Direct Vent Gas Fireplace Venting: A Comprehensive Guide

Direct vent gas fireplaces have become increasingly popular due to their efficiency, ease of use, and versatility in installation. A crucial component of any direct vent fireplace system is the venting system, which is responsible for safely removing combustion byproducts from the home while simultaneously drawing in fresh air for combustion. Understanding the principles of direct vent gas fireplace venting is essential for ensuring safe and efficient operation. This article will delve into the specifics of direct vent technology, the different types of venting systems and their installation requirements, and provide guidance on troubleshooting common venting issues.

Understanding Direct Vent Technology

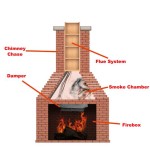

Direct vent fireplaces differ significantly from traditional wood-burning fireplaces and even some other types of gas fireplaces. The defining characteristic of direct vent systems is their sealed combustion chamber. This sealed chamber separates the fireplace from the interior environment of the home. Unlike traditional fireplaces, which draw air from the room for combustion, direct vent fireplaces utilize a coaxial or concentric venting system. This system consists of two pipes, one inside the other or side-by-side. The inner pipe expels exhaust gases to the outside, while the outer pipe draws fresh air from the outside into the firebox for combustion. This process creates a closed-loop system that minimizes the risk of backdrafting and reduces heat loss from the home.

The sealed combustion chamber and direct vent system offer several advantages. First, they enhance safety by preventing the leakage of harmful gases, such as carbon monoxide, into the living space. Second, they improve energy efficiency by eliminating the need to draw heated air from the room for combustion, thereby reducing drafts and minimizing heat loss. Third, they provide greater installation flexibility, as direct vent fireplaces can be vented horizontally through an exterior wall or vertically through the roof. This allows for installation in a wider range of locations within a home, including rooms without existing chimneys.

Furthermore, direct vent fireplaces often feature advanced control systems and safety features, such as automatic shut-off mechanisms and electronic ignition. These features contribute to the overall safety and convenience of using a direct vent gas fireplace.

Types of Direct Vent Systems and Installation Requirements

Several different types of direct vent systems are available, each with its own specific installation requirements. The two primary types are coaxial and co-linear systems. Coaxial direct vent systems utilize a single pipe with two concentric channels. The inner channel carries exhaust gases, while the outer channel draws in fresh air. Co-linear systems, on the other hand, use two separate pipes positioned side-by-side, one for exhaust and one for intake.

Installation requirements for direct vent systems are dictated by building codes, manufacturer instructions, and the specific characteristics of the fireplace and venting components. Adhering to these requirements is crucial for ensuring safe and efficient operation. Key considerations include the following:

- Vent Pipe Material: Direct vent systems require specialized vent pipes designed and tested for use with gas appliances. These pipes are typically constructed of aluminum or stainless steel and are specifically listed and labeled for direct vent applications. Using incorrect vent pipe can lead to corrosion, leakage, and potentially dangerous situations.

- Vent Pipe Diameter: The diameter of the vent pipe must match the specifications outlined in the fireplace manufacturer's instructions. Using an undersized vent pipe can restrict airflow and lead to incomplete combustion, while an oversized pipe may not provide adequate draft.

- Vent Pipe Length and Configuration: The maximum and minimum vent pipe lengths are specified by the manufacturer and must be strictly adhered to. Exceeding the maximum length can reduce draft and increase the risk of condensation buildup, while using a vent pipe that is too short may not provide adequate separation between the exhaust and intake. Furthermore, the number and type of elbows or bends in the vent pipe affect the overall performance of the system. Each elbow adds resistance to airflow, and excessive elbows can negatively impact draft.

- Terminations: The termination point of the vent pipe, where the exhaust gases are expelled to the outside, must be located in accordance with building codes and manufacturer instructions. This typically involves maintaining specific clearances from windows, doors, air inlets, and other building features to prevent the re-entry of exhaust gases into the home. The type of vent termination cap is also important to prevent rain or snow from entering the venting system.

- Clearances to Combustibles: Maintaining proper clearances to combustible materials, such as wood framing, insulation, and drywall, is essential for preventing fire hazards. The fireplace and vent pipes must be installed with the minimum clearances specified by the manufacturer.

- Sealing and Support: All vent pipe joints must be properly sealed with high-temperature sealant to prevent leaks. The vent pipe must also be adequately supported to prevent sagging or movement, which could compromise the integrity of the system.

Professional installation by a qualified technician is strongly recommended to ensure that the direct vent system is installed correctly and in compliance with all applicable codes and regulations. A professional installer will have the knowledge and experience to properly size the vent pipe, select the appropriate termination location, and ensure that all clearances and sealing requirements are met.

Troubleshooting Common Venting Issues

Even with proper installation, problems can occasionally arise with direct vent gas fireplace venting systems. Recognizing the symptoms of common venting issues and understanding their potential causes is crucial for maintaining safe and efficient operation. Some common problems include:

- Soot Buildup: Excessive soot buildup on the glass or within the firebox can indicate incomplete combustion, often caused by insufficient airflow or a malfunctioning gas valve. Checking and cleaning the burner assembly, inspecting the vent pipe for obstructions, and ensuring proper gas pressure are important steps in addressing soot buildup.

- Pilot Light Issues: Difficulty lighting or maintaining the pilot light can be caused by a dirty pilot assembly, a weak thermocouple, or insufficient gas pressure. Cleaning the pilot assembly and replacing the thermocouple are common troubleshooting steps. If the problem persists, a qualified technician should inspect the gas valve and gas supply.

- Condensation: Condensation inside the vent pipe can occur when the exhaust gases cool too quickly, particularly in cold climates. This can be mitigated by ensuring that the vent pipe is properly insulated and that the vent pipe length is within the manufacturer's recommended range. In some cases, a vent restrictor may be necessary to reduce airflow and maintain higher exhaust gas temperatures.

- Backdrafting: Backdrafting, where exhaust gases enter the home instead of being expelled to the outside, is a serious safety hazard. This can be caused by obstructions in the vent pipe, negative pressure within the home, or a malfunctioning draft inducer fan. Addressing backdrafting requires a thorough inspection of the venting system and the home's ventilation to identify and correct the underlying cause.

- Unusual Noises: Whistling or rattling noises emanating from the vent pipe can indicate loose connections, obstructions, or excessive airflow. Inspecting the vent pipe for loose connections and removing any obstructions are important troubleshooting steps.

When troubleshooting venting issues, it is essential to prioritize safety. If you suspect a gas leak or carbon monoxide exposure, immediately evacuate the premises and contact your local fire department or gas company. For complex or persistent problems, consulting a qualified HVAC technician or gas fireplace specialist is highly recommended. Regular maintenance, including cleaning the firebox, inspecting the vent pipe, and checking the burner assembly, can help prevent many common venting issues and ensure the continued safe and efficient operation of your direct vent gas fireplace.

Proper maintenance should also include regular carbon monoxide detector checks. Ensure that carbon monoxide detectors are properly placed and are functioning correctly. Carbon monoxide detectors are an essential safety measure for any home with a gas fireplace.

Also it is important to keep the area around the fireplace clear from obstructions such as furniture and draperies to ensure proper air circulation and prevent potential fire hazards. Following these guidelines will help maintain a safe and enjoyable fireplace experience.

In summary, direct vent gas fireplace venting is a critical aspect of ensuring safe and efficient operation. By understanding the principles of direct vent technology, adhering to installation requirements, and promptly addressing potential venting issues, homeowners can enjoy the benefits of a direct vent fireplace while minimizing risks. Always consult with qualified professionals for installation and maintenance to guarantee the safety and longevity of the system.

Gas Fireplace Venting Explained Heat Glo

Gas Fireplace Venting Explained Heat Glo

What Are The Best Ways To Vent A Gas Fireplace Zoroast

Vented Vs B Vent Direct Free Dixie S

Direct Vent Vs Natural Www Mygasfireplacerepair Com

What Is A Direct Vent Fireplace Fireplaces Learning Center

Regency Flex Vent Kit Cap Thimble 4 7 946 516

.aspx?strip=all)

Benefits Of Direct Vent Fireplaces Regency Fireplace S

Icc Direct Vent Gas Venting Elbows 4 7 5 8 Friendlyfires Ca

Fireplace Cover To Keep Cold Air Out

Related Posts