How To Lay Brick For a Fireplace: A Comprehensive Guide

Constructing a brick fireplace is a significant undertaking that combines aesthetic appeal with functional heat management. A well-laid brick fireplace can serve as a focal point in a room while providing efficient heating during colder months. This article provides a comprehensive guide on how to lay brick for a fireplace, covering the necessary steps from planning and preparation to the actual bricklaying process.

Planning and Preparation: The Foundation of a Successful Project

Before commencing any physical work, meticulous planning is essential. This phase involves assessing the location, designing the fireplace, calculating material requirements, and gathering the appropriate tools and safety equipment. Inadequate preparation can lead to structural issues, aesthetic inconsistencies, and potential safety hazards.

Assessing the Location: The first step involves evaluating the structural integrity of the intended location. The floor must be capable of supporting the considerable weight of the brick fireplace. Ensure the subfloor is level and free from obstructions. If the structural capacity is questionable, consultation with a structural engineer is recommended before proceeding.

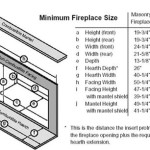

Designing the Fireplace: Fireplace design should consider both aesthetics and functionality. Consider the style of the room and the desired architectural impact. Research different fireplace designs, including traditional, modern, and corner fireplaces. Sketching a detailed plan, specifying dimensions, and indicating the brick arrangement is crucial.

Calculating Material Requirements: Accurately estimating the required materials is vital to minimize waste and ensure project continuity. Calculate the number of bricks needed based on the fireplace dimensions and the chosen brick size. Add an extra 5-10% to account for cuts and potential breakage. Additionally, determine the quantity of mortar, firebricks (for the firebox), flue tiles, and other necessary materials.

Gathering Tools and Safety Equipment: Bricklaying requires specific tools to ensure precision and efficiency. Essential tools include a brick trowel, margin trowel, brick hammer, level, plumb bob, measuring tape, mortar mixing tub, pointing trowel, and a tuckpointer. Safety equipment is equally important, encompassing safety glasses, gloves, dust mask, and appropriate work attire.

The Bricklaying Process: Step-by-Step Execution

With the planning and preparation complete, the actual bricklaying process can begin. This involves mixing the mortar, laying the foundation, constructing the firebox, building the firebox walls, creating the smoke chamber, installing the flue, and finishing the brickwork.

Mixing the Mortar: Mortar serves as the cohesive element that binds the bricks together. Use a pre-mixed mortar specifically designed for fireplaces, ensuring it is heat-resistant. Follow the manufacturer's instructions for mixing the mortar, aiming for a consistency similar to thick peanut butter. Avoid adding too much water, as this can weaken the mortar.

Laying the Foundation: The foundation provides a stable base for the fireplace. It should extend beyond the dimensions of the fireplace itself to distribute the weight effectively. A concrete slab is typically used as the foundation. Ensure the slab is level and cured before commencing bricklaying. Apply a layer of mortar to the foundation as a starting point.

Constructing the Firebox: The firebox is the chamber where the fire burns. It must be constructed with firebricks, which are designed to withstand high temperatures. These firebricks should be mortared together using refractory mortar, also known as fireclay mortar. Ensure tight joints to prevent heat leakage.

Building the Firebox Walls: The walls surrounding the firebox are crucial for structural stability and aesthetic appeal. Begin by laying the first course of bricks, ensuring it is level and aligned with the foundation. Apply mortar generously to both the horizontal and vertical joints (bed and head joints respectively). Use a level to check for plumb and alignment after each course. Maintain consistent joint spacing (typically 3/8 inch) using a brick jointer.

Creating the Smoke Chamber: The smoke chamber is the area above the firebox that funnels smoke up into the flue. The sides of the smoke chamber should slope inward, directing the smoke upward. This area may require specific fire-resistant materials depending on local building codes.

Installing the Flue: The flue is a vertical channel that carries smoke and combustion gases out of the chimney. The flue is typically constructed from ceramic flue tiles. These tiles are stacked on top of each other and mortared together, ensuring a tight seal to prevent leaks of dangerous gases like carbon monoxide. Local code enforcement agencies may dictate specific dimensions and installation methods for the flue.

Finishing the Brickwork: Once the fireplace structure is complete, the finishing touches can be applied. This involves cleaning the mortar joints, pointing the brickwork, and applying a sealant. Use a pointing trowel to compress the mortar into the joints, creating a neat and professional finish. A brick sealant can help protect the brick from moisture and weathering.

Key Considerations for Success

Several critical factors can impact the long-term performance and safety of the brick fireplace. These include adherence to building codes, proper ventilation, and regular maintenance.

Adherence to Building Codes: Complying with local building codes is non-negotiable. These codes specify requirements for fireplace construction, including minimum clearances from combustible materials, fireplace dimensions, and flue specifications. Contacting the local building department is crucial to obtain the necessary permits and ensure compliance.

Proper Ventilation: Adequate ventilation is vital for safe fireplace operation. The chimney must be properly sized to ensure sufficient draft, which draws smoke and gases upwards. Blocked or obstructed chimneys pose a significant risk of carbon monoxide poisoning. Regular inspection and cleaning of the chimney are necessary to maintain proper ventilation.

Regular Maintenance: Brick fireplaces require regular maintenance to ensure optimal performance and longevity. This includes cleaning the firebox, inspecting the chimney for cracks or damage, and re-pointing the mortar joints as needed. Addressing minor issues promptly can prevent more significant and costly repairs in the future.

Building a brick fireplace is a challenging but rewarding project. By meticulously following the steps outlined in this guide, attending to detail, and adhering to safety precautions, it is possible to construct a beautiful and functional fireplace that will provide warmth and enjoyment for many years to come. Always consult with qualified professionals if uncertainties arise or for complex design elements.

Build A Fireplace Brick By Fine Homebuilding

How To Build An Indoor Fireplace The Constructor

Home Dzine Garden Tips On Building An Outdoor Fireplace Build A Backyard

How To Build A Brick Hearth Ehow

Diy Brick Fireplace

How To Build An Indoor Fireplace The Constructor

How To Install Brick On A Fireplace Our Family Maison

How To Build A Brick Fireplace Diy Part 1 Of 5

How To Build A Masonry Fireplace Morton Stones

How To Install Firebrick In Your Outdoor Stone Fireplace

Related Posts