Fireplace Pellet Inserts: A Comprehensive Guide

Fireplace pellet inserts offer a modern and efficient alternative to traditional wood-burning fireplaces. These inserts are designed to fit into existing fireplace openings, transforming them into powerful and clean-burning heating appliances. They utilize compressed wood pellets, a renewable and sustainable fuel source, to generate heat. Unlike open fireplaces, which often lose heat up the chimney, pellet inserts are highly efficient, directing most of the generated warmth into the living space. This article explores the key aspects of fireplace pellet inserts, including their benefits, operational features, installation requirements, and maintenance procedures.

Understanding the Benefits of Fireplace Pellet Inserts

Pellet inserts offer numerous advantages over traditional wood-burning fireplaces and other heating options. One of the primary benefits is their efficiency. Standard open fireplaces are notoriously inefficient, with a significant portion of the heat escaping through the chimney. Pellet inserts, however, boast efficiency ratings of 75% or higher, meaning that a much larger percentage of the fuel's energy is converted into usable heat for the home. This increased efficiency translates to lower heating costs and reduced fuel consumption.

Another significant advantage is the clean-burning nature of pellet inserts. Wood pellets are a processed fuel source, manufactured from compressed sawdust and wood waste. This manufacturing process results in a fuel with a low moisture content and consistent density, leading to more complete combustion. As a result, pellet inserts produce significantly less smoke, soot, and creosote compared to traditional wood-burning fireplaces. This reduced emission level contributes to cleaner air quality, both indoors and outdoors, and minimizes the risk of chimney fires caused by creosote buildup.

Convenience is another key benefit of pellet inserts. Unlike wood-burning fireplaces, which require manually loading wood, pellet inserts feature a hopper that automatically feeds pellets into the firebox. This automatic feeding system allows for extended burn times and more consistent heat output. Many pellet inserts also come equipped with thermostats and programmable timers, allowing users to precisely control the temperature and heating schedule of their homes. This level of automation provides a level of comfort and convenience that is unmatched by traditional fireplaces.

Finally, the environmental benefits of pellet fuel are substantial. Wood pellets are a renewable resource, sourced from sustainably managed forests. By utilizing wood waste and byproducts, pellet production helps to reduce landfill waste and promote responsible forestry practices. Furthermore, the low emissions of pellet inserts contribute to improved air quality and a reduced carbon footprint compared to fossil fuel-based heating systems.

Operational Features and Technology

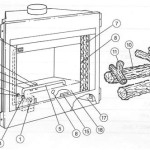

The operation of a fireplace pellet insert involves a sophisticated system that ensures efficient and safe heating. The core component is the hopper, which holds a supply of wood pellets. The size of the hopper determines the burn time of the insert, with larger hoppers allowing for longer periods between refueling. From the hopper, pellets are fed into the firebox by an auger, a screw-like mechanism that precisely controls the amount of fuel delivered to the fire.

Ignition is typically accomplished using an electric igniter, which heats up and ignites the pellets. Once the fire is established, a combustion fan ensures a constant supply of air to the firebox, promoting efficient burning. The heat generated by the fire is then distributed into the room through a convection fan, which circulates warm air throughout the living space. The speed of the convection fan can often be adjusted to control the rate of heat output.

Modern pellet inserts are often equipped with electronic controls that allow for precise temperature regulation and programmable operation. Thermostats maintain a desired room temperature by automatically adjusting the pellet feed rate and fan speed. Programmable timers allow users to set specific heating schedules, ensuring that the home is warm when needed and conserving fuel when it is not. These electronic controls enhance the convenience and efficiency of pellet inserts.

Safety features are also an integral part of pellet insert design. Most models include safety sensors that monitor the operation of the insert and automatically shut it down in the event of a malfunction, such as overheating or a blocked exhaust vent. These safety features provide peace of mind and ensure the safe operation of the appliance.

Installation and Maintenance Requirements

Proper installation is crucial for the safe and efficient operation of a fireplace pellet insert. It is generally recommended that installation be performed by a qualified professional who is familiar with local building codes and manufacturer's instructions. The installation process typically involves preparing the existing fireplace opening, connecting the insert to a dedicated chimney liner, and wiring the unit to an electrical outlet.

The chimney liner is a critical component of the installation. It is essential to use a liner that is specifically designed for pellet stoves, as it must be able to withstand the high temperatures and corrosive byproducts of pellet combustion. The liner must also be properly sized to ensure adequate draft and prevent the buildup of creosote. A poorly installed or improperly sized chimney liner can lead to dangerous conditions, such as carbon monoxide poisoning or chimney fires.

Regular maintenance is essential for maintaining the performance and longevity of a pellet insert. The frequency of maintenance will depend on the amount of use and the quality of the fuel being burned. However, some routine maintenance tasks should be performed regularly. These include cleaning the firebox, removing ash buildup, and inspecting the chimney liner.

Cleaning the firebox involves removing any accumulated ash and debris from the burning chamber. This can be done using a vacuum cleaner or a brush and dustpan. Ash buildup can impede airflow and reduce the efficiency of the insert. It is generally recommended to clean the firebox at least once a week during the heating season.

The chimney liner should be inspected annually for any signs of damage or creosote buildup. Creosote is a flammable substance that can accumulate in the chimney as a result of incomplete combustion. If significant creosote buildup is present, it should be removed by a professional chimney sweep. Regular chimney inspections and cleaning are essential for preventing chimney fires.

In addition to these routine maintenance tasks, it is also important to periodically inspect the various components of the pellet insert, such as the auger, fans, and sensors. Any worn or damaged parts should be replaced promptly to ensure the continued safe and efficient operation of the appliance. Consulting the manufacturer's manual for specific maintenance recommendations is always advisable.

Selecting the appropriate size and British Thermal Unit (BTU) output is critical. BTU refers to the amount of heat the unit can generate per hour. An oversized unit will cycle on and off frequently, leading to inefficient operation and potential discomfort. An undersized unit will struggle to maintain a comfortable temperature, especially during colder periods. A professional can assess the heating needs of the space and recommend the appropriate BTU output.

The quality of pellets used significantly impacts performance and maintenance requirements. Using low-quality pellets can result in higher ash production, increased creosote buildup, and reduced heating efficiency. Opting for premium-grade pellets that meet or exceed industry standards is a worthwhile investment. High-quality pellets burn cleaner, produce less ash, and deliver more consistent heat. Check the Pellet Fuels Institute (PFI) grading system when selecting pellets.

Addressing common issues such as ignition problems, auger malfunctions, and sensor failures promptly is important. Ignition problems can often be resolved by cleaning the igniter or replacing it if necessary. Auger malfunctions may be caused by obstructions in the feed path or a worn auger motor. Sensor failures can result in inaccurate temperature readings or safety shutdowns. Consulting the owner's manual and seeking professional assistance when needed are crucial for resolving these issues effectively.

Pellet Fireplace Inserts Lopi Stoves Made In Usa

Pellet Fireplace Inserts Lopi Stoves Made In Usa

Pellet Fireplace Inserts Complete Home Concepts

Pellet Fireplace Inserts Lopi Stoves Made In Usa

Fireplace Insert Stoves Wood Gas Pellet Traditional Baltimore Maryland

Wood Stoves Pellet Gas Fireplace Inserts

Fireplace Insert Installation Wood Inserts Gas Pellet And Electric

Hampton Greenfire Gci60 Pellet Insert Chimney Drs

Agp Pellet Insert By Lopi Higgins Energy Alternatives

Pellet Stove Inserts Turn Drafty Fireplaces Into Heaters Complete Home Concepts