Here is an article focusing on gas fireplace chimney vents.

Gas Fireplace Chimney Venting: A Comprehensive Overview

Gas fireplaces offer a convenient and aesthetically pleasing alternative to traditional wood-burning fireplaces. However, proper venting is crucial for the safe and efficient operation of any gas fireplace. The chimney vent system is responsible for removing combustion byproducts, such as carbon dioxide, water vapor, and potentially dangerous carbon monoxide, from the home. Understanding the different types of venting options, their installation requirements, and maintenance considerations is essential for homeowners and professionals alike.

Improper or inadequate venting can lead to serious health risks, including carbon monoxide poisoning, which can be fatal. Furthermore, incorrect venting can also damage the fireplace itself and potentially compromise the structural integrity of the home. Compliance with local building codes and manufacturer specifications is paramount when installing and maintaining a gas fireplace venting system.

Types of Gas Fireplace Venting Systems

Several different types of venting systems are available for gas fireplaces, each with its own set of advantages and disadvantages. The choice of venting system depends on factors such as the fireplace location, the home's construction, and local code requirements.

B-Vent Systems: B-vent systems are among the most common types of venting used for gas fireplaces. These systems utilize double-walled metal pipes that vent vertically through the roof. They rely on natural draft, meaning they depend on the buoyancy of hot gases to rise through the chimney. B-vent systems are typically used for natural gas fireplaces and require a specific chimney design to ensure proper draft. They are generally less expensive to install than direct vent systems but may be more susceptible to backdrafting in certain conditions.

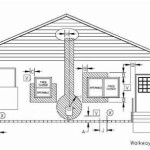

Direct Vent Systems: Direct vent systems are a popular choice for their versatility and safety features. These systems utilize a sealed combustion chamber that draws air from outside the home for combustion and vents exhaust gases directly to the exterior through a coaxial pipe. The coaxial pipe consists of two pipes, one within the other, with the inner pipe carrying exhaust gases and the outer pipe drawing in fresh air. This design prevents combustion air from being drawn from inside the home, minimizing the risk of carbon monoxide poisoning. Direct vent systems can be vented horizontally through a side wall or vertically through the roof, offering greater flexibility in placement. They are generally more expensive than B-vent systems but provide enhanced safety and efficiency.

Vent-Free Systems: Although sometimes marketed as a simple solution, vent-free gas fireplaces are generally discouraged and even prohibited in some jurisdictions due to safety concerns. These systems do not require a chimney or venting system, instead releasing combustion byproducts directly into the room. While equipped with oxygen depletion sensors (ODS) designed to shut off the fireplace if oxygen levels become dangerously low, these sensors are not foolproof. Vent-free fireplaces can contribute to elevated levels of carbon monoxide, nitrogen dioxide, and other pollutants within the home, especially in poorly ventilated spaces. The installation and use of vent-free gas fireplaces should be approached with extreme caution, and local codes should be consulted prior to installation.

Installation Requirements and Considerations

The installation of a gas fireplace venting system must comply with all applicable building codes and manufacturer specifications. Improper installation can lead to serious safety hazards and may void the warranty on the fireplace. It is highly recommended that a qualified and licensed HVAC professional or gas fireplace installer perform the installation.

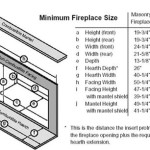

Sizing and Material: The correct sizing of the venting system is critical to ensure proper draft and prevent the buildup of combustion byproducts. The diameter and height of the vent pipe must be determined based on the fireplace's BTU input, the type of fuel used, and the length of the vent run. The vent pipe material must also be compatible with the type of gas fireplace being installed. Typically, B-vent systems use galvanized steel or aluminum vent pipes, while direct vent systems use specialized coaxial pipes.

Clearances and Termination: Proper clearances must be maintained between the vent pipe and combustible materials, such as wood framing, insulation, and roofing materials. Manufacturer specifications typically outline the minimum clearance requirements. The vent termination, whether it is a chimney cap for a B-vent system or a termination cap for a direct vent system, must be located in a safe and accessible location, away from windows, doors, and air intakes. This prevents exhaust gases from re-entering the home or being drawn into the ventilation system.

Inspections: After installation, the venting system should be inspected by a qualified professional to ensure that it is properly installed and functioning correctly. The inspection should include a visual examination of the vent pipe, connections, and termination, as well as a draft test to verify that the system is venting properly. Some jurisdictions require a permit and inspection before a gas fireplace can be used.

Maintenance and Safety

Regular maintenance is essential to ensure the safe and efficient operation of a gas fireplace venting system. Proper maintenance can help prevent blockages, corrosion, and other problems that can compromise the system's performance.

Regular Inspections: Homeowners should visually inspect the venting system at least once a year, looking for signs of damage, corrosion, or blockage. The chimney cap or termination cap should be checked to ensure that it is free of debris, such as leaves, twigs, and bird nests. Any cracks, gaps, or loose connections should be repaired promptly.

Professional Cleaning: It is recommended to have the venting system professionally cleaned every one to three years, depending on the frequency of fireplace use and the type of fuel burned. A professional chimney sweep can remove any accumulated soot, creosote, or other debris from the vent pipe, ensuring proper draft and preventing chimney fires. They can also identify any potential problems with the system and recommend necessary repairs.

Carbon Monoxide Detectors: Carbon monoxide detectors should be installed in the home, near sleeping areas and on each level of the house. These detectors provide an early warning in the event of carbon monoxide buildup, allowing occupants to evacuate the premises safely. The batteries should be tested regularly and replaced as needed. If the carbon monoxide detector alarms, evacuate the house immediately and call the fire department or a qualified HVAC technician.

By understanding the different types of gas fireplace venting systems, their installation requirements, and maintenance considerations, homeowners can ensure the safe and efficient operation of their gas fireplaces for years to come. Prioritizing safety and adhering to local codes and manufacturer specifications are crucial for preventing potential hazards and enjoying the warmth and comfort of a gas fireplace.

Gas Fireplace Venting Explained Heatilator

Venting A Gas Fireplace Through Existing Chimney Design Inserts

Gas Fireplace Venting Explained Heat Glo

Benefits Of Direct Vent Fireplaces

Vented Vs B Vent Direct Free Dixie S

Gas Fireplace Venting Explained Heat Glo

What Are The Best Ways To Vent A Gas Fireplace Zoroast

What Is A Direct Vent Fireplace Fireplaces Learning Center

If You Have A Gas Fireplace It May Or Not Chimney Flue

Fireplace Cover To Keep Cold Air Out

Related Posts