation of the Mendota gas fireplace for years to come. Always prioritizing safety and consulting with qualified professionals when dealing with gas appliances is essential. Attempting repairs beyond one's expertise can be hazardous and should be avoided.

Remote Control Walk Through On Mendota And Fireplace X Ipi Systems 1 2

Remote Control Walk Through On Mendota And Fireplace X Ipi Systems 1 2

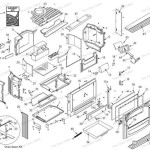

Dxv 45 Manual Mendota

Mendota Gas Fireplace Model Dxv45 Deep Timber 3

The Main Burner Flame Will Not Come On Or Stay Www Mygasfireplacerepair Com

Heat Glo Gas Fireplace Troubleshooting

Mendota Traditional Gas Fireplaces Window Fireplace

Mendota Fv44i Gas Fireplace Insert Bowden S Fireside

Gas Fireplace Troubleshooting Tips And Tricks

Mendota Natural Gas Pilot Assembly 05 04 00035 Fire Parts Ca

Related Posts