How to Troubleshoot and Fix Common Gas Fireplace Issues

Gas fireplaces offer a convenient and efficient way to add warmth and ambiance to a home. However, like any mechanical appliance, they can experience problems that require troubleshooting and repair. This article provides a comprehensive guide to diagnosing and addressing common issues encountered with gas fireplaces. Safety is paramount when working with gas appliances. If unsure about performing any repair, a qualified and licensed technician should be consulted.

Key Point 1: Addressing Pilot Light Problems

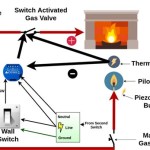

The pilot light is a small, continuous flame that ignites the main burner of a gas fireplace. Issues with the pilot light are among the most frequent problems encountered. Several factors can contribute to pilot light malfunction, including a dirty pilot assembly, a faulty thermocouple or thermopile, and a blocked pilot orifice. Furthermore, gas supply problems can also influence the normal function of the pilot light.

Cleaning the Pilot Assembly: Over time, dust, debris, and carbon deposits can accumulate on the pilot assembly, obstructing the gas flow and preventing the pilot light from staying lit. To clean the pilot assembly, first turn off the gas supply to the fireplace. This is typically accomplished by locating the gas shut-off valve near the fireplace and turning it to the "off" position. Next, allow the fireplace to cool completely. Remove the glass front panel of the fireplace, following the manufacturer's instructions. Using a small brush or vacuum cleaner with a brush attachment, carefully remove any visible debris from the pilot assembly. A specialized pilot orifice cleaning tool or a thin wire can be used to clear any blockages in the pilot orifice. Reassemble the pilot assembly and glass front panel.

Inspecting and Replacing the Thermocouple or Thermopile: The thermocouple or thermopile is a safety device that senses the presence of the pilot light flame. When the pilot light is lit, the thermocouple or thermopile generates a small electrical current that keeps the main gas valve open. If the thermocouple or thermopile fails, the main gas valve will close, extinguishing the pilot light. To test the thermocouple or thermopile, a multimeter is required. After turning off the gas supply and allowing the fireplace to cool, disconnect the thermocouple or thermopile from the gas valve. Connect the multimeter to the terminals of the thermocouple or thermopile. Light the pilot light and observe the multimeter reading. The reading should meet or exceed the manufacturer's specified voltage. If the voltage is low or zero, the thermocouple or thermopile needs to be replaced. Replacement involves carefully removing the old thermocouple or thermopile and installing a new one, ensuring proper connections to the gas valve.

Clearing a Blocked Pilot Orifice: The pilot orifice is a small opening that delivers gas to the pilot light. A blocked pilot orifice can restrict gas flow, causing the pilot light to be weak or nonexistent. To clear a blocked pilot orifice, turn off the gas supply to the fireplace and allow it to cool. Locate the pilot orifice, which is typically a small brass fitting near the pilot assembly. Use a specialized pilot orifice cleaning tool or a thin wire to carefully clear any blockages in the orifice. Avoid enlarging the orifice, as this can affect the gas flow and cause the pilot light to burn improperly. After clearing the blockage, reassemble the pilot assembly and glass front panel.

Checking the Gas Supply: Ensure that the gas supply valve is fully open and that there are no issues with the gas supply to the home. If other gas appliances in the home are not functioning properly, there may be a problem with the main gas supply line. In such cases, contact the local gas company for assistance.

Key Point 2: Addressing Issues with the Main Burner

The main burner is responsible for producing the primary source of heat in a gas fireplace. Problems with the main burner can result in weak flames, uneven burning, or a complete failure to ignite. Common causes of main burner issues include a dirty burner, a faulty gas valve, and a malfunctioning igniter or spark module.

Cleaning the Main Burner: Dust, debris, and carbon deposits can accumulate on the main burner, obstructing the gas flow and causing the flames to burn unevenly or weakly. To clean the main burner, turn off the gas supply to the fireplace and allow it to cool. Remove the glass front panel and carefully remove the burner from the fireplace. Using a soft brush or vacuum cleaner with a brush attachment, remove any visible debris from the burner. Inspect the burner ports, which are small holes or slots that allow gas to escape and ignite. Use a small wire or pin to clear any blockages in the burner ports. Reassemble the burner and glass front panel.

Inspecting and Replacing the Gas Valve: The gas valve controls the flow of gas to the main burner. If the gas valve is faulty, it may not allow enough gas to flow to the burner, resulting in weak flames or a failure to ignite. To test the gas valve, a qualified technician is recommended. Testing typically involves checking the voltage to the valve and measuring the gas pressure. If the gas valve is found to be faulty, it needs to be replaced. Replacement involves disconnecting the gas lines from the old valve and installing a new one, ensuring proper connections and gas-tight seals. This task requires specialized knowledge and tools and should be performed by a qualified technician.

Troubleshooting the Igniter or Spark Module: The igniter or spark module is responsible for igniting the gas at the main burner. If the igniter or spark module is not functioning properly, the main burner will not ignite. To troubleshoot the igniter or spark module, first ensure that the igniter wire is properly connected to the burner. Inspect the igniter tip for any cracks or damage. If the igniter is battery-operated, replace the battery. If the igniter still fails to produce a spark, it may need to be replaced. Replacement involves disconnecting the old igniter and installing a new one, ensuring proper connections.

Checking for Proper Ventilation: Adequate ventilation is crucial for the proper operation of a gas fireplace. Ensure that the fireplace vent is not blocked or obstructed. A blocked vent can prevent proper combustion and can lead to the buildup of dangerous carbon monoxide. Inspect the vent regularly for any signs of damage or blockage. If the vent is damaged, it needs to be repaired or replaced by a qualified technician.

Key Point 3: Addressing Issues with the Flame Appearance

The appearance of the flames in a gas fireplace can indicate underlying problems. Flames that are too high, too low, yellow, or sooty can be a sign of improper gas pressure, insufficient air supply, or a dirty burner. Addressing these issues can improve the fireplace's efficiency and safety.

Adjusting Gas Pressure: Improper gas pressure can affect the size and color of the flames. If the flames are too high, the gas pressure may be too high. If the flames are too low, the gas pressure may be too low. Adjusting the gas pressure requires specialized tools and knowledge and should be performed by a qualified technician. A manometer is used to measure the gas pressure, and the gas valve is adjusted accordingly to bring the pressure within the manufacturer's specified range.

Adjusting Air Supply: The air supply affects the combustion process and the color of the flames. Insufficient air supply can cause the flames to be yellow or sooty. To adjust the air supply, locate the air shutter or adjustment valve on the fireplace. Open the air shutter or valve to increase the air supply, and close it to decrease the air supply. Adjust the air supply until the flames are blue with slightly yellow tips. Avoid opening the air shutter too much, as this can cause the flames to be unstable or extinguish.

Cleaning the Glass Front Panel: A dirty glass front panel can obstruct the view of the flames and reduce the amount of heat that is radiated into the room. To clean the glass front panel, turn off the fireplace and allow it to cool. Remove the glass front panel and clean it with a glass cleaner specifically designed for fireplaces. Avoid using abrasive cleaners, as these can scratch the glass. Reassemble the glass front panel.

Checking for Gas Leaks: Gas leaks can be a serious safety hazard. If a gas leak is suspected, immediately turn off the gas supply to the fireplace and evacuate the area. Contact the local gas company or a qualified technician to inspect the fireplace for leaks. A gas leak detector can be used to locate the source of the leak. Never use an open flame to check for gas leaks. Gas leaks should be repaired immediately by a qualified technician.

Regular maintenance, including cleaning the burner and pilot assembly, can help prevent many of these issues. If persistent problems arise, seeking professional assistance is recommended to ensure safe and effective operation of the gas fireplace.

Reasons Your Gas Fireplace Isn T Working Experts

Gas Fireplace Keeps Shutting Off Here S What You Can Do

Gas Fireplace Troubleshooting Tips And Tricks

Gas Fireplace Won T Stay Lit Magic Touch Mechanical

Fireplace Won T Stay Lit This Is How You Fix It

Gas Fireplace Keeps Shutting Off Here S What You Can Do

Why Is It Important To Get My Gas Fireplace Logs Clean Regularly

How To Fix A Gas Fireplace That Keeps Turning Off Vertical Chimney Care

If Your Gas Fireplace Keeps Shutting Off Take These Steps

Why Your Gas Fireplace Won T Light And Potential Solutions

Related Posts