How To Make Your Wood Burning Fireplace More Efficient

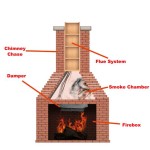

Wood-burning fireplaces, while aesthetically pleasing and creating a cozy ambiance, are notoriously inefficient heating sources. Traditional fireplaces often draw heated air from the home while simultaneously expelling a significant portion of the fire's heat up the chimney. This can lead to increased energy bills and a drafty indoor environment. However, with strategic modifications and informed operational practices, the efficiency of a wood-burning fireplace can be considerably improved.

Several factors contribute to fireplace inefficiency. A primary culprit is the natural draft created by the chimney. This draft continuously pulls air from the room, even when a fire is not burning. This air is replaced by colder air drawn in from outside through cracks and gaps in the building envelope, exacerbating heat loss. Moreover, the open design of a traditional fireplace allows a significant amount of heat to escape directly up the chimney, often exceeding 80% of the generated heat. This inefficiency is compounded by incomplete combustion, which results in the release of unburned gases and particulate matter, further reducing the fire's heat output and contributing to air pollution.

Addressing these challenges requires a multifaceted approach that encompasses fireplace design, fuel selection, and operational techniques. Implementing specific modifications and adhering to best practices can significantly enhance the heat output and overall efficiency of a wood-burning fireplace, leading to a more comfortable and cost-effective heating experience.

Improving Fireplace Design and Components

One of the most impactful strategies for improving fireplace efficiency involves modifications to the fireplace's structure and incorporated components. These modifications aim to reduce heat loss, improve combustion efficiency, and redirect heat into the living space.

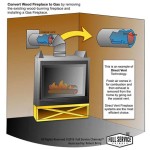

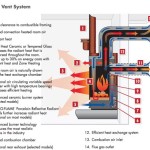

A significant improvement can be achieved by installing a fireplace insert. A fireplace insert is a closed combustion appliance that is installed directly into the existing fireplace opening. These inserts are typically constructed from cast iron or steel and feature a tightly sealed firebox and a controlled air intake system. The closed design minimizes air leakage and improves combustion efficiency. Furthermore, many fireplace inserts are equipped with a blower fan that circulates heated air into the room, significantly enhancing heat distribution. Inserts are available in various sizes and heat output ratings to suit different fireplace dimensions and heating requirements. By providing a controlled combustion environment and actively distributing heat, fireplace inserts offer a substantial improvement over traditional open fireplaces.

Another way to enhance efficiency is through the installation of glass doors. Fireplace glass doors serve multiple purposes. They reduce the amount of air drawn from the room, minimizing heat loss due to chimney draft. They also help to contain sparks and embers, improving safety. When closed, glass doors can increase the firebox temperature, leading to more complete combustion and reduced emissions. However, it's important to select doors that are designed specifically for fireplaces and that provide adequate ventilation to prevent overheating and potential damage. Glass doors should be cleaned regularly to maintain optimal visibility and heat transfer.

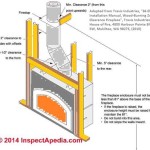

Damper upgrades are also crucial for minimizing heat loss. Traditional throat dampers, located at the base of the chimney, are often ineffective at creating a tight seal. Replacing a throat damper with a top-sealing damper can significantly reduce air leakage when the fireplace is not in use. Top-sealing dampers are installed at the top of the chimney and feature a rubber gasket that creates an airtight seal, preventing warm air from escaping and cold air from entering. These dampers also help to keep out rain, snow, and debris, protecting the chimney from damage and preventing water leaks.

Finally, consider installing a heat exchanger. These devices are designed to capture heat that would otherwise escape up the chimney and redirect it back into the room. Heat exchangers typically consist of a series of metal tubes or fins that are positioned within the chimney flue. As hot gases pass through the exchanger, they transfer heat to the metal, which then radiates the heat into the room. While heat exchangers can provide a noticeable improvement in heat output, they can also increase the risk of creosote buildup, so regular chimney inspections and cleaning are essential.

Optimizing Fuel Selection and Preparation

The type and quality of wood used in a fireplace significantly impact its efficiency and heat output. Using seasoned wood, properly stored and prepared, is crucial for maximizing combustion efficiency and minimizing emissions.

Seasoned wood refers to wood that has been allowed to dry for an extended period, typically six months to a year. Green wood, or freshly cut wood, contains a high moisture content, which reduces its heat output and increases smoke production. When green wood is burned, a significant amount of energy is expended to evaporate the water, leaving less energy available for heating. Furthermore, the high moisture content leads to incomplete combustion, resulting in the release of unburned gases and particulate matter. Seasoning wood allows the moisture content to decrease to around 20%, resulting in a hotter, cleaner, and more efficient burn.

Proper wood storage is essential for maintaining the dryness of seasoned wood. Wood should be stacked off the ground on pallets or racks to allow for air circulation. The stack should be covered with a tarp or shed roof to protect it from rain and snow, but the sides should be left open to allow for ventilation. Stacking wood in direct sunlight can also help to accelerate the drying process. Avoid storing wood directly against the house, as this can attract insects and moisture and potentially damage the siding.

Wood size and species also play a role in fireplace efficiency. Smaller pieces of wood tend to ignite more easily and burn more quickly, while larger pieces burn more slowly and provide a longer-lasting heat. The optimal size depends on the size of the fireplace and the desired burn time. Hardwoods, such as oak, maple, and ash, are denser than softwoods, such as pine and fir, and therefore contain more energy per volume. Hardwoods burn longer and produce more heat than softwoods. However, softwoods ignite more easily and can be useful for starting a fire.

Avoid burning treated wood, painted wood, or any other materials that may release harmful chemicals when burned. These materials can generate toxic fumes that are hazardous to human health and can also damage the fireplace and chimney.

Implementing Efficient Burning Practices

Even with design improvements and proper fuel selection, inefficient burning practices can negate many of the benefits. Employing specific techniques can significantly enhance heat output and reduce emissions, leading to a more efficient and environmentally responsible fire.

Establishing a hot fire quickly is crucial for achieving efficient combustion. Use kindling and small pieces of wood to start the fire and gradually add larger pieces as the fire builds. Avoid using excessive amounts of paper or flammable liquids, as these can create a smoky and potentially dangerous fire. Once the fire is established, maintain a steady flame and avoid smothering the fire with too much wood. A hot fire burns more completely and produces less smoke and creosote.

Air control is essential for regulating the burning rate and combustion efficiency. Most fireplaces are equipped with an air control damper that allows you to adjust the amount of air entering the firebox. Opening the damper increases the air supply, leading to a hotter and faster burn. Closing the damper reduces the air supply, leading to a slower and cooler burn. Experiment with different damper settings to find the optimal balance between heat output and burn time. Be careful not to close the damper too much, as this can lead to incomplete combustion and increased smoke production.

"Top-down" or "upside-down" fire building is more efficient. This technique involves placing the largest pieces of wood at the bottom of the firebox, followed by smaller pieces and kindling on top. The fire is then lit from the top, allowing the flames to gradually burn downwards. This method promotes more complete combustion and reduces smoke production because the hot gases and smoke pass through the flames, igniting any remaining combustibles. It also creates a more even and consistent burn, reducing the need for frequent adjustments.

Regular chimney inspections and cleaning are essential for maintaining fireplace efficiency and safety. Creosote, a byproduct of incomplete combustion, can accumulate in the chimney flue, reducing airflow and increasing the risk of chimney fires. The National Fire Protection Association (NFPA) recommends that chimneys be inspected at least once a year and cleaned as needed. Hire a qualified chimney sweep to inspect and clean your chimney to ensure that it is free of creosote and other obstructions. Regular chimney maintenance is crucial for preventing chimney fires and ensuring the safe and efficient operation of your wood-burning fireplace.

How Can I Make My Traditional Masonry Fireplace More Efficient

How To Make Your Fireplace More Efficient

3 Ways I Improved Wood Stove Heating

How To Make A Fireplace More Energy Efficient 4 Steps

Energy Efficient Wood Burning Fireplaces

Fireplace Inserts 5 Money Saving Benefits Efficient Heating

How Can I Turn My Fireplace Into A Super Efficient Heat Source

What Will Make Your Fireplace Energy Efficient Rockford Chimney

How To Improve Your Wood Stove S Efficiency

How To Make Your Fireplace More Energy Efficient Quadra Fire

Related Posts