Wood Burning Stoves and Fireplace Inserts: A Comprehensive Overview

The utilization of wood as a primary or supplementary heating source dates back millennia. Modern iterations of wood-burning appliances, specifically wood-burning stoves and fireplace inserts, offer significantly improved efficiency and reduced emissions compared to open fireplaces. This article will delve into the functionalities, benefits, considerations, and maintenance aspects of these heating solutions.

Wood-burning stoves are self-contained heating appliances designed to burn wood fuel within a closed firebox. They are typically constructed from cast iron or steel, materials recognized for their heat retention and durability. The design incorporates a chimney or flue system to effectively exhaust combustion gases. Modern stoves are engineered to maximize heat output while minimizing smoke and particulate emissions, often meeting stringent environmental regulations.

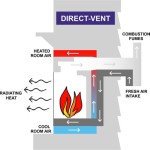

Fireplace inserts, conversely, are designed to be installed directly into an existing masonry fireplace. They essentially function as a stove within the fireplace structure, transforming an often inefficient open fireplace into a more effective heating source. Like stoves, inserts are constructed from cast iron or steel and utilize a closed firebox to control combustion. They also require a properly installed chimney liner to ensure safe and efficient venting of exhaust gases.

Both stoves and inserts offer a range of styles and sizes to accommodate diverse heating needs and aesthetic preferences. The selection of a suitable appliance hinges on factors such as the size of the area to be heated, the desired heat output, and the available space for installation.

Key Point 1: Efficiency and Environmental Considerations

A primary advantage of wood-burning stoves and fireplace inserts over traditional open fireplaces is their significantly enhanced efficiency. Open fireplaces often lose a substantial portion of heat up the chimney, resulting in low heating efficiency. Stoves and inserts, however, are designed to extract more heat from the wood fuel before the exhaust gases are vented. This is achieved through techniques such as secondary combustion, which burns off gases and particulates that would otherwise be released as smoke.

The efficiency of a wood-burning appliance is typically measured by its Heating Value (HHV) or Lower Heating Value (LHV). These values indicate the amount of usable heat produced from a given quantity of wood. Modern stoves and inserts often boast efficiency ratings exceeding 70%, a marked improvement over the single-digit efficiencies sometimes associated with open fireplaces.

Environmental regulations play a crucial role in the design and operation of wood-burning appliances. The U.S. Environmental Protection Agency (EPA) sets standards for particulate emissions from wood stoves and inserts. Appliances that meet these standards are certified as EPA-approved and are considered cleaner-burning. These regulations have driven manufacturers to develop more efficient combustion technologies and incorporate features such as catalytic combustors and non-catalytic combustion systems.

Catalytic combustors employ a catalyst to lower the ignition temperature of gases and particulates, allowing them to burn more completely. Non-catalytic combustion systems rely on advanced firebox designs to optimize airflow and fuel-air mixtures, promoting more complete combustion without the use of a catalyst.

Proper wood selection also significantly impacts emissions. Seasoned wood, which has been dried for several months, burns more cleanly and efficiently than green or wet wood. Seasoning reduces the moisture content of the wood, allowing it to burn hotter and produce less smoke. Burning unseasoned wood can lead to increased creosote buildup in the chimney, which poses a fire hazard.

The type of wood burned also affects emissions and heating value. Hardwoods, such as oak and maple, generally provide more heat per unit volume than softwoods, such as pine and fir. However, softwood can be easier to ignite and may be suitable for starting fires.

Key Point 2: Installation and Safety

Proper installation is paramount for the safe and efficient operation of wood-burning stoves and fireplace inserts. Installation should adhere to local building codes and manufacturer's instructions. It is often recommended to engage a qualified installer to ensure compliance and optimal performance.

Stoves typically require a safe clearance distance from combustible materials, such as walls, furniture, and flooring. This clearance is specified by the manufacturer and is designed to prevent overheating and potential fire hazards. Heat shields can be used to reduce clearance requirements in some cases.

Fireplace inserts necessitate the installation of a chimney liner. A chimney liner is a metal pipe that runs the length of the chimney, providing a dedicated flue for the insert's exhaust gases. This liner is essential for preventing creosote buildup in the existing masonry chimney and ensuring proper venting. Without a liner, combustion gases can leak into the home, posing a carbon monoxide poisoning risk.

Carbon monoxide detectors are essential safety devices for any home with a wood-burning appliance. Carbon monoxide is a colorless and odorless gas that can be deadly. Detectors should be installed on each level of the home and near sleeping areas. Batteries should be tested regularly and replaced as needed.

Regular chimney inspections and cleaning are crucial for maintaining safety and preventing chimney fires. Creosote, a flammable byproduct of wood combustion, can accumulate in the chimney over time. If allowed to build up, creosote can ignite, leading to a potentially dangerous chimney fire. Chimney sweeps can inspect and clean chimneys to remove creosote and ensure they are in good working order.

Proper wood storage is also important for safety. Wood should be stored in a dry, well-ventilated area away from the home to prevent infestations of insects and rodents. Stacked wood should be covered to protect it from rain and snow.

Key Point 3: Maintenance and Operation

Routine maintenance is essential for ensuring the long-term performance and safety of wood-burning stoves and fireplace inserts. This includes regular cleaning of the firebox, removal of ash, and inspection of the chimney and flue system.

Ash should be removed from the firebox on a regular basis to prevent it from building up and obstructing airflow. The frequency of ash removal depends on the amount of wood burned and the type of wood. Ash should be disposed of in a metal container with a tight-fitting lid and stored away from combustible materials.

The door gasket on the stove or insert should be inspected periodically and replaced if it is damaged or worn. A proper seal is essential for maintaining optimal combustion and preventing air leaks. Air leaks can reduce efficiency and increase emissions.

The flue system should be inspected regularly for signs of creosote buildup or damage. A chimney sweep can perform this inspection and clean the chimney if necessary. Signs of creosote buildup include black, tar-like deposits on the chimney walls.

Proper operating techniques can also enhance efficiency and reduce emissions. Starting fires with kindling and small pieces of wood can help to establish a good draft and promote complete combustion. Overloading the firebox with too much wood can restrict airflow and lead to smoldering, which produces more smoke and creosote.

Adjusting the air controls on the stove or insert can regulate the rate of combustion and heat output. Closing the air controls too tightly can starve the fire of oxygen, leading to incomplete combustion and increased emissions. Opening the air controls too much can result in rapid burning and reduced efficiency.

The use of a wood moisture meter can help to ensure that the wood being burned is properly seasoned. A moisture meter measures the moisture content of the wood. Seasoned wood should have a moisture content of less than 20%.

By adhering to proper installation guidelines, safety precautions, and maintenance practices, homeowners can safely and effectively utilize wood-burning stoves and fireplace inserts as a reliable and efficient heating source.

Ventis Hei240 Wood Burning Insert Rockford Chimney

Why A Wood Burning Fireplace Insert Bethesda Md Service

Wood Burning Fireplace Inserts Insert Installation

Wood Inserts We Love Fire

Why A Wood Burning Fireplace Insert Bethesda Md Service

Napoleon Epi3 Wood Fireplace Insert Inserts By Rockford Chimney

Rais 60 Insert Wood Fireplace For

T25i Timberwolf Wood Fireplace Insert Hearth Stove Patio

Breckwell Wood Fireplace Insert Sw180i

What S Best A Fireplace Stove Or Insert We Love Fire

Related Posts