Natural Gas Fireplace Burner Pans: Understanding the Heart of Your Fire

Natural gas fireplaces offer a convenient and aesthetically pleasing alternative to traditional wood-burning fireplaces. At the core of this convenience lies the burner pan, a critical component responsible for distributing the gas and creating the mesmerizing flames that define the fireplace experience. Understanding the function, types, maintenance, and potential issues associated with natural gas fireplace burner pans is essential for safe and efficient operation.

The burner pan serves as the foundation upon which the visual appeal of a natural gas fireplace is built. Its primary function is to evenly distribute natural gas across a specific area, allowing for consistent and controlled combustion. This controlled combustion translates into a balanced and aesthetically pleasing flame pattern, contributing significantly to the overall ambiance of the room. The design and material composition of the burner pan directly influence the flame's height, color, and overall distribution within the firebox.

Beyond aesthetics, the burner pan plays a crucial role in the safety and efficiency of the fireplace. Proper gas distribution ensures complete combustion, minimizing the production of harmful byproducts like carbon monoxide. A well-maintained burner pan also contributes to energy efficiency by optimizing the heat output from the natural gas.

Types of Natural Gas Fireplace Burner Pans

Burner pans are manufactured in various shapes, sizes, and materials, each designed to achieve specific flame patterns and heat outputs. Understanding these different types is crucial when selecting a replacement or troubleshooting performance issues.

Firstly, there are linear burner pans. Linear burner pans, as the name suggests, are characterized by their elongated, rectangular shape. They are commonly found in modern fireplaces and are designed to produce a long, continuous flame. These pans are often made from stainless steel and feature evenly spaced gas ports along their length. The linear design provides a contemporary aesthetic and is well-suited for creating a dramatic visual effect. The consistent flame distribution creates a uniform heat output across the fireplace opening.

Then we have H-burners. H-burners are named for their distinctive H-shaped design. They are typically used in larger fireplaces and offer a broader flame pattern compared to linear burners. The H-shape allows for gas distribution across a wider surface area, resulting in a more substantial and visually impressive flame. H-burners are often constructed from heavy-duty materials to withstand the higher heat output associated with their larger size.

There are also ribbon burners. Ribbon burners feature a narrow slit or ribbon-like opening through which the gas is released. This design creates a delicate and flickering flame, often preferred for its realistic wood-burning appearance. Ribbon burners are typically used in smaller fireplaces or decorative inserts. The subtle flame pattern is ideal for creating a cozy and intimate atmosphere.

Finally, we have pan burners, which are more basic. Pan burners are the simplest type of burner pan, typically consisting of a shallow pan with a series of gas ports drilled into the surface. They are often found in older fireplaces or budget-friendly models. Pan burners produce a more scattered and less uniform flame pattern compared to other types. While less aesthetically pleasing, they offer a cost-effective solution for basic fireplace functionality.

The choice of burner pan depends on several factors, including the size and style of the fireplace, the desired flame pattern, and the budget. Consulting with a qualified fireplace technician is recommended to ensure the correct type of burner pan is selected for optimal performance and safety.

Materials Used in Burner Pan Construction

The materials used in the construction of a burner pan significantly impact its durability, heat resistance, and overall performance. Common materials include stainless steel, cast iron, and aluminized steel. Each material offers distinct advantages and disadvantages.

Stainless steel is a popular choice for burner pans due to its excellent corrosion resistance and high heat tolerance. Stainless steel burner pans are resistant to rust and degradation, even under prolonged exposure to high temperatures and moisture. This makes them a durable and long-lasting option. However, stainless steel burner pans can be more expensive than those made from other materials. The cost is offset by their extended lifespan and resistance to corrosion.

Cast iron burner pans are known for their exceptional heat retention capabilities. Cast iron absorbs and radiates heat evenly, contributing to a consistent and comfortable warmth in the room. However, cast iron is more susceptible to rust and corrosion compared to stainless steel. Regular maintenance and protective coatings are necessary to prevent deterioration. The weight of cast iron can also make installation and maintenance more challenging.

Aluminized steel offers a cost-effective alternative to stainless steel and cast iron. Aluminized steel is steel coated with a layer of aluminum, providing some degree of corrosion resistance. However, aluminized steel is not as durable as stainless steel and may be more prone to rust over time, particularly in humid environments. It is a budget-friendly option, but may require more frequent replacement compared to stainless steel burner pans.

The selection of the appropriate material depends on factors such as budget, climate conditions, and desired lifespan. Stainless steel provides the best combination of durability and corrosion resistance, while cast iron offers superior heat retention. Aluminized steel provides a more affordable option for less demanding applications.

Maintaining Your Natural Gas Fireplace Burner Pan

Regular maintenance of the burner pan is crucial for ensuring safe and efficient operation of the natural gas fireplace. Neglecting maintenance can lead to performance issues, safety hazards, and reduced lifespan of the burner pan. This routine maintenance involves cleaning, inspection, and occasional replacement of worn components.

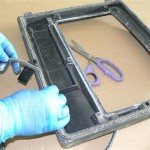

Cleaning the burner pan is essential for removing debris, dust, and soot that can accumulate over time. These deposits can obstruct gas flow, leading to uneven flame patterns and reduced heat output. Before cleaning, ensure the gas supply to the fireplace is turned off and the unit has cooled completely. Use a soft brush or vacuum cleaner to remove loose debris from the burner pan and gas ports. For more stubborn deposits, a mild detergent and warm water solution can be used. Avoid using abrasive cleaners or scouring pads, as they can damage the burner pan's surface. Thoroughly dry the burner pan before reassembling the fireplace.

Periodic inspection of the burner pan is also essential for identifying signs of wear, corrosion, or damage. Check for cracks, rust, or warping of the metal. Inspect the gas ports for clogs or obstructions. If any damage is detected, the burner pan should be replaced immediately. Ignoring these issues can lead to gas leaks, inefficient combustion, and potential safety hazards. A professional fireplace technician can perform a thorough inspection and recommend appropriate repairs or replacements.

Keep an eye for unusual flame colors. The color of the flame can indicate potential problems with the gas supply or burner pan. A yellow or orange flame may indicate incomplete combustion, which can produce carbon monoxide. A blue flame is generally considered normal and indicates complete combustion. If the flame color is unusual, consult with a qualified technician to diagnose and resolve the issue.

The lifespan of a burner pan varies depending on the material, usage, and maintenance. However, even with proper care, burner pans will eventually need to be replaced. Signs that a burner pan needs replacement include significant rust or corrosion, cracks or warping, and persistent uneven flame patterns. Replacing a burner pan is a relatively straightforward process, but it is recommended to consult with a qualified technician to ensure proper installation and safety.

By following a regular maintenance schedule, homeowners can extend the lifespan of their natural gas fireplace burner pan and enjoy safe, efficient, and aesthetically pleasing fires for years to come. Proper maintenance not only ensures optimal performance but also minimizes the risk of potential hazards and costly repairs.

Rasmussen Cs Custom Pan Vented Fireplace Burner Kit With Strap Legs

Vevor Drop In Fire Pit Pan 31 Round Burner 300 K Btu Stainless Steel Gas For Keeping Warm Yxskhpqrs31in0efev0 The Home Depot

Aspen Industries Master Flame Natural Gas Fireplace Sand Burner

Burner Styles Rasmussen Gas Logs

Stanbroil 18 Inch Natural Gas Powder Coated Steel Fireplace Triple Flame Pan Burner Kit Outdoor

Hpc Fire Drop In Pit Burner Pan Linear Trough Included

How Do I Build A Diy Fire Pit For Natural Gas Starfire Direct

Vevor Drop In Fire Pit Pan 31 Round Burner 300 K Btu Stainless Steel Gas For Keeping Warm Yxskhpqrs31in0efev0 The Home Depot

Rasmussen Fx Flaming Ember Xtra Vented Fireplace Burner Kit

Stainless Steel Gas Fireplace Burner Pan Magic Touch Mechanical

Related Posts