Insulating a Fireplace Insert: Enhancing Efficiency and Safety

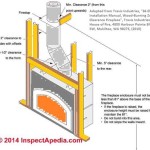

Fireplace inserts are effective heating appliances designed to be installed within existing fireplaces. They offer a more efficient and controlled source of heat compared to traditional open hearth fireplaces. However, even with an insert, a significant amount of heat can be lost into the existing chimney cavity if proper insulation is not implemented. This heat loss reduces the overall efficiency of the insert and can create drafts. Effectively insulating a fireplace insert is a crucial step in maximizing its performance and ensuring a safe and comfortable home environment.

The primary goal of insulating around a fireplace insert is to minimize heat escaping up the chimney and direct it into the living space. Uninsulated spaces around the insert allow heat to rise and dissipate, rendering the insert less effective. Furthermore, a cold chimney can create downdrafts, drawing cold air into the room when the insert is not in use. Properly insulating mitigates these issues, leading to lower heating bills and a more consistent temperature throughout the house.

Selecting the appropriate insulation material is essential for safety and performance. The material must be non-combustible, heat-resistant, and durable enough to withstand the fluctuating temperatures within the chimney. Several suitable options exist, each with its own set of advantages and disadvantages.

Choosing the Right Insulation Material

Several factors contribute to the selection of the optimal insulation material for a fireplace insert. Considerations include the temperature rating of the material, its ease of installation, cost-effectiveness, and its long-term durability.

Mineral Wool Insulation: Mineral wool, also known as rock wool, is a commonly used insulation material for fireplace inserts due to its high temperature resistance and fireproofing properties. It is made from molten rock, slag, or glass, spun into fibers. It is non-combustible and can withstand temperatures exceeding 1000 degrees Fahrenheit. Mineral wool is typically available in batts or rolls, allowing for relatively easy installation within the chimney cavity. It effectively fills voids and provides excellent thermal insulation.

Ceramic Fiber Insulation: Ceramic fiber insulation offers superior heat resistance compared to mineral wool, often capable of withstanding temperatures up to 2300 degrees Fahrenheit. This material is lightweight and flexible, making it suitable for filling irregular spaces around the insert. Its primary drawback is cost, as ceramic fiber insulation is generally more expensive than mineral wool. It is often used in high-heat applications or when space is limited.

Vermiculite Insulation: Vermiculite is a mineral that expands when heated, creating a lightweight, fire-resistant insulation material. It is often used in loose-fill form, allowing it to conform to complex shapes within the chimney cavity. Vermiculite is less effective at insulating compared to mineral wool or ceramic fiber, but it is a cost-effective option for filling large voids and preventing drafts. It is important to ensure the vermiculite used is asbestos-free.

Preparing for the Insulation Process

Before beginning the insulation process, a thorough inspection of the chimney and fireplace insert is crucial. This includes checking for any signs of damage, such as cracks in the chimney liner or deterioration of existing insulation. Any necessary repairs should be completed before proceeding with the insulation.

Safety Precautions: Prioritizing safety is paramount during the insulation process. Wear appropriate personal protective equipment (PPE), including gloves, a dust mask, and eye protection, to prevent skin irritation and respiratory problems from handling insulation materials. Ensure adequate ventilation in the work area to minimize exposure to dust and fibers. Disconnect the fireplace insert from any power source before starting work.

Cleaning and Preparation: Thoroughly clean the chimney and surrounding area to remove any debris, soot, or creosote buildup. This ensures proper adhesion of the insulation and prevents potential fire hazards. Use a chimney brush and vacuum to remove loose particles. Inspect the chimney flue for any obstructions and remove them if necessary.

Proper Installation Techniques

The method of installing insulation around a fireplace insert depends on the type of insulation material chosen and the configuration of the fireplace. Proper installation is crucial to ensure maximum efficiency and safety.

Mineral Wool Installation: When using mineral wool batts or rolls, cut them to fit the spaces around the insert, ensuring a snug fit. Avoid compressing the insulation excessively, as this can reduce its effectiveness. Pack the mineral wool tightly around the insert, paying particular attention to gaps and crevices. Use heat-resistant tape to secure the insulation in place if necessary.

Ceramic Fiber Installation: Ceramic fiber insulation can be cut and shaped to fit the contours of the chimney cavity. Wear gloves when handling ceramic fiber, as it can be irritating to the skin. Apply the insulation in layers, ensuring each layer is firmly packed. Seal any seams or gaps with high-temperature sealant to prevent heat loss.

Vermiculite Installation: Pour vermiculite loose-fill insulation into the chimney cavity, filling the spaces around the insert. Use a long-handled scoop or shovel to reach areas that are difficult to access. Ensure the vermiculite completely fills the voids, but avoid overfilling, which can restrict airflow. Periodically check the level of the vermiculite and add more as needed as it settles.

After installing the insulation, carefully inspect the work to ensure there are no gaps or exposed areas. Verify that the insulation is not obstructing any vents or access panels on the fireplace insert. Conduct a test burn to ensure the insert is operating correctly and that there are no unusual odors or smoke coming from the chimney. Monitor the surrounding areas for excessive heat buildup during the test burn.

Electric Fireplace Insulation An Ultimate Guide Inserts Guy

Insulation Around A Fireplace Insert Hearth Com Forums Home

Finally Got Around To Insulating My Fireplace Hearth Com Forums Home

Walls Behind Fireplaces Building America Solution Center

Finally Got Around To Insulating My Fireplace Hearth Com Forums Home

Chimney Liners Usa Fireplace Insert Venting Information

Walls Behind Fireplaces Building America Solution Center

How To Insulate Prefab Chimney Interior Wall Greenbuildingadvisor

Finally Got Around To Insulating My Fireplace Page 2 Hearth Com Forums Home

How To Insulate An Electric Fireplace Process Tools Insulation Types Inserts Guy

Related Posts