Understanding Fireplace Exhaust Pipes: A Comprehensive Guide

Fireplace exhaust pipes, also known as chimney liners, vent pipes, or flue liners, are critical components of any fireplace system. They serve as the conduit for safely venting combustion byproducts, such as smoke, carbon monoxide, and other gases, away from the living space and into the atmosphere. Selecting, installing, and maintaining the correct type of exhaust pipe is essential for ensuring the safety and efficiency of the fireplace.

The primary function of a fireplace exhaust pipe is to create a secure and reliable pathway for combustion gases. Without a properly functioning exhaust system, these hazardous byproducts can leak into the home, posing serious health risks, including carbon monoxide poisoning. Furthermore, a damaged or improperly installed exhaust pipe can contribute to chimney fires and structural damage.

Key Point 1: Types of Fireplace Exhaust Pipes

Various types of fireplace exhaust pipes are available, each designed for specific fuel types and fireplace configurations. The selection process should carefully consider the type of heating appliance and any local building codes.

Clay Tile Liners: Clay tile liners are one of the oldest and most traditional types of chimney liners. They are typically constructed from sections of fireclay or terracotta and are mortared together inside the chimney. While relatively inexpensive, clay tile liners are prone to cracking and deterioration over time, especially when exposed to drastic temperature fluctuations or acidic condensation from burning certain fuels.

Clay tile liners are generally suitable for wood-burning fireplaces, but their performance can be compromised if they are not properly maintained or if they experience excessive moisture infiltration. Inspections are crucial to identify any cracks or gaps that could allow gases to escape.

Metal Chimney Liners: Metal chimney liners are a modern and often preferred alternative to clay tile liners. They are typically made from stainless steel or aluminum and are available in both rigid and flexible forms. Stainless steel liners are highly durable and resistant to corrosion, making them suitable for a wide range of fuel types, including wood, gas, and oil.

Flexible metal liners are particularly useful for relining existing chimneys that have irregular shapes or offsets. Rigid liners provide a more robust and structurally sound solution for new construction or when replacing severely damaged clay tile liners. Metal liners offer superior performance and longevity compared to clay tile options when properly installed and maintained.

Cast-in-Place Liners: Cast-in-place liners involve pouring a heat-resistant concrete mixture into the existing chimney flue. This creates a seamless, airtight lining that provides excellent insulation and structural support. Cast-in-place liners are a good option for restoring deteriorated chimneys or for improving the efficiency of older fireplaces. The process typically requires professional installation and can be more expensive than other lining methods, but the resulting liner is highly durable and long-lasting.

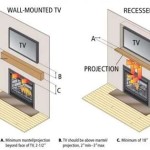

Vent Pipes for Gas Fireplaces: Gas fireplaces often use specialized vent pipes designed specifically for gas combustion byproducts. These vent pipes are typically made from aluminum or stainless steel and are available in various configurations, including direct vent, B-vent, and C-vent systems. Direct vent systems draw combustion air from outside the home and vent exhaust gases directly outdoors, eliminating the need for a traditional chimney.

B-vent systems rely on natural draft to vent exhaust gases, while C-vent systems are designed for use with specific types of gas appliances. It is crucial to use the correct type of vent pipe specified by the manufacturer of the gas fireplace to ensure safe and efficient operation.

Key Point 2: Installation and Safety Considerations

Proper installation of a fireplace exhaust pipe is paramount to ensure the safety and efficiency of the fireplace system. Installation should adhere to manufacturer’s instructions and local building codes. Improper installation can lead to dangerous gas leaks, chimney fires, and structural damage.

Professional Installation: While some homeowners may be tempted to install a fireplace exhaust pipe themselves, it is generally recommended to hire a qualified professional. Certified chimney sweeps or HVAC technicians have the expertise and experience to ensure that the installation is done correctly and safely. They can also identify any potential issues with the chimney structure or fireplace system.

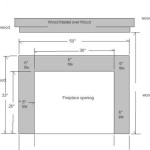

Sizing the Exhaust Pipe: The diameter of the exhaust pipe must be properly sized to match the fireplace and the chimney flue. An undersized pipe can restrict airflow and lead to incomplete combustion, resulting in increased creosote buildup and a higher risk of chimney fires. An oversized pipe can cause the exhaust gases to cool too quickly, leading to condensation and corrosion.

Insulation: Insulating the exhaust pipe can improve its efficiency by reducing heat loss and preventing condensation. Insulation also helps to maintain a consistent flue temperature, which promotes better draft and reduces the risk of creosote formation. Metal chimney liners are often wrapped with an insulating blanket or poured with a vermiculite/cement mixture to provide thermal protection.

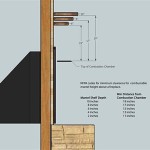

Clearances to Combustibles: Maintaining proper clearances between the exhaust pipe and any combustible materials, such as wood framing or insulation, is crucial to prevent fires. Building codes typically specify the minimum clearance requirements, which vary depending on the type of exhaust pipe and the surrounding materials. Failure to maintain adequate clearances can result in a fire hazard.

Inspections and Permits: Many municipalities require inspections and permits for fireplace exhaust pipe installations. Obtaining the necessary permits ensures that the installation meets local building codes and that the fireplace system is safe to operate. Inspections are typically performed by local building officials or certified inspectors.

Key Point 3: Maintenance and Inspection

Regular maintenance and inspection of the fireplace exhaust pipe are essential for ensuring its continued safety and performance. Neglecting maintenance can lead to a buildup of creosote, blockages, and structural damage, increasing the risk of chimney fires and other hazards.

Creosote Removal: Creosote is a highly flammable byproduct of wood combustion that accumulates inside the exhaust pipe. Regular chimney sweeping is necessary to remove creosote buildup and prevent chimney fires. The frequency of chimney sweeping depends on the type of wood burned, the frequency of fireplace use, and the efficiency of the fireplace system. It is generally recommended to have the chimney swept at least once a year, or more often if heavy creosote buildup is observed.

Visual Inspections: Homeowners should visually inspect the fireplace exhaust pipe and chimney structure regularly for any signs of damage, such as cracks, gaps, or deterioration. Pay close attention to the area around the chimney crown, flue liner, and chimney base.

Professional Inspections: In addition to regular visual inspections by homeowners, it is recommended to have a professional chimney inspection performed at least once a year. Certified chimney sweeps can conduct thorough inspections using specialized equipment, such as video cameras, to detect hidden damage or potential problems. They can also provide recommendations for repairs or maintenance.

Addressing Moisture Issues: Moisture can be a significant contributor to chimney deterioration. Condensation from burning certain fuels, rainwater infiltration, and groundwater seepage can all damage the chimney structure and exhaust pipe. Addressing any moisture issues promptly is crucial to prevent further damage. This may involve repairing leaks, installing a chimney cap, or improving the chimney's drainage.

Repairing or Replacing Damaged Liners: If the fireplace exhaust pipe is found to be damaged, it should be repaired or replaced as soon as possible. Damaged liners can allow dangerous gases to leak into the home and can compromise the structural integrity of the chimney. Depending on the extent of the damage, repairs may involve patching cracks, applying a sealant, or installing a new liner.

In summary, understanding the different types of fireplace exhaust pipes, adhering to proper installation practices, and implementing a regular maintenance and inspection program are critical for ensuring the safety and efficiency of any fireplace system. By taking these steps, homeowners can protect their families from the dangers of carbon monoxide poisoning, chimney fires, and structural damage.

The selection of the appropriate exhaust pipe is based on several factors. This include the type of fuel used, the design of the fireplace and the chimney structure. Consulting with a qualified professional can provide valuable guidance in determining the best solution for individual needs.

Regular maintenance extends the lifespan of the exhaust pipe and the overall chimney system. Consistent cleaning and inspections prevent costly repairs in the future. Address any issues promptly to maintain a safe and efficient fireplace.

Gas Fireplace Venting Explained Heat Glo

Understanding How Direct Vent Works Heat Glo

Gas Fireplace Venting Explained Heat Glo

What Are The Best Ways To Vent A Gas Fireplace Zoroast

Benefits Of Direct Vent Fireplaces

Vented Vs B Vent Direct Free Dixie S

Chimney And Venting Pipe Guide Fireplaces Direct Learning Center

The Ultimate Guide To 5 Types Of Chimney Pipe By Pros

Gas Fireplace Venting Friendly Fires

Venting A Gas Fireplace Through Existing Chimney Design Inserts

Related Posts