Heat Resistant Mortar for Fireplace Applications

Fireplaces provide warmth and ambiance to residential and commercial spaces, but their functionality depends on the integrity of the materials used in their construction. The high temperatures generated during burning necessitate the use of specialized mortars designed to withstand extreme heat. Heat resistant mortar plays a critical role in ensuring the structural stability and safety of a fireplace by binding together bricks, stones, or other masonry units. This article explores the characteristics, applications, and considerations associated with heat resistant mortar used in fireplace construction and repair.

Standard mortar, composed of cement, lime, and sand, lacks the necessary properties to endure the continuous thermal cycling and high temperatures present within a fireplace. Exposure to intense heat causes standard mortar to degrade, leading to cracking, crumbling, and ultimately, the weakening of the fireplace structure. Heat resistant mortar, in contrast, is formulated with specialized additives and aggregate materials that enhance its ability to withstand extreme temperatures without compromising its structural integrity. These additives can include materials like fireclay, alumina, and other high-temperature resistant compounds. The specific composition of a heat resistant mortar will vary depending on its intended application and the maximum temperature it is designed to endure.

Understanding the Composition and Properties of Heat Resistant Mortar

The composition of heat resistant mortar is significantly different from conventional mortar to provide the necessary thermal resistance. A key ingredient is often fireclay, a type of clay that can withstand high temperatures without significant deformation or loss of strength. Fireclay becomes ceramic-like when heated, providing a strong and durable bond. Other additives, such as alumina and silica, further enhance the mortar's ability to withstand thermal shock, which is the rapid change in temperature that can cause cracking. The type of aggregate used in the mortar also plays a critical role. Instead of standard sand, heat resistant mortars often incorporate specialized aggregates like calcined flint clay or expanded shale, which offer superior heat resistance and lower thermal expansion properties. The proportions of these ingredients are carefully controlled to achieve the desired performance characteristics.

One of the most important properties of heat resistant mortar is its ability to maintain its bond strength at high temperatures. Ordinary mortar will lose its strength significantly as temperatures rise, leading to a weakened structure. Heat resistant mortar, however, retains a substantial portion of its strength even at temperatures exceeding 1000°F. This ensures that the fireplace remains structurally sound, preventing the bricks or stones from shifting or falling out of place. Another crucial property is its resistance to thermal expansion and contraction. Materials expand when heated and contract when cooled. If the mortar and the bricks or stones expand and contract at different rates, it can lead to stress fractures and eventual failure. Heat resistant mortars are formulated to have a thermal expansion coefficient that closely matches that of the surrounding masonry units, minimizing the risk of cracking.

Applications of Heat Resistant Mortar in Fireplace Construction and Repair

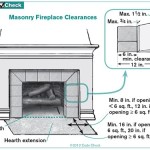

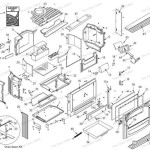

Heat resistant mortar is an indispensable material in various aspects of fireplace construction and repair. Its primary application is in the construction of the firebox, the area where the fire is actually burned. The firebox experiences the most intense heat, making it crucial to use a mortar that can withstand these extreme conditions. Heat resistant mortar is used to bond the firebricks that line the firebox, creating a strong and durable barrier that protects the surrounding structure from the heat of the fire. Similarly, it is used in the construction of chimney liners, which are designed to vent hot gases and smoke away from the building. The flue liner is subjected to high temperatures and corrosive combustion byproducts, requiring a mortar that can withstand these harsh conditions.

Beyond new construction, heat resistant mortar is commonly used in fireplace repair. Over time, the mortar joints in a fireplace can deteriorate due to exposure to heat, moisture, and corrosive gases. This can lead to cracks, crumbling, and even the collapse of sections of the fireplace. Repointing, the process of removing damaged mortar and replacing it with new mortar, is a common maintenance task. When repointing a fireplace, it is essential to use heat resistant mortar to ensure that the repair is durable and long-lasting. Furthermore, heat resistant mortar can be used to repair cracks in firebricks or to replace damaged firebricks altogether. It is important to select a mortar that is compatible with the existing firebricks and that can withstand the temperatures within the firebox.

Key Considerations When Selecting and Using Heat Resistant Mortar

Selecting the appropriate heat resistant mortar for a specific fireplace application requires careful consideration of several factors. The maximum temperature that the mortar will be exposed to is a primary concern. Different mortars are formulated to withstand different temperature ranges. It is crucial to choose a mortar that is rated for temperatures that are slightly higher than the expected maximum temperature within the fireplace. The type of masonry units being used is another important consideration. Different types of bricks or stones have different properties, and it is essential to select a mortar that is compatible with them. For example, some mortars are specifically designed for use with firebricks, while others are suitable for use with natural stones.

Proper application of heat resistant mortar is essential to ensure its effectiveness. The mortar should be mixed according to the manufacturer's instructions, using the correct amount of water to achieve the desired consistency. The joints between the bricks or stones should be completely filled with mortar, ensuring a strong and durable bond. It is also important to allow the mortar to cure properly before using the fireplace. Curing involves keeping the mortar moist for a specified period of time, allowing it to fully harden and develop its strength. Failure to cure the mortar properly can lead to cracking and premature failure. Additionally, safety precautions should be observed when working with heat resistant mortar. Wear appropriate personal protective equipment, such as gloves and eye protection, to prevent skin and eye irritation. Work in a well-ventilated area to avoid inhaling dust or fumes.

Regular inspection and maintenance of the fireplace are crucial to identify and address any potential problems early on. Look for cracks, crumbling, or other signs of deterioration in the mortar joints. If any damage is detected, it should be repaired promptly to prevent further weakening of the fireplace structure. By selecting the appropriate heat resistant mortar and following proper installation and maintenance procedures, homeowners and contractors can ensure the longevity and safety of their fireplaces.

Heat Stop High Temp Premixed Mortar In Beige Color

Heatproof Mortar 10kg Bucket For Fireplaces And Stoves Vitcas

Sakrete 50 Lb Mortar Mix In The Concrete Cement Stucco Mixes Department At Com

Heat Stop High Temp Premixed Mortar In Beige Color

Heat Stop 50

Fire Rated Mortar 10kg Dingo Cement

Hot Spot Ready To Use Mortar Fireplace Repairer

Refractory Mortar Types And Construction Practice The Constructor

Dap Black High Heat Fire Resistant Mortar Sealant Chimneys Fireplace

Quikrete 10 Oz Fireplace Repair Mortar 862024 The Home Depot

Related Posts