The article should include information about safety precautions to take, and supplies to acquire. ## Can You Paint a Metal Fireplace Surround? A Comprehensive Guide

A metal fireplace surround can significantly influence the aesthetic of a living space. Over time, it may become outdated, chipped, or simply no longer align with the desired décor. Instead of replacing the entire surround, painting offers a cost-effective and relatively simple way to refresh its appearance. However, successful painting of a metal fireplace surround requires careful preparation, the selection of appropriate materials, and adherence to specific safety precautions. This article provides a detailed guide to help ensure a professional and long-lasting finish when painting a metal fireplace surround.

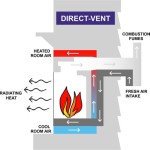

Before embarking on this project, it is crucial to understand the inherent challenges and potential risks involved. Metal surfaces require specialized primers and paints to ensure proper adhesion and prevent rust. Moreover, a fireplace surround is exposed to heat, necessitating heat-resistant paints that can withstand high temperatures without cracking, blistering, or emitting harmful fumes. Ignoring these factors can result in a subpar finish, potential safety hazards, and a waste of time and resources.

Key Point 1: Preparation is Paramount

Proper preparation is arguably the most critical step in painting any surface, and a metal fireplace surround is no exception. This stage involves thoroughly cleaning the surface, removing any rust or loose paint, and creating a suitable base for the new paint to adhere to. Neglecting these steps will almost certainly lead to peeling, blistering, and an overall unsatisfactory finish.

The first step is to thoroughly clean the metal surround. Use a degreasing cleaner specifically designed for metal surfaces to remove any dirt, grime, soot, or grease buildup. Apply the cleaner according to the manufacturer's instructions and scrub the surface with a stiff brush or sponge. Rinse thoroughly with clean water and allow it to dry completely. Avoid using abrasive cleaners that may scratch the surface.

Next, inspect the surround for any signs of rust or loose paint. Rust can be removed using a wire brush, sandpaper, or a chemical rust remover. For minor rust spots, a wire brush or sandpaper may suffice. Rub the affected areas vigorously until the rust is completely removed. For more extensive rust damage, a chemical rust remover may be necessary. Follow the manufacturer's instructions carefully when using chemical rust removers, and ensure adequate ventilation. Protect your skin and eyes by wearing gloves and safety glasses.

Loose or peeling paint should also be removed. Use a paint scraper or a wire brush to gently remove any loose paint flakes. If the old paint is particularly stubborn, you may need to use a paint stripper. Apply the paint stripper according to the manufacturer's instructions and allow it to sit for the recommended amount of time. Then, scrape off the softened paint with a paint scraper. Be sure to wear appropriate protective gear when using paint strippers, as they can be corrosive.

Once the surface is clean and free of rust and loose paint, it is time to sand it. Sanding creates a slightly rough surface that will allow the primer to adhere better. Use a medium-grit sandpaper (around 120-grit) to sand the entire surface of the surround. Pay particular attention to areas where you have removed rust or paint. After sanding, wipe down the surface with a tack cloth to remove any sanding dust. This is crucial for a smooth finish.

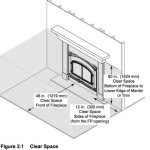

Finally, masking is essential to protect surrounding areas from paint splatter. Use painter's tape and drop cloths to cover the surrounding wall, floor, and any other surfaces that you do not want to paint. Ensure the tape is firmly pressed down to prevent paint from seeping underneath.

Key Point 2: Selecting the Right Products

Choosing the right primer and paint is crucial for achieving a durable and aesthetically pleasing finish on a metal fireplace surround. Not all primers and paints are created equal, and using the wrong products can lead to poor adhesion, premature failure, and potentially hazardous fumes. It is imperative to select products specifically designed for high-heat applications and metal surfaces.

Primer is a critical component of the painting process. It provides a bonding layer between the metal surface and the paint, ensuring proper adhesion and preventing rust. For metal fireplace surrounds, a high-quality, rust-inhibiting primer specifically formulated for metal is essential. Look for primers that are designed to withstand high temperatures. Apply the primer according to the manufacturer's instructions, using a brush, roller, or spray gun. Allow the primer to dry completely before applying the paint.

The choice of paint is equally important. Regular paints are not suitable for fireplace surrounds, as they cannot withstand the high temperatures and may emit harmful fumes when heated. High-heat paints, typically designed for stoves, grills, and other high-temperature applications, are the only appropriate option. These paints are formulated to resist cracking, blistering, and peeling under extreme heat conditions. They are also designed to be non-toxic when heated, ensuring the safety of the occupants of the room.

High-heat paints are available in various finishes, including matte, satin, and gloss. Choose a finish that complements the overall aesthetic of the room. Consider the ease of cleaning when selecting a finish. Matte finishes tend to be more porous and may be more difficult to clean than satin or gloss finishes. High-heat paints are also available in a wide range of colors. Select a color that complements the existing décor and creates the desired ambiance.

When choosing a paint application method, consider both the size and complexity of the surround. Spray paint offers a smooth, even finish and is particularly well-suited for intricate designs or hard-to-reach areas. However, it requires careful masking and ventilation to prevent overspray. Brush painting is a more controlled method and is ideal for smaller surrounds or when precision is required. However, it may be more difficult to achieve a perfectly smooth finish with brush painting. Roller painting is suitable for large, flat surfaces and can provide a good balance between speed and quality. Be sure to use a roller designed for smooth surfaces to minimize texture.

Key Point 3: Safety Precautions

Painting a metal fireplace surround involves certain safety risks that must be addressed to prevent injury or illness. These risks include exposure to harmful fumes from paints and strippers, potential fire hazards, and physical injuries from tools and equipment. Taking appropriate safety precautions is paramount to ensure a safe and successful painting project.

Ventilation is crucial when working with paints, primers, and strippers. Many of these products contain volatile organic compounds (VOCs) that can be harmful if inhaled. Always work in a well-ventilated area, and consider using a respirator to protect yourself from inhaling harmful fumes. Open windows and doors to allow for fresh air circulation, and use a fan to help dissipate fumes. If you experience any symptoms of exposure, such as dizziness, headache, or nausea, immediately stop working and seek fresh air.

Fire safety is also a major concern. Many paints and strippers are flammable, and improper handling can lead to a fire. Keep all flammable materials away from sources of heat or ignition, such as open flames, sparks, and electrical equipment. Store paints and strippers in a cool, dry place away from direct sunlight and heat. Never smoke or use open flames in the vicinity of paints or strippers. Have a fire extinguisher readily available in case of a fire.

Personal protective equipment (PPE) is essential to protect yourself from exposure to harmful chemicals and physical injuries. Wear gloves to protect your skin from contact with paints, strippers, and cleaning solutions. Wear safety glasses to protect your eyes from splashes and debris. Wear a respirator to protect your lungs from inhaling harmful fumes. Wear appropriate clothing to protect your skin from spills and splatters. Avoid wearing loose clothing that could get caught in tools or equipment.

When working with tools and equipment, follow all safety instructions provided by the manufacturer. Use power tools with caution, and always wear appropriate eye protection. Keep your work area clean and organized to prevent trips and falls. Dispose of waste materials properly, following all local regulations. Never pour paints or strippers down the drain, as they can contaminate the water supply.

Following these safety precautions will help to minimize the risks associated with painting a metal fireplace surround and ensure a safe and successful project. By taking the time to prepare properly, selecting the right products, and prioritizing safety, one can transform the appearance of a fireplace surround and enhance the aesthetic appeal of a living space.

How To Paint Metal Fireplace Surround Four Generations One Roof

How To Spray Paint A Brass Fireplace Insert Erfly House

How To Spray Paint A Brass Fireplace Insert Erfly House

How To Spray Paint A Brass Fireplace Insert Erfly House

How To Paint A Brass Fireplace Screen Addicted 2 Decorating

How To Spray Paint A Brass Fireplace Insert Erfly House

How To Spray Paint A Brass Fireplace Insert Erfly House

Fireplace Makeover Spray Paint Magic

How To Spray Paint A Brass Fireplace Bright Green Door

How To Spray Paint A Brass Fireplace Bright Green Door

Related Posts