```html

Large Fireplace Insert: A Comprehensive Guide

A large fireplace insert represents a significant upgrade to an existing masonry fireplace, offering improved heating efficiency, enhanced aesthetics, and greater operational convenience. These inserts are designed to fit within the opening of a traditionally built fireplace, transforming it from a typically inefficient, open-hearth system into a closed-combustion heating appliance. Understanding the characteristics, benefits, and considerations involved in selecting and installing a large fireplace insert is crucial for homeowners seeking to maximize the value of their fireplace.

The term "large" as applied to fireplace inserts is relative and depends on the size of the existing fireplace opening. Generally, large inserts are designed to accommodate fireplace openings with widths exceeding 30 inches and heights exceeding 24 inches. These larger models typically boast higher heat output capabilities, measured in British Thermal Units (BTUs), allowing them to effectively heat larger living spaces or even entire homes in some cases.

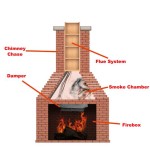

The primary function of a fireplace insert is to improve the efficiency of wood or gas burning. Open fireplaces are notoriously inefficient, with much of the heat generated escaping up the chimney. This is due to the natural draw of air, which pulls warm air from the room and exhausts it along with the combustion gases. Fireplace inserts, by contrast, create a sealed combustion chamber, significantly reducing heat loss and maximizing the transfer of heat into the living space. Many modern inserts can achieve heating efficiencies of 70% or higher, a stark contrast to the 10-20% efficiency often associated with traditional open fireplaces.

Beyond efficiency, large fireplace inserts offer improved safety features. The closed combustion chamber prevents the escape of sparks and embers, reducing the risk of house fires. Additionally, many inserts feature glass doors that provide a clear view of the fire while preventing direct contact with the flames. These doors often incorporate air wash systems, which circulate air across the glass to keep it clean and clear of soot buildup.

The installation of a large fireplace insert requires careful planning and professional execution. The insert must be properly sized to fit the existing fireplace opening, and the chimney must be inspected and, if necessary, relined to ensure proper venting. Improper installation can lead to safety hazards, including carbon monoxide poisoning and chimney fires. Local building codes and regulations must be adhered to throughout the installation process.

Key Point 1: Fuel Options and Heating Capacity

Large fireplace inserts are available in a variety of fuel options, including wood, gas (natural gas or propane), and pellet-burning models. Each fuel type has its own advantages and disadvantages in terms of heating capacity, cost, environmental impact, and convenience. Wood-burning inserts offer a traditional aesthetic and can provide significant heat output, but they require manual loading of wood and regular ash removal. Gas inserts offer greater convenience with on-demand ignition and thermostat control, but they are dependent on a gas supply and may have higher operating costs compared to wood. Pellet inserts offer a balance of convenience and efficiency, using compressed wood pellets as fuel, which are typically more efficient than traditional firewood and produce less smoke. The choice of fuel depends on individual preferences, local fuel availability, and desired levels of convenience and heating output.

The heating capacity of a large fireplace insert is typically measured in BTUs. A higher BTU rating indicates a greater ability to heat a larger space. When selecting an insert, it is important to consider the size of the area to be heated, the insulation levels of the home, and the climate. A properly sized insert will provide adequate heat without overheating the room. Manufacturers typically provide guidance on recommended BTU ratings based on square footage, allowing homeowners to make informed decisions.

Furthermore, the heat distribution method can influence the effectiveness of a fireplace insert. Some inserts rely on natural convection to circulate heat, while others incorporate blowers to force warm air into the room. Blower systems can significantly improve heat distribution, especially in larger spaces or homes with multiple rooms. However, blowers may add noise and require electricity to operate.

Key Point 2: Chimney and Venting Considerations

The chimney is a critical component of any fireplace insert system, responsible for safely venting combustion gases to the outside. A properly functioning chimney is essential for preventing carbon monoxide poisoning and chimney fires. Before installing a large fireplace insert, the chimney must be thoroughly inspected for any damage or obstructions. Cracks, leaks, or blockages can impair the chimney's ability to vent properly and pose serious safety risks.

In many cases, the existing chimney will need to be relined with a stainless steel liner to ensure compatibility with the fireplace insert. This is particularly important when converting from an open fireplace to a closed-combustion insert, as the insert will produce higher flue gas temperatures and different types of combustion byproducts. A stainless steel liner provides a smooth, durable, and corrosion-resistant pathway for the flue gases, protecting the masonry chimney from damage and preventing leaks. The liner must be properly sized to match the insert's flue outlet and installed according to manufacturer's instructions and local building codes.

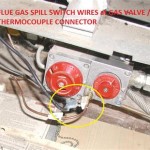

The venting requirements for gas and pellet inserts differ from those of wood-burning inserts. Gas inserts typically require a direct-vent system, which draws combustion air from outside and exhausts the flue gases directly through a dedicated vent pipe. Pellet inserts may require a special pellet vent pipe, which is designed to withstand the corrosive effects of pellet combustion byproducts. It is important to consult with a qualified installer to determine the appropriate venting system for the chosen fireplace insert.

Key Point 3: Installation and Maintenance

The installation of a large fireplace insert is not a do-it-yourself project. It requires specialized knowledge, skills, and tools to ensure proper and safe operation. A qualified installer will be familiar with local building codes and regulations, as well as the specific requirements of the chosen fireplace insert. The installer will also be able to assess the condition of the chimney and recommend any necessary repairs or upgrades.

The installation process typically involves preparing the fireplace opening, installing the chimney liner (if necessary), connecting the insert to the venting system, and testing the operation of the insert. The installer will also provide instructions on how to operate and maintain the insert properly. It is important to retain all documentation related to the installation, including the manufacturer's instructions and the installer's contact information.

Regular maintenance is essential for ensuring the long-term performance and safety of a large fireplace insert. This typically includes cleaning the glass door, inspecting the chimney for any buildup of creosote or soot, and checking the venting system for any obstructions. Wood-burning inserts require periodic ash removal, while gas inserts may require cleaning of the burner and pilot light. Manufacturers typically provide detailed maintenance schedules in their owner's manuals. It is recommended to have the fireplace insert and chimney professionally inspected and cleaned at least once a year, especially for wood-burning models. This will help to prevent chimney fires and ensure that the insert is operating safely and efficiently.

In addition to routine maintenance, it is important to address any issues promptly. If the fireplace insert is not operating properly, such as producing excessive smoke, making unusual noises, or not heating properly, it should be inspected by a qualified technician. Ignoring these problems can lead to more serious damage and potentially dangerous situations. Following the manufacturer's recommendations for operation and maintenance will help to prolong the life of the fireplace insert and ensure its safe and efficient operation for many years to come.

```

Large Flush Wood Rectangular Nexgen Fyre Made In America Fireplace Xtrordinair

Large Flush Wood Arched Nexgen Fyre Made In America Fireplace Xtrordinair

Fireplace X Large Flush Wood Nexgen Fyre Insert Olde Towne Chimney

Ventis Hei240 Wood Fireplace Insert Mace Energy Supply

Wood Inserts Fireplace And Stove The Hearth Doctor Inc

Wood Fireplace Inserts Made In America Xtrordinair

Enviro E44 Large Gas Insert Colorado Hearth And Home

Large Flush Wood Nexgen Fyre Arch Steel Fireplace Inserts Made In Usa Lopi Stoves

Lri6e Large Traditional Gas Fireplace Insert Regency

Rushmore 30 Direct Vent Fireplace Insert Fine S Gas