Understanding Fireplace Pipe for Wood Burning Stoves

The fireplace pipe, also known as stove pipe or chimney connector pipe, is a crucial component of any wood-burning stove or fireplace system. It serves as the conduit through which combustion byproducts, including smoke, gases, and particulate matter, are safely exhausted from the appliance and released into the atmosphere. Selecting and installing the correct type of fireplace pipe is paramount for safety, efficiency, and compliance with local building codes. A poorly installed or inadequate pipe can lead to dangerous conditions such as carbon monoxide poisoning, chimney fires, and reduced heating performance.

This article provides a comprehensive overview of fireplace pipe for wood burning stoves, covering different types, materials, installation considerations, maintenance requirements, and essential safety precautions.

Types of Fireplace Pipe

Fireplace pipes are categorized based on their construction, intended use, and certification. Understanding these distinctions is crucial for selecting the appropriate pipe for a specific wood-burning appliance and installation.

Single-Wall Stove Pipe: This is the most basic type of fireplace pipe, typically constructed from black steel or stainless steel. It's designed for connecting the wood-burning stove to the chimney system within the same room. Single-wall pipes are not insulated and radiate significant heat, making them unsuitable for passing through walls, ceilings, or combustible materials. They are generally more affordable than double-wall or insulated pipes. Local codes often restrict the length of single-wall stove pipe to a maximum of 10 feet, and it requires specific clearances from combustible materials.

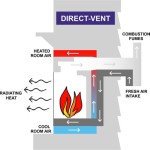

Double-Wall Stove Pipe: Double-wall stove pipe features two layers of metal with an air space between them. This design provides improved insulation compared to single-wall pipes, reducing the surface temperature and allowing for closer clearances to combustible materials. Double-wall pipes are often used in situations where single-wall pipes cannot meet the required safety clearances. They generally offer better draft performance due to maintaining higher flue gas temperatures.

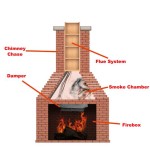

Insulated Chimney Pipe: Insulated chimney pipe is designed for passing through walls, ceilings, and roofs. It consists of multiple layers of metal and insulation, providing superior thermal protection and minimizing the risk of chimney fires. These pipes are often referred to as "Class A" chimney pipe, indicating that they meet stringent safety standards for through-the-wall and through-the-roof installations. Insulated chimney pipe is typically required for installations where the chimney system is not masonry.

Flexible Chimney Liners: Flexible chimney liners are used to reline existing masonry chimneys that are damaged or inadequate for wood-burning stoves. These liners are typically made of stainless steel and can be easily installed into existing chimney flues. They provide a smooth, continuous pathway for exhaust gases, improving draft and preventing leaks. They are also useful when the existing chimney is not the correct size or shape for the wood stove.

Material Considerations

The material used to manufacture fireplace pipe significantly impacts its durability, safety, and performance. Common materials include:

Black Steel: Black steel stove pipe is a cost-effective option for connecting a wood-burning stove to the chimney. It is typically made of 22 or 24-gauge steel with a black painted finish. Black steel pipe is suitable for interior use only and requires regular inspection and maintenance to prevent rust and corrosion. It's important to select a black steel specifically rated for stovepipe use, as standard steel pipe may not withstand the high temperatures involved.

Stainless Steel: Stainless steel fireplace pipe offers superior corrosion resistance and longevity compared to black steel. It is available in various grades, with 304 and 316 stainless steel being the most common. Stainless steel is suitable for both interior and exterior applications and is especially recommended for coastal areas or locations with high humidity. Double-wall and insulated chimney pipes are frequently constructed with stainless steel inner and outer walls.

Galvanized Steel: Galvanized steel is steel that has been coated with zinc to prevent rusting. While galvanized steel can withstand higher temperatures than bare steel, it is not recommended for use as a stovepipe. At high temperatures, galvanized steel can release toxic zinc fumes, which are a health hazard. For this reason, galvanized pipe should never be used in direct contact with flue gasses.

Ceramic: While not typically used for the entire length of the stovepipe, ceramic materials are used in some specialized components, such as chimney caps or sections of insulated chimney. Ceramic offers excellent heat resistance and can be very durable, but it can also be more brittle than metal options.

Installation and Safety Guidelines

Proper installation is critical for ensuring the safe and efficient operation of a wood-burning stove. It is highly recommended to consult with a qualified professional when planning and executing a fireplace pipe installation. Adherence to local building codes and manufacturer's instructions is essential.

Clearance to Combustibles: Maintaining adequate clearance between the fireplace pipe and combustible materials is paramount to prevent fire hazards. Clearance requirements vary depending on the type of pipe, the fuel being burned, and local regulations. Consult manufacturer's specifications and local building codes for specific clearance requirements. Non-combustible materials such as brick or concrete board should be used as heat shields to reduce clearance distances when possible.

Proper Pipe Assembly: Ensure that all pipe sections are securely connected using appropriate fasteners, such as screws or clamps. Pipe joints should be sealed with high-temperature silicone sealant to prevent leaks of smoke and gases. The correct orientation of pipe sections is also important, with the crimped end of the pipe fitting inside the non-crimped end to prevent creosote from leaking. Follow the manufacturer's instructions precisely for proper assembly.

Chimney Height: The chimney should extend at least three feet above the highest point where it passes through the roof and at least two feet higher than any structure within ten feet. This height ensures adequate draft and prevents downdrafts that could cause smoke to enter the building. Insufficient chimney height can significantly reduce the efficiency of the wood-burning stove and increase the risk of chimney fires.

Draft Considerations: Proper draft is essential for efficient combustion and preventing smoke from entering the building. Factors that can affect draft include chimney height, pipe diameter, outside temperature, and wind conditions. Ensure that the chimney is properly sized for the wood-burning appliance and that there are no obstructions that could impede airflow. Installing a barometric damper can help to regulate draft and prevent overfiring of the stove.

Thimble Installation: When passing a stovepipe through a wall or ceiling, use a properly installed thimble. A thimble is a non-combustible sleeve that protects combustible materials from the heat of the stovepipe. Select a thimble that is specifically designed for use with wood-burning stoves and install it according to the manufacturer's instructions. The thimble should provide adequate clearance between the stovepipe and combustible materials.

Chimney Cap: Install a chimney cap to prevent rain, snow, leaves, and animals from entering the chimney. A chimney cap also helps to prevent downdrafts and improve draft performance. Choose a chimney cap that is made of durable materials such as stainless steel and that is properly sized for the chimney flue.

Maintenance and Inspection

Regular maintenance and inspection are essential for ensuring the continued safe and efficient operation of a wood-burning stove system. Neglecting maintenance can lead to dangerous conditions such as chimney fires and carbon monoxide poisoning.

Creosote Buildup: Creosote is a highly flammable byproduct of wood combustion that accumulates inside the fireplace pipe and chimney. Regular cleaning is necessary to remove creosote buildup and prevent chimney fires. The frequency of cleaning depends on the type of wood burned, the burning habits, and the design of the stove and chimney system. A qualified chimney sweep should inspect the chimney at least once a year and clean it as needed. Signs of excessive creosote buildup include a thick, shiny black coating inside the pipe and chimney.

Pipe Inspection: Regularly inspect the fireplace pipe for signs of damage, such as rust, corrosion, cracks, or loose connections. Replace any damaged pipe sections immediately. Pay particular attention to pipe joints and connections, ensuring that they are securely fastened and properly sealed. Check for signs of leaks, such as smoke stains or creosote deposits around pipe joints.

Damper Operation: Ensure that the stove's damper operates smoothly and effectively. A properly functioning damper allows for control over the air supply to the fire, which is essential for efficient combustion and preventing overfiring. Clean the damper regularly to remove soot and creosote buildup.

Professional Inspections: Schedule regular inspections by a qualified chimney sweep to assess the overall condition of the chimney system. A professional chimney sweep can identify potential problems, such as cracks in the chimney liner, deteriorated mortar joints, or obstructions in the flue. They can also provide valuable advice on proper maintenance and operation of the wood-burning stove.

Carbon Monoxide Detectors: Install carbon monoxide (CO) detectors on every level of the home, especially near sleeping areas. Carbon monoxide is a colorless, odorless gas that can be deadly. Test the CO detectors regularly and replace the batteries as needed. If a CO alarm sounds, immediately evacuate the building and call emergency services.

Wood Storage: Store firewood in a dry, well-ventilated area to prevent rot and mold growth. Seasoned wood burns more efficiently and produces less creosote than green wood. Avoid storing firewood indoors, as it can attract insects and rodents. Keep a small supply of wood near the stove for convenience.

Using the correct Fireplace Pipe ensures the safety and efficiency of any wood-burning appliance. Careful in planning, installation and maintenance is necessary to protect everyone in the building.

Wood Burning Stove Chimney Installation

Chimney And Venting Pipe Guide Fireplaces Direct Learning Center

Wood Burning Fireplaces Inserts Full Service Chimney

What Accessories And Parts Do I Need To Fit A Wood Burning Stove Supermarket

Wood Burner Flue Woodburner Flues

The Balanced Flue Everything You Need To Know Island Pellet Stoves

How To Build Heat Shields For Wood Stoves Tiny Stove

Starter Pipe Ø 150mm 6inch 500mm Black Matt Britedirect

Can You Install A Wood Burning Stove In An Existing Fireplace

Your Guide To Wood Stove Installation Full Service Chimney