Understanding Fireplace Flue Damper Parts: A Comprehensive Guide

The efficiency and safety of a fireplace depend significantly on a properly functioning flue damper. Understanding the various parts of a fireplace flue damper, their functions, and potential issues is crucial for homeowners who utilize their fireplaces regularly or occasionally. This comprehensive guide will delve into the components of a typical fireplace flue damper, exploring their purpose and how they contribute to overall fireplace performance.

What is a Fireplace Flue Damper?

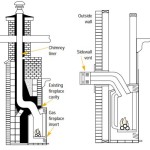

A fireplace flue damper is a movable plate or valve located within the chimney flue. Its primary function is to regulate airflow through the chimney. When the fireplace is in use, the damper is opened to allow combustion byproducts, such as smoke and carbon monoxide, to escape safely. Conversely, when the fireplace is not in use, the damper is closed to prevent heat loss from the home during winter and to deter warm air entry during summer. A properly sealed damper also prevents drafts, keeps out rain and pests, and reduces energy consumption.

Common Fireplace Flue Damper Types

There are two main types of fireplace flue dampers: throat dampers and top-sealing dampers. Each type has different components and operational characteristics. Understanding the difference is crucial when identifying parts and troubleshooting issues.

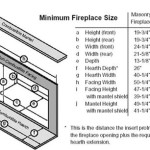

Throat Damper: A throat damper is installed just above the firebox, within the throat of the fireplace. This is the most traditional and common type. It typically consists of a metal plate hinged on either side and controlled by a lever or poker. Its proximity to the firebox makes it effective at quickly sealing off the chimney when the fire is extinguished.

Top-Sealing Damper: A top-sealing damper (also called a chimney top damper) is installed at the top of the chimney. This type often offers a tighter seal compared to throat dampers, reducing heat loss and preventing drafts more effectively. It typically consists of a spring-loaded or gasketed lid that is opened and closed using a cable that runs down the chimney. Top-sealing dampers are generally more expensive to install but can offer long-term energy savings.

Key Parts of a Throat Damper and Their Functions

Throat dampers are the most common type found in older homes. They have several key parts that work together to control airflow. A detailed understanding of these parts is crucial for maintenance and repair.

Damper Plate: This is the main component of the throat damper. It's a flat metal plate, usually made of cast iron or steel, that pivots to open or close the flue. The plate's size and shape are designed to completely block the flue opening when closed.

Pivot Points/Hinges: The damper plate is attached to the fireplace firebox or chimney throat using pivot points or hinges. These allow the plate to swing open and closed. The integrity of these hinges is essential for proper damper function. Rust or corrosion can cause the hinges to seize, making it difficult or impossible to operate the damper.

Damper Frame: The damper plate sits within a frame, typically made of cast iron or steel, that is embedded in the chimney throat. The frame provides a secure mounting point for the damper plate and ensures a tight seal when the plate is closed. Cracks or deterioration in the frame can compromise the damper's ability to seal effectively.

Control Lever/Poker: This is the mechanism used to open and close the damper plate. It is typically a metal lever or rod that extends from the damper plate to the front of the fireplace. The lever allows the user to adjust the damper position manually. In some older models, a poker – a long metal rod – is used to engage with a slot in the damper plate to move it.

Locking Mechanism (Optional): Some throat dampers have a locking mechanism that allows the damper to be secured in either the open or closed position. This can be particularly useful in preventing drafts or ensuring the damper remains open during a fire. However, ensure this locking mechanism is disengaged before starting a fire.

Key Parts of a Top-Sealing Damper and Their Functions

Top-sealing dampers, while typically more expensive, offer enhanced sealing and energy efficiency. Their components differ significantly from throat dampers.

Damper Lid: The damper lid is the main component of a top-sealing damper. It's a metal or composite lid that sits on top of the chimney flue. When closed, it forms a tight seal, preventing air leakage. The lid is designed to withstand harsh weather conditions and temperature fluctuations.

Gasket: A crucial component of a top-sealing damper is the gasket. This rubber or silicone seal is positioned around the perimeter of the damper lid. When the lid is closed, the gasket compresses against the chimney flue, creating an airtight seal. The gasket is essential for preventing heat loss and drafts. Over time, the gasket can deteriorate due to exposure to the elements and high temperatures, requiring replacement.

Spring Assembly: Many top-sealing dampers utilize a spring assembly to help maintain pressure and ensure a tight seal between the lid and the chimney flue. The spring applies consistent force, keeping the lid firmly closed even in windy conditions. The spring’s integrity is important for the damper's effectiveness.

Cable and Handle: Top-sealing dampers are operated using a cable that runs down the chimney flue to a handle located near the fireplace. The cable is usually made of stainless steel to resist corrosion. Pulling the handle opens the damper lid, while releasing the handle allows the lid to close. Regularly inspect the cable for fraying or damage.

Mounting Hardware: The entire top-sealing damper assembly is secured to the top of the chimney using various mounting hardware, including bolts, screws, and brackets. Proper installation and secure mounting are essential to prevent the damper from shifting or becoming dislodged. Inspect the mounting hardware periodically for rust or looseness.

Potential Issues with Fireplace Flue Dampers

Several issues can arise with fireplace flue dampers, affecting their functionality and potentially causing safety hazards. Regular inspection and maintenance are crucial for identifying and addressing these problems.

Rust and Corrosion: Metal damper parts, especially those made of cast iron or steel, are susceptible to rust and corrosion due to exposure to moisture and combustion byproducts. Rust can weaken the damper plate, hinges, and frame, making it difficult to operate the damper or preventing it from sealing properly. Regular cleaning and application of a rust-inhibiting coating can help prevent corrosion.

Debris Accumulation: Soot, creosote, and other debris can accumulate in the damper area, obstructing its movement and preventing a tight seal. This buildup can also increase the risk of chimney fires. Regular chimney sweeping and damper cleaning are essential for removing debris.

Warped or Cracked Damper Plate: Over time, the damper plate can become warped or cracked due to exposure to high temperatures. This can prevent the damper from sealing properly, leading to heat loss and drafts. A severely warped or cracked damper plate may need to be replaced.

Sticking or Seized Hinges: Rust and corrosion can cause the damper hinges to stick or seize, making it difficult or impossible to open and close the damper. Lubricating the hinges with a heat-resistant lubricant can help prevent this problem. If the hinges are severely seized, they may need to be replaced.

Damaged Gasket (Top-Sealing Dampers): The gasket on a top-sealing damper can deteriorate over time due to exposure to the elements and high temperatures. A damaged gasket will compromise the damper's ability to seal effectively, leading to heat loss and drafts. Replacing the gasket is a relatively simple repair that can significantly improve the damper's performance.

Broken or Frayed Cable (Top-Sealing Dampers): The cable that operates a top-sealing damper can become broken or frayed over time, making it difficult or impossible to open and close the damper. Replacing the cable is typically a straightforward repair that can restore the damper's functionality.

Maintenance and Repair Tips

Regular maintenance and timely repairs can extend the lifespan of a fireplace flue damper and ensure its proper functioning. Here are some useful tips:

Regular Inspection: Inspect the damper regularly, ideally before each heating season. Check for rust, corrosion, debris accumulation, and any signs of damage.

Professional Chimney Sweeping: Schedule a professional chimney sweeping at least once a year to remove soot, creosote, and other debris from the chimney and damper area.

Lubrication: Lubricate the damper hinges with a heat-resistant lubricant to prevent sticking and seizing.

Gasket Replacement (Top-Sealing Dampers): Inspect the gasket on a top-sealing damper regularly and replace it if it shows signs of wear or damage.

Cable Replacement (Top-Sealing Dampers): Inspect the cable on a top-sealing damper regularly and replace it if it is frayed or damaged.

Professional Repair: If you are not comfortable performing damper repairs yourself, consult a qualified chimney sweep or fireplace technician. They can diagnose the problem and perform the necessary repairs safely and effectively.

Safety Considerations

Working with fireplace flue dampers involves potential safety hazards. It is important to take necessary precautions to protect yourself and prevent accidents.

Ensure the Fire is Completely Out: Before inspecting or working on a damper, ensure that the fire is completely extinguished and the fireplace has cooled down completely.

Wear Protective Gear: Wear gloves and eye protection to prevent contact with soot, creosote, and other debris.

Work in a Well-Ventilated Area: When cleaning the damper area, work in a well-ventilated area to avoid inhaling harmful fumes or dust.

Follow Manufacturer's Instructions: When replacing damper parts, follow the manufacturer's instructions carefully.

Consult a Professional: If you are unsure about any aspect of damper maintenance or repair, consult a qualified chimney sweep or fireplace technician.

The Purpose Of Your Chimney Damper Asheville Nc Environmental

Flue Vs Damper Explained Fireplace Tips

Fireplace Damper Repair Full Service Chimney Kansas City

Fireplace Dampers Throat Vs Top Mount Swede Chimney Sweep Dryer Vent Cleaning

Fireplace Damper Repair Full Service Chimney Kansas City

Fireplace Dampers The Blog At Fireplacemall

How To Use A Fireplace Damper The Right Way

How To Fix A Stuck Fireplace Damper The Blog At Fireplacemall

What Is A Chimney Damper Full Service

Fireplace Dampers Cast Iron Marshall Stamping

Related Posts