Fireplace Clay Flue Pipe Liners: A Comprehensive Overview

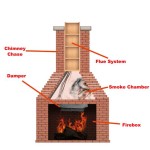

Fireplace clay flue pipe liners are essential components of a chimney system, responsible for safely venting combustion byproducts from a fireplace, furnace, or other heating appliance. These liners form a protective barrier within the chimney, safeguarding the chimney structure and the surrounding building from the damaging effects of heat, corrosive gases, and creosote buildup. Understanding their purpose, construction, maintenance, and potential issues is paramount for homeowners and professionals involved in chimney construction and maintenance.

The primary function of a clay flue liner is to contain the products of combustion and direct them upwards and out of the building. This process is crucial for preventing carbon monoxide poisoning, which can occur if exhaust gases leak into the living spaces. Furthermore, they protect the chimney masonry from degradation caused by the acidic nature of flue gases. Without a proper lining, the chimney structure can crumble, leading to structural instability and potential fire hazards. The selection and installation of appropriate flue liners depend on several factors, including the type of appliance being vented, the size of the chimney, and local building codes.

Historically, clay flue liners have been the traditional material used for chimney lining due to their relative affordability and availability. While newer materials such as stainless steel and cast-in-place liners have emerged, clay liners remain a viable option for many applications. However, it is important to be aware of their limitations and vulnerabilities to ensure safe and efficient operation of the chimney system.

Key Point 1: Composition and Manufacturing of Clay Flue Liners

Clay flue liners are manufactured from high-temperature-resistant clay, typically a mixture of shale and other ceramic materials. The manufacturing process involves several stages, starting with the grinding and mixing of raw materials. The resulting clay mixture is then extruded or molded into the desired shape, usually rectangular or round sections. These sections are then dried to remove moisture and subsequently fired in a kiln at high temperatures, typically exceeding 2000 degrees Fahrenheit. This firing process vitrifies the clay, making it hard, durable, and resistant to heat and corrosive substances.

The firing process is critical for achieving the desired properties of the flue liner. Proper firing ensures that the clay becomes non-porous and capable of withstanding the extreme temperature fluctuations and chemical attacks that occur during chimney operation. Imperfectly fired liners can be more susceptible to cracking and deterioration, compromising the integrity of the chimney system.

Clay flue liners are typically manufactured in standard sizes and lengths, allowing for easy installation within the chimney structure. They are often joined together with refractory mortar, creating a continuous and sealed flue passage. The mortar fills the gaps between the liner sections, preventing leaks and ensuring proper venting.

The dimensions of the flue liner are critical and must be appropriate for the appliance being vented. An undersized flue can lead to inadequate draft, resulting in incomplete combustion and the buildup of dangerous gases. Conversely, an oversized flue can cool too quickly, leading to condensation and creosote formation, which can increase the risk of chimney fires.

Key Point 2: Advantages and Disadvantages of Clay Flue Liners

Clay flue liners offer several advantages that have contributed to their widespread use in chimney construction. One of the primary benefits is their cost-effectiveness, as they are generally more affordable than other lining materials like stainless steel. They are also relatively easy to install, especially in new construction, where they can be integrated seamlessly into the chimney structure. Furthermore, they are relatively resistant to the corrosive effects of most flue gases, providing a reasonable lifespan when properly maintained.

However, clay flue liners also have several limitations that need to be considered. They are susceptible to cracking, particularly from rapid temperature changes or thermal shock. This can occur when a hot fire is started in a cold chimney, causing the clay to expand quickly and unevenly. Cracks can also develop over time due to settling of the chimney structure or exposure to moisture. Once cracked, the liner loses its ability to contain flue gases, potentially leading to leaks and structural damage to the chimney.

Another disadvantage of clay flue liners is their susceptibility to damage from direct contact with fire. If a chimney fire occurs, the intense heat can cause the clay to spall (flake) or crack, further compromising the integrity of the lining. This is why regular chimney inspections are crucial to identify and address any potential problems before they escalate.

Compared to stainless steel liners, clay liners are also heavier and more brittle, making them more difficult to repair or replace in existing chimneys. The process of removing and replacing damaged clay liners can be labor-intensive and expensive, often requiring partial dismantling of the chimney structure.

Key Point 3: Inspection, Maintenance, and Repair of Clay Flue Liners

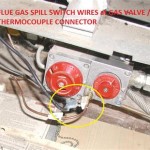

Regular inspection and maintenance are essential for ensuring the safe and efficient operation of a chimney with clay flue liners. The Chimney Safety Institute of America (CSIA) recommends annual inspections by a qualified chimney sweep. These inspections involve a visual examination of the flue liner to identify any cracks, spalling, or deterioration. The chimney sweep may also use specialized equipment, such as a chimney camera, to thoroughly inspect the interior of the flue liner.

During the inspection, the chimney sweep will also check for creosote buildup. Creosote is a combustible byproduct of burning wood, and it can accumulate in the flue liner over time. Excessive creosote buildup can significantly increase the risk of a chimney fire. If creosote is present, the chimney sweep will clean the flue liner using appropriate tools and techniques.

If cracks or other damage are detected in the clay flue liner, repairs may be necessary. Small cracks can sometimes be repaired using a refractory mortar or sealant. However, larger cracks or more extensive damage may require the replacement of the affected liner sections. In some cases, it may be more cost-effective to reline the entire chimney with a different material, such as stainless steel, which offers greater durability and resistance to cracking.

Several factors can contribute to the premature deterioration of clay flue liners. These include burning unseasoned wood, which produces more creosote and corrosive gases; improper chimney construction or installation; and lack of regular maintenance. To extend the lifespan of clay flue liners, it is important to burn only dry, seasoned wood, ensure proper ventilation and draft within the chimney, and schedule regular inspections and cleanings.

Water penetration can also significantly damage clay flue liners. Water can enter the chimney through cracks in the masonry or through a damaged chimney cap. Once inside, the water can freeze and thaw, causing the clay to expand and contract, leading to cracks and spalling. It is important to address any sources of water leakage promptly to prevent further damage to the chimney system.

Homeowners should also be aware of the signs of a failing flue liner, which may include smoke leaking into the house, unusual odors near the fireplace, or visible cracks in the chimney exterior. If any of these signs are present, it is important to contact a qualified chimney professional immediately for a thorough inspection and evaluation.

In summary, clay flue pipe liners play a critical role in ensuring the safe and efficient operation of a chimney system. While they offer several advantages, including affordability and ease of installation, they are also susceptible to cracking and damage. Regular inspection, maintenance, and timely repairs are essential for maximizing their lifespan and preventing potential hazards. When considering the installation or repair of a chimney system, it is important to consult with a qualified professional to determine the most appropriate lining material and ensure compliance with local building codes.

Clay Chimney Flue Liners Capitol City Lumber

8 Advantages Of Using A Clay Chimney Liner

Flue Repairs And Chimney Relining A 1 Pro

Clay Lined Chimey

Superior Clay Flue Liner 8 W X 24 H 8888508 Kuhlman Direct

8 Inch Clay Straight Chimney Flue Liner Ray Grahams Diy

Chimney Flue Liner

4 5 X8 Logan Clay Flue Liners 2 Lengths Lange S Warehouse

Heatshield Cerfractory Flue Sealant Chimneysaver

Flue Lining Billing Chimneys