Gas Fireplace Insert Installation: A Comprehensive Guide

Gas fireplace insert installation is a significant home improvement project that can transform an inefficient, open-hearth fireplace into a reliable and aesthetically pleasing heating source. This process involves several critical steps, demanding meticulous planning, precise execution, and adherence to safety regulations. Understanding these steps and their implications is vital for homeowners considering this upgrade.

A gas fireplace insert is essentially a self-contained heating unit designed to fit directly into an existing fireplace opening. Unlike traditional wood-burning fireplaces, gas inserts offer increased efficiency, ease of use, and reduced emissions. They utilize either natural gas or propane as fuel and vent exhaust gases through a liner installed within the existing chimney. This article provides a detailed overview of gas fireplace insert installation, covering essential considerations, preparatory steps, the installation procedure itself, and post-installation checks.

Assessing Existing Fireplace and Chimney Condition

The initial and arguably most crucial step in gas fireplace insert installation is a thorough assessment of the existing fireplace and chimney. This involves a professional inspection to identify any structural deficiencies, blockages, or potential hazards. The condition of the chimney is particularly significant, as it will house the venting system for the gas insert. Cracks, loose bricks, or deteriorated mortar joints can compromise the chimney's integrity and pose a safety risk.

A chimney sweep should clean the flue to remove creosote buildup and other debris, ensuring a clear and unobstructed path for the new vent liner. If the existing chimney is damaged beyond repair, chimney restoration or replacement may be necessary before proceeding with the insert installation. Furthermore, the dimensions of the fireplace opening must be accurately measured to ensure the selected gas insert fits properly. Insufficient space can lead to installation difficulties and potential safety issues.

Beyond the physical structure, the presence of combustible materials near the fireplace opening should be evaluated. Mantels, surrounds, and adjacent walls must comply with the manufacturer's clearance requirements for the specific gas insert being installed. Non-combustible materials may need to be installed to provide adequate thermal protection and prevent fire hazards. Local building codes also dictate specific requirements for fireplace and chimney construction, which must be adhered to throughout the installation process.

Selecting the Appropriate Gas Fireplace Insert

Choosing the right gas fireplace insert is paramount to achieving the desired heating performance and aesthetic appeal. Several factors influence this decision, including the size of the area to be heated, the available fuel source (natural gas or propane), the desired heat output (measured in BTUs), and the visual style of the insert. Gas inserts are available in a wide range of styles, from contemporary designs with linear flames to traditional models with realistic log sets.

The BTU output of the insert should be appropriately sized for the room. An insert that is too small may struggle to heat the space effectively, while an oversized insert may produce uncomfortable levels of heat or cycle on and off frequently. Consulting with a qualified HVAC professional can help determine the optimal BTU rating for the specific heating needs. The available fuel source also dictates the type of gas insert that can be used. Natural gas inserts require a natural gas supply line, while propane inserts require a propane tank and regulator.

Efficiency ratings are another important consideration. Gas inserts are rated based on their Annual Fuel Utilization Efficiency (AFUE), which indicates the percentage of fuel converted into usable heat. Higher AFUE ratings translate to lower fuel consumption and reduced heating costs. In addition to performance characteristics, the visual aesthetics of the insert should complement the existing decor of the room. Options include various log set arrangements, flame patterns, and facing materials. It's also necessary to check for any applicable rebates or incentives offered by local utility companies or government agencies for installing energy-efficient gas fireplaces.

The Gas Fireplace Insert Installation Procedure

The actual installation of a gas fireplace insert is a multi-stage process that requires precision and attention to detail. It is strongly recommended that a qualified and licensed gas appliance installer perform the installation to ensure safety and compliance with building codes. The first step typically involves preparing the fireplace opening by removing any existing fireplace components, such as grates, screens, and dampers.

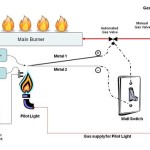

Next, the vent liner is installed within the existing chimney flue. This liner is typically made of flexible stainless steel and is designed to withstand the high temperatures produced by the gas insert. The liner must be properly sized and installed according to the manufacturer's instructions. It extends from the flue collar on the gas insert all the way to the top of the chimney, providing a sealed and safe pathway for exhaust gases. A top plate or chimney cap is installed to prevent rain, snow, and debris from entering the chimney.

After installing the vent liner, the gas insert is carefully positioned inside the fireplace opening. It is typically secured in place with screws or brackets. The gas supply line is then connected to the gas insert, and all connections are leak-tested to ensure there are no gas leaks. This step is crucial for safety and should be performed with a gas leak detector. Electrical connections are also made to power the insert's blower fan, ignition system, and any other electronic components. Once all connections are secure, the insert is tested to verify proper operation. This includes checking the ignition system, flame height, blower fan, and thermostat settings. The installation is completed by installing the decorative facing around the insert to conceal the edges and create a finished appearance.

Venting Considerations and Installation

Proper venting is critical for the safe and efficient operation of a gas fireplace insert. The venting system serves to expel combustion byproducts, such as carbon dioxide and water vapor, from the home. Improper venting can lead to carbon monoxide poisoning, a potentially deadly hazard. Therefore, selecting and installing the correct vent liner is of utmost importance.

Gas inserts typically utilize either direct vent or B-vent systems. Direct vent systems draw combustion air from outside the home and vent exhaust gases directly to the outside. This type of system is more efficient and less prone to backdrafting than B-vent systems. B-vent systems, on the other hand, draw combustion air from inside the home and vent exhaust gases into the chimney. B-vent systems are generally less expensive but require careful consideration of the home's ventilation. The vent liner must be compatible with the type of gas insert being installed and must be sized according to the manufacturer's specifications.

During installation, the vent liner must be properly sealed at both the top and bottom to prevent leaks. The liner should also be insulated to minimize heat loss and prevent condensation. The chimney cap should be designed to prevent rain and debris from entering the chimney while allowing exhaust gases to escape freely. Regular inspection of the venting system is recommended to ensure it remains in good working order. Any signs of damage or deterioration should be addressed promptly to prevent safety hazards.

Gas Line Connection and Safety Measures

Connecting the gas line to the gas fireplace insert requires specialized knowledge and skills. It is essential to hire a qualified gas fitter to perform this task. The gas supply line must be properly sized to provide adequate gas flow to the insert. An undersized gas line can result in poor performance, while an oversized gas line can be a safety hazard.

Before connecting the gas line, the gas supply should be turned off at the main shut-off valve. The gas line should be cleaned and purged of any debris or air. A gas shut-off valve should be installed near the gas insert to allow for easy shut-off in case of emergency. All gas connections should be made with approved fittings and sealant. After making the connections, a gas leak test should be performed using a gas leak detector. This test is crucial to ensure there are no gas leaks, which can be extremely dangerous.

Carbon monoxide detectors should be installed in the vicinity of the gas fireplace insert to provide early warning of any carbon monoxide leaks. These detectors should be tested regularly to ensure they are functioning properly. It is also important to educate all household members about the dangers of carbon monoxide poisoning and the symptoms to watch out for. Regular maintenance of the gas fireplace insert, including cleaning and inspection, is essential for safe and reliable operation.

Post-Installation Inspection and Testing

Following the installation of a gas fireplace insert, a thorough inspection and testing procedure is crucial to ensure proper functionality and safety. This process typically involves a licensed inspector or qualified technician who verifies that the installation adheres to local building codes and manufacturer specifications.

The inspector will examine the venting system for proper sealing, clearances, and overall integrity. The gas line connections are meticulously checked for leaks using a gas leak detector. The functionality of the ignition system, burner, and blower fan are assessed to ensure they operate correctly. The accuracy of the thermostat and safety shut-off mechanisms are also verified. The technician will also measure the carbon monoxide levels in the vicinity of the fireplace to confirm safe operation.

Homeowners should receive detailed instructions on the operation and maintenance of the gas fireplace insert. This includes information on lighting procedures, thermostat settings, cleaning schedules, and troubleshooting tips. It is recommended to keep a record of all maintenance and repairs performed on the fireplace for future reference. A post-installation checklist should be completed and signed by both the installer and the homeowner to document the inspection process and verify that all safety checks have been performed.

Fireplace Insert Installation Wood Inserts Gas Pellet And Electric

How To Install A Fireplace Insert Diy Save Money

Convert To Gas Installing Fireplace Inserts Doctor Flue

How To Install Gas Fireplace Insert Heat Glo

What Is A Gas Insert Comfort By Design

Best Fireplace Insert Repair Installs Ton Service

Why Get A Fireplace Insert Wood Gas Inserts In Tn Al

Installing A Gas Fireplace

How To Install Gas Fireplace Insert Heat Glo

Install A Gas Fireplace Insert For You Home In The Pensacola Destin Area

Related Posts