Understanding the Fireplace Damper Plate: Function, Maintenance, and Replacement

The fireplace damper plate, a critical component of any traditional masonry or prefabricated fireplace system, plays a significant role in energy efficiency, safety, and overall performance. This article provides a detailed overview of the fireplace damper plate, covering its function, common issues, maintenance requirements, and the process of replacement.

A fireplace is designed to provide warmth and ambiance, but it also presents a significant point of energy loss when not in use. Without a properly functioning damper, heated or cooled air from the house can escape up the chimney, leading to increased energy bills and uncomfortable drafts. Conversely, during periods of rain or snow, precipitation can enter the home through the chimney opening if the damper is not effectively sealed. The damper plate is specifically designed to prevent these energy losses and protect the home from the elements.

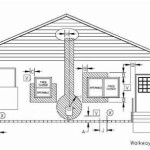

Typically constructed of cast iron or a similar durable metal, the damper plate sits at the base of the chimney, just above the firebox. Its primary function is to seal off the chimney flue when the fireplace is not in operation. This seal prevents the escape of conditioned air and the entry of unwanted elements. The damper plate is operated by a lever, chain, or handle, allowing homeowners to easily open or close the flue as needed.

Functionality and Types of Fireplace Dampers

The primary function of the fireplace damper is to regulate the airflow within the chimney. When open, it allows smoke and combustion gases to safely exit the house during a fire. When closed, it prevents drafts and minimizes energy loss when the fireplace is not in use. The efficiency of a fireplace damper directly impacts the energy performance of the home.

Several types of fireplace dampers exist, each with its own advantages and disadvantages:

*Throat Dampers:

These are the traditional dampers located just above the firebox, within the throat of the fireplace. They consist of a hinged metal plate that pivots to open or close the flue. While relatively inexpensive, throat dampers often do not provide a tight seal, leading to significant air leakage. They can also be prone to rust and warping due to their proximity to the fire. *Top-Sealing Dampers:

Also known as chimney top dampers, these units mount on top of the chimney, providing a more airtight seal than throat dampers. They typically feature a silicone gasket that presses against the chimney flue when closed. Top-sealing dampers are more effective at preventing air leakage and can also protect the chimney from rain, snow, and animals. They are generally more expensive than throat dampers but offer improved energy efficiency. *Energy-Saving Dampers:

These dampers are designed with enhanced sealing mechanisms and insulation to minimize air leakage and heat loss. They may incorporate features such as inflatable bladders or insulated panels to provide a tighter seal. While more costly, energy-saving dampers can offer significant long-term energy savings.The choice of damper type depends on factors such as budget, energy efficiency goals, and the existing fireplace configuration. A professional chimney sweep or fireplace technician can provide guidance on selecting the most appropriate damper for a specific situation.

Common Problems with Fireplace Dampers

Over time, fireplace dampers can develop various problems that compromise their functionality and efficiency. Regular inspection and maintenance are essential to identify and address these issues promptly.

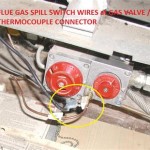

*Rust and Corrosion:

Throat dampers, in particular, are susceptible to rust and corrosion due to their exposure to heat, moisture, and combustion byproducts. Rust can weaken the metal, making the damper difficult to operate and preventing it from forming a tight seal. Corrosion can also lead to the damper breaking or falling apart. *Warping and Distortion:

High temperatures can cause the damper plate to warp or distort, preventing it from closing properly. Warping can also occur due to physical impact or improper installation. A warped damper will not provide an airtight seal, resulting in air leakage and energy loss. *Sticking or Binding:

The damper mechanism may become stuck or bind due to rust, debris, or misalignment. This can make it difficult to open or close the damper, potentially trapping smoke inside the house or preventing the fireplace from being used effectively. Forcefully attempting to open or close a stuck damper can cause further damage. *Missing or Damaged Components:

The damper handle, lever, or chain can break or become disconnected, rendering the damper inoperable. Similarly, the damper plate itself may crack or break, requiring replacement. Damaged components should be repaired or replaced promptly to restore the damper's functionality. *Obstructions and Debris:

Birds, squirrels, leaves, and other debris can accumulate in the chimney and obstruct the damper, preventing it from closing fully. Regular chimney sweeping is essential to remove these obstructions and ensure proper damper operation. A buildup of creosote can also hinder the damper's movement.Recognizing these common problems is crucial for maintaining a safe and efficient fireplace. Addressing these issues promptly can prevent further damage and ensure the fireplace operates as intended.

Maintaining and Replacing a Fireplace Damper

Regular maintenance is essential for ensuring the fireplace damper operates efficiently and safely. A well-maintained damper can help prevent energy loss, protect the home from the elements, and extend the lifespan of the fireplace system. When maintenance is no longer sufficient, replacement becomes necessary.

*Regular Inspection:

Inspect the damper at least once a year, preferably before the start of the heating season. Check for signs of rust, corrosion, warping, and damage. Ensure the damper opens and closes smoothly and that the handle, lever, or chain is securely attached. *Cleaning:

Remove any debris, such as leaves, twigs, or bird nests, that may be obstructing the damper. Use a wire brush to remove rust and corrosion. Consider applying a high-temperature lubricant to the damper mechanism to ensure smooth operation. *Chimney Sweeping:

Schedule regular chimney sweeping to remove creosote and other deposits that can accumulate in the flue and hinder the damper's movement. Professional chimney sweeps can also inspect the damper for damage and recommend necessary repairs or replacements. *Repairing Minor Damage:

Minor damage, such as a loose handle or a small amount of rust, can often be repaired with basic tools and materials. However, more extensive damage, such as a cracked damper plate or a severely corroded mechanism, may require professional repair or replacement.When the damper is beyond repair, replacement is necessary. The replacement process typically involves the following steps:

1.Choosing a Replacement Damper:

Select a replacement damper that is compatible with the existing fireplace and chimney. Consider the type of damper (throat damper, top-sealing damper, or energy-saving damper), the size of the flue, and the material of construction. 2.Removing the Old Damper:

Carefully remove the old damper, taking care not to damage the surrounding masonry or chimney components. Depending on the type of damper, this may involve removing screws, bolts, or other fasteners. In some cases, the old damper may be cemented in place and require chiseling or prying to remove it. 3.Installing the New Damper:

Install the new damper according to the manufacturer's instructions. Ensure that it is properly aligned and securely fastened. For top-sealing dampers, this may involve mounting the unit on top of the chimney and connecting it to an operating cable that runs down the flue. 4.Testing the Damper:

Once the new damper is installed, test it to ensure that it opens and closes smoothly and that it provides a tight seal when closed. Adjust the operating mechanism as needed to achieve optimal performance.Replacing a fireplace damper can be a complex task, particularly for older or custom-built fireplaces. It is often best to hire a qualified chimney sweep or fireplace technician to perform the replacement to ensure that it is done correctly and safely.

By understanding the function, maintenance, and replacement of the fireplace damper plate, homeowners can ensure the safe and efficient operation of their fireplaces for years to come. Proper care and timely replacement are essential for maximizing energy savings and preventing potential safety hazards.

Vestal Cast Iron Fireplace Damper Plate For 36 Inch Dampers

Vestal Cast Iron Fireplace Damper Plate For 42 Inch Dampers

What Is A Chimney Damper Full Service

How To Fix A Stuck Fireplace Damper The Blog At Fireplacemall

Fireplace Damper Repair Full Service Chimney Kansas City

What Is A Chimney Damper Why It Important

36 Vestal Cast Iron Replacement Damper Plate 36vp

Fireplace Dampers The Blog At Fireplacemall

Antique Original Soot Flap Damper Plate Fireplace Old Cast Iron Cover

What Is A Chimney Damper Full Service

Related Posts