Selecting and Installing the Right Fireplace Pipe Kit

A fireplace is a valued addition to any home, providing warmth, ambiance, and a focal point for gatherings. However, a functional fireplace requires a safe and properly installed venting system. The fireplace pipe kit provides the necessary components to safely exhaust combustion byproducts from the fireplace, safeguarding the home and its occupants from hazardous gases like carbon monoxide. This article aims to provide a comprehensive overview of fireplace pipe kits, covering considerations for selection, the different types available, and the essential steps involved in installation.

Understanding the components of a fireplace pipe kit is crucial for a successful installation. Typically, a kit will include several sections of pipe, often made of double-wall or triple-wall construction for enhanced insulation and safety. These sections connect to form the vertical chimney flue. The kit often contains a starting collar, which connects the stove or fireplace to the pipe system. Support brackets, flashing for roof penetration, a rain cap to prevent water intrusion, and possibly a spark arrestor to prevent embers from escaping are also generally included.

Selecting the right fireplace pipe kit requires careful consideration of several factors. Compatibility with the fireplace, the height of the chimney required, and local building codes are paramount. A mismatch can lead to unsafe operation, code violations, and potential fire hazards.

Key Point 1: Compatibility and Sizing

The most crucial aspect of selecting a fireplace pipe kit is ensuring compatibility with the specific fireplace or wood stove being used. Fireplaces are designed to work with specific flue sizes, and using an incorrect size can drastically impair performance and safety. An undersized flue can lead to smoke backdrafting into the room, while an oversized flue can reduce the draft and increase the risk of creosote buildup. Creosote, a highly flammable byproduct of wood combustion, poses a significant fire hazard if allowed to accumulate in the chimney.

The manufacturer of the fireplace or stove will specify the required flue diameter, typically in inches. This information is usually found in the owner's manual or on a label attached to the appliance. When selecting a pipe kit, the diameter of the pipes must precisely match this specification. Deviating from the recommended size is not advisable and can void warranties. Beyond the diameter, ensure the pipe's material is approved for the type of fuel being burned. Certain pipe materials are better suited for wood, gas, or pellet-burning appliances.

Furthermore, consider the "stove pipe" versus "chimney pipe" distinction. Stove pipe, typically single-wall, is used only for connecting the appliance to the wall thimble or to the chimney. It is not designed to pass through walls or ceilings due to its lack of insulation and high surface temperature. Chimney pipe, on the other hand, is designed for vertical runs through the building, offering the necessary insulation and fire protection.

Key Point 2: Types of Fireplace Pipe Kits

Fireplace pipe kits are not created equal. Different types offer varying levels of insulation, construction materials, and intended applications. Understanding the nuances of each type is crucial for making an informed decision.

Single-wall stove pipe is the most basic type, as previously mentioned. It's typically made of black steel and is used for short runs connecting the appliance to the chimney system. It's the least expensive option but provides no insulation. Its primary purpose is aesthetic and functional within the immediate vicinity of the appliance. Due to the lack of insulation, it is not recommended for passing through walls or ceilings.

Double-wall stove pipe offers improved safety compared to single-wall pipe. The double-wall construction provides a layer of air insulation between the inner and outer pipes, reducing the surface temperature of the outer pipe. This makes it safer to touch and reduces the risk of igniting nearby combustible materials. While an improvement over single-wall, it is still not recommended for chimney systems running through walls or ceilings.

Double-wall insulated chimney pipe is designed for vertical chimney runs that pass through walls and ceilings. It features two layers of metal with insulation, often fiberglass or ceramic fiber, packed between them. This insulation dramatically reduces the surface temperature of the outer pipe and prevents heat transfer to surrounding materials. Double-wall insulated pipe is the industry standard for safe and efficient chimney systems. It is crucial for meeting building codes and preventing fire hazards.

Triple-wall chimney pipe takes insulation a step further. It features three layers of metal with two layers of insulation. This provides the highest level of protection and is often used in applications where clearances to combustibles are extremely limited. While more expensive than double-wall, triple-wall pipe offers superior safety and peace of mind.

Flexible chimney liners, often made of stainless steel, are used to reline existing masonry chimneys. They are particularly useful when the original chimney is damaged or the flue size is incompatible with the new fireplace or stove. Flexible liners are easy to install and can significantly improve the safety and efficiency of an existing chimney.

Key Point 3: Installation Considerations and Safety

Installing a fireplace pipe kit is a complex task that requires careful planning, attention to detail, and adherence to safety precautions. While it is possible to install a kit yourself, it is generally recommended to hire a qualified professional. Improper installation can lead to serious safety hazards, including carbon monoxide poisoning and house fires.

Before beginning any installation, carefully review the manufacturer's instructions and local building codes. These documents provide essential information on proper installation techniques, required clearances, and safety guidelines. Failure to comply with these regulations can result in code violations and potential safety risks.

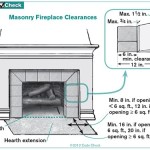

Maintaining proper clearances to combustible materials is paramount. Combustible materials, such as wood framing, drywall, and insulation, can ignite if they come into contact with hot chimney pipes. The manufacturer's instructions will specify the minimum clearances required for each section of pipe. These clearances must be strictly adhered to. Often, heat shields or other protective measures are required to reduce the risk of fire.

When installing the pipe, ensure that each section is securely connected. Use the appropriate locking mechanisms or fasteners as specified by the manufacturer. Loose or improperly connected pipes can leak dangerous gases into the home.

Properly sealing the roof penetration is also critical. Flashing is used to create a watertight seal around the chimney pipe where it passes through the roof. This prevents water from leaking into the home and damaging the structure. The flashing should be installed according to the manufacturer's instructions and sealed with a high-quality sealant.

After the installation is complete, have the system inspected by a qualified professional. A certified chimney sweep can verify that the installation meets all applicable codes and regulations and that the system is operating safely and efficiently. Furthermore, regular chimney inspections and cleaning are crucial for maintaining the safety and efficiency of the fireplace system. Creosote buildup should be removed regularly to prevent chimney fires. Animals can also build nests in the chimney, which can block the flue and create a dangerous situation.

Safety should always be the top priority when dealing with fireplaces and chimney systems. Carbon monoxide detectors should be installed in the home to provide early warning of potential leaks. These detectors should be tested regularly to ensure they are functioning properly.

By understanding the different types of fireplace pipe kits, the importance of compatibility and sizing, and the essential steps involved in installation, homeowners can make informed decisions and ensure the safe and efficient operation of their fireplaces.

Friendly Fires Wood Stove 6 Chimney Kit Up Out

Duratech 6 Inch Round Ceiling Support Chimney Kit

Through The Wall Kit For 6 Inner Diameter Chimney Pipe With Flat Top Cap

Flat Ceiling Kit For Selkirk Metalbestos Chimney Pipe Systems Rockford

Ceiling Support Kit Components

Comfortbilt Piping Kit Black Matte

Friendly Fires Wood Stove 6 Chimney Kit Flat Ceiling

8 Duraplus Thru The Wall Kit Dp830

Harvia Chimney Kit

Through Wall Chimney Pipe Kit Class A Insluated Rockford

Related Posts