Propane Fireplace Regulator Troubleshooting: A Comprehensive Guide

Propane fireplaces offer a convenient and efficient heating solution for many homes. These appliances rely on a propane regulator to manage the pressure of the propane gas flowing from the tank to the burner. A malfunctioning regulator can lead to various issues, including insufficient flame, inconsistent heat, or even a complete lack of operation. Understanding the function of a propane regulator and mastering basic troubleshooting techniques can save time and money by potentially resolving the problem without the need for professional assistance. This article provides a detailed guide to diagnosing and addressing common issues with propane fireplace regulators.

A propane regulator serves as a pressure-reducing valve, decreasing the high pressure from the propane tank (typically between 100-200 PSI) to a lower, more manageable pressure suitable for the fireplace burner (usually around 11 inches of water column, or 0.4 PSI). This precise pressure control is crucial for safe and efficient combustion. There are typically two types of regulators used in propane fireplace systems: single-stage and two-stage. Single-stage regulators reduce the tank pressure to the burner pressure in a single step. Two-stage regulators first reduce the tank pressure to an intermediate level before further reducing it to the burner pressure, offering more consistent pressure regulation, particularly when tank pressure fluctuates.

Before attempting any troubleshooting, it is imperative to prioritize safety. Always turn off the propane supply at the tank valve before inspecting any part of the system. Ensure adequate ventilation to prevent the accumulation of propane gas. Use appropriate tools and wear safety gloves. If you are uncomfortable performing any task, contact a qualified gas technician.

Key Point 1: Identifying Symptoms of a Malfunctioning Regulator

Recognizing the symptoms of a faulty propane regulator is the first step in effective troubleshooting. Common indicators include:

*Low Flame or Insufficient Heat:

If the fireplace flame is significantly smaller than usual or the unit is not producing adequate heat, the regulator might not be delivering enough propane. This can be caused by a blocked vent, internal damage, or a failure to maintain consistent pressure. *Inconsistent Flame Height:

A fluctuating flame height, where the flame surges and dips erratically, can indicate an unstable pressure output from the regulator. This instability can be caused by internal wear or debris interfering with the regulator's mechanism. *Pilot Light Issues:

Difficulty lighting or maintaining the pilot light can also point to a regulator problem. If the pilot light repeatedly goes out or is very weak, the regulator may not be providing sufficient gas flow to sustain it. *Propane Odor:

A strong smell of propane, especially near the regulator, could indicate a leak. While not always directly caused by the regulator itself (it could be a connection issue), it's crucial to investigate any propane odor immediately and shut off the gas supply until the source is identified and resolved. *Complete Fireplace Failure:

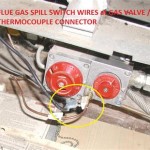

If the fireplace fails to ignite at all, even after attempting to light the pilot light, a completely malfunctioning regulator could be the culprit. This could be due to a complete blockage or failure of the internal components of the regulator.Often, these symptoms can be attributed to other factors, such as a clogged burner or a faulty thermocouple. Therefore, it is important to perform a systematic check of all components before concluding that the regulator is the source of the problem.

Key Point 2: Initial Inspection and Basic Checks

Before delving into more complex troubleshooting steps, conduct a thorough visual inspection and perform some basic checks:

*Visual Inspection:

Carefully examine the regulator for any signs of physical damage, such as cracks, dents, or corrosion. Check the vent on the regulator for any obstructions, such as dirt, debris, or insect nests. The vent is crucial for equalizing pressure and allowing the regulator to function properly. *Connection Check:

Inspect all connections between the regulator, the propane tank, and the fireplace gas valve. Ensure that all fittings are tight and secure. Use a soapy water solution to check for leaks at the connections. Apply the solution to the fittings and look for bubbles, which indicate a gas leak. If a leak is detected, tighten the fitting or replace it if necessary. *Hose Inspection:

Examine the propane hose for any signs of damage, such as cracks, kinks, or abrasions. A damaged hose can restrict gas flow or leak propane. If the hose is damaged, it must be replaced immediately. *Tank Level:

Ensure that the propane tank is not empty or running low. A low tank level can cause inconsistent pressure and affect the fireplace's performance. If the tank is low, refill it and re-test the fireplace. *Regulator Orientation:

Verify that the regulator is installed in the correct orientation. Most regulators have an arrow indicating the direction of gas flow. Ensure that the arrow points towards the fireplace.These initial checks can often reveal simple problems that are easily corrected. If these checks do not resolve the issue, further troubleshooting may be required.

Key Point 3: Advanced Troubleshooting Techniques

If the initial inspection and basic checks do not identify the problem, more advanced troubleshooting techniques may be necessary. These techniques often involve using specialized tools and a deeper understanding of the regulator's operation. Caution should be exercised when performing these steps.

*Pressure Testing:

Use a manometer to measure the outlet pressure of the regulator. Connect the manometer to a test port on the fireplace gas valve or directly to the regulator outlet. With the fireplace operating, observe the pressure reading. The pressure should be within the manufacturer's specified range, typically around 11 inches of water column (WC). If the pressure is significantly outside this range (too high or too low), the regulator is likely faulty and needs to be replaced. *Lock-Up Pressure Test:

This test assesses the regulator's ability to shut off the gas flow when there is no demand. Close the fireplace gas valve and observe the manometer reading. The pressure should remain stable. If the pressure slowly increases, it indicates that the regulator is leaking and not shutting off properly. This is a serious safety concern and requires immediate attention. Replacement of the regulator is necessary. *Droop Test:

This test evaluates the regulator's ability to maintain a consistent pressure under load. Start the fireplace and, while it is operating, monitor the manometer reading. Observe how the pressure changes as the fireplace cycles on and off. A healthy regulator should maintain a relatively stable pressure. If the pressure drops significantly when the fireplace is running and then rises when it shuts off, it suggests that the regulator is struggling to maintain a consistent output. *Vent Inspection and Cleaning:

A blocked regulator vent can significantly impact its performance. Use a small wire or compressed air to carefully clear any obstructions from the vent. Be gentle to avoid damaging the vent screen or internal components. After cleaning the vent, re-test the regulator's operation. *Internal Inspection (If Possible and Safe):

Some regulators can be partially disassembled for internal inspection. However, this should only be attempted if you are comfortable working with gas appliances and have the necessary expertise. Look for signs of corrosion, debris, or damaged components inside the regulator. If any damage is found, the regulator should be replaced.Important:

Disassembling a regulator can void any warranty and may compromise its safety if not done correctly.It is crucial to note that some propane regulators are not designed to be repaired and must be replaced if they malfunction. Attempting to repair a regulator that is not designed for repair can be dangerous and could lead to gas leaks or explosions.

When dealing with propane systems, safety is paramount. If at any point you feel uncomfortable or unsure about performing a troubleshooting step, it is best to consult a qualified gas technician. A professional has the expertise and tools to accurately diagnose and repair propane fireplace regulator issues safely and effectively. Furthermore, it’s important to regularly schedule professional maintenance for your propane fireplace to ensure optimal performance and safety.

How To Tell If The Propane Gas Regulator A Burner Or Grill Is Bad Problems

5 Signs You Need A New Regulator On Propane System Tarantin Industries

Propane Problems How To Spot A Bad Regulator Diy Fixes When Safe Boatbasincafe

How To Test Your Main Control Valve Www Mygasfireplacerepair Com

Propane Problems How To Spot A Bad Regulator Diy Fixes When Safe Boatbasincafe

Propane Problems How To Spot A Bad Regulator Diy Fixes When Safe Boatbasincafe

How To Tell If The Propane Gas Regulator A Burner Or Grill Is Bad Problems

Trouble Shooting Guide Gas Regulator

My Gas Fireplace Pilot Light Works Perfectly However When I Flip The Switch For Rest Of To Turn On Nothing Happens What Quora

How To Adjust Gas Pressure Regulator Tutorial Diy Windy City Restaurant Equipment Parts

Related Posts