Understanding Wood Burning Fireplace Flue Pipe

A wood burning fireplace provides a source of supplemental heat and ambiance. However, its safe and efficient operation hinges on a critical component: the flue pipe. This pipe, also often referred to as a chimney connector pipe, serves to vent combustion byproducts, including smoke, gases, and particulate matter, out of the dwelling. A properly selected, installed, and maintained flue pipe is essential for preventing dangerous conditions such as carbon monoxide poisoning and chimney fires. This article will delve into the key aspects of wood burning fireplace flue pipes, encompassing material considerations, installation best practices, safety standards, and maintenance procedures.

Material Considerations for Flue Pipe Selection

The selection of appropriate flue pipe material is paramount. Improper material selection can lead to premature degradation, posing a significant safety risk. Several factors influence the choice of material, including the type of appliance being vented, the local climate, and prevailing building codes. Common materials used in flue pipe construction include:

- Single-Wall Steel Pipe: This is typically constructed from black or blued steel. It is the most economically viable option, but it is also the least insulated and thus radiates the most heat into the surrounding space. Single-wall pipe is generally used for connecting the appliance to the chimney or for installations where clearances to combustibles can be easily maintained. Building codes often restrict its use to certain applications where a masonry chimney is present.

- Double-Wall Stovepipe: Engineered with two layers of steel and an insulating air space between them, double-wall stovepipe reduces surface temperatures compared to single-wall pipe. This allows for closer clearances to combustible materials. It is often considered a safer and more versatile option than single-wall pipe. Double-wall pipe can be used where single-wall pipe is permissible and is frequently preferred for aesthetic reasons as well.

- Stainless Steel Pipe: Known for its corrosion resistance and durability, stainless steel is a premium material option. It can withstand the corrosive effects of flue gases, prolonging the lifespan of the flue pipe system. Stainless steel is frequently used in both single-wall and double-wall constructions. Its resistance to rust makes it suitable for installations where moisture may be a concern.

- Insulated Chimney Systems (Factory-Built Chimneys): These systems consist of multiple layers, including an inner liner, insulation, and an outer casing. They are designed to maintain high flue temperatures and minimize condensation, which can lead to creosote buildup. These systems are often required for installations where a masonry chimney is not present and offer superior safety and performance compared to traditional stovepipe. They meet stringent safety standards and are typically listed by nationally recognized testing laboratories.

The gauge of the steel used in the flue pipe is another crucial consideration. Thicker gauge steel provides greater structural integrity and heat resistance. Consult local building codes and manufacturer recommendations to determine the appropriate gauge for the specific application.

Installation Best Practices and Safety Standards

Proper installation of the flue pipe is critical to ensure safe and efficient operation of the wood burning fireplace. Failing to adhere to recommended installation procedures can result in fire hazards and carbon monoxide leaks. The following guidelines should be followed:

- Clearance to Combustibles: Maintaining adequate clearance between the flue pipe and combustible materials, such as walls, ceilings, and framing, is paramount. Building codes specify minimum clearance distances to reduce the risk of fire. These clearances vary based on the type of flue pipe used (single-wall, double-wall, or insulated). Failure to maintain the required clearances can result in the ignition of nearby combustible materials. Heat shields can be used to reduce clearances in certain situations, but they must be installed according to manufacturer instructions.

- Proper Pipe Connections: Securely connect sections of flue pipe using the appropriate fasteners, such as screws or clamps. All connections should be airtight to prevent flue gases from leaking into the living space. Examine all joints to ensure they are securely fastened and sealed. Loose connections can lead to carbon monoxide poisoning and reduced draft.

- Slope and Support: The flue pipe should be installed with a consistent upward slope of at least ¼ inch per foot towards the chimney. This slope facilitates the natural draft and allows for proper venting of flue gases. The flue pipe must be adequately supported to prevent sagging or collapse. Support straps or brackets should be installed at regular intervals, as specified by the manufacturer.

- Chimney Connection: The flue pipe should be connected to a properly sized and constructed chimney. The chimney should be inspected by a qualified professional to ensure it is free of obstructions and in good working condition. Improper chimney sizing or deterioration can impair the draft and increase the risk of chimney fires. If a masonry chimney is not present, a factory-built chimney system should be installed according to manufacturer instructions.

- Thimble Installation: Where the flue pipe passes through a wall, a proper thimble should be installed. A thimble is a fireproof sleeve that protects combustible wall materials from the heat of the flue pipe. Building codes typically require the use of a thimble when passing through combustible walls. The thimble should be installed according to the manufacturer's instructions and be securely fastened to the wall.

- Local Building Codes and Permits: Adherence to local building codes and obtaining necessary permits is essential. Building codes provide specific requirements for flue pipe installation, including material specifications, clearances, and inspection procedures. Obtaining the necessary permits ensures that the installation meets the required safety standards. Contact the local building department to determine the applicable codes and permit requirements.

It is highly recommended to have the flue pipe installation inspected by a qualified professional before using the fireplace. A professional inspection can identify potential safety issues and ensure that the installation complies with all applicable codes and standards.

Maintaining and Inspecting the Flue Pipe System

Regular maintenance and inspection of the flue pipe system are essential to ensure its continued safe and efficient operation. Creosote buildup, corrosion, and structural damage can compromise the integrity of the system and increase the risk of chimney fires and carbon monoxide leaks. The following steps should be taken to maintain and inspect the flue pipe system:

- Regular Cleaning: Creosote, a highly combustible byproduct of wood burning, can accumulate inside the flue pipe. Regular cleaning is necessary to remove creosote and prevent chimney fires. The frequency of cleaning depends on the type of wood burned, the burning habits, and the efficiency of the appliance. A general guideline is to have the flue pipe inspected and cleaned at least once per year, or more frequently if significant creosote buildup is observed. A professional chimney sweep can perform a thorough inspection and cleaning of the flue pipe and chimney.

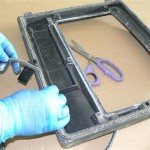

- Visual Inspection: Conduct regular visual inspections of the flue pipe for signs of corrosion, damage, or deterioration. Look for rust, cracks, dents, or loose connections. Pay particular attention to areas where the flue pipe connects to the appliance and the chimney. Any signs of damage should be addressed promptly.

- Creosote Inspection: Regularly inspect the flue pipe for creosote buildup. Creosote can be black or brown and can appear as flakes, tar, or a hardened glaze. The type and amount of creosote present can indicate the burning habits and the condition of the appliance. If significant creosote buildup is observed, schedule a professional cleaning.

- Damper Inspection: Inspect the damper to ensure that it opens and closes properly. A malfunctioning damper can impede the draft and allow flue gases to escape into the living space. Lubricate the damper mechanism if necessary.

- Professional Inspection: Have the entire flue pipe system inspected by a qualified professional at least once per year. A professional chimney sweep can identify potential problems that may not be apparent during a visual inspection. They can also provide recommendations for maintenance and repair.

- Record Keeping: Keep a record of all inspections, cleanings, and repairs performed on the flue pipe system. This record can be useful for tracking the condition of the system and identifying potential problems over time.

Ignoring maintenance and inspection can lead to serious safety consequences. A neglected flue pipe system is more likely to experience chimney fires, carbon monoxide leaks, and other hazards. A proactive approach to maintenance and inspection is essential to ensure the safe and efficient operation of the wood burning fireplace.

Choosing the right flue pipe and ensuring its proper installation and maintenance are crucial for the safety and efficiency of a wood-burning fireplace. By understanding the material options, adhering to installation best practices, and implementing a regular maintenance schedule, homeowners can minimize the risks associated with wood burning and enjoy the benefits of a safe and functional fireplace.

Twin Wall Chimney Flexible Flue Liner Stove Pipe

Twin Wall Flue System Explanation Examples And Diagrams

Flue Pipe Chimney Greenstone Soapstone Masonry Heaters

Flue Pipe Chimney Greenstone Soapstone Masonry Heaters

Wood Burner Flue Woodburner Flues

Twin Wall Chimney Flexible Flue Liner Stove Pipe

The Balanced Flue Everything You Need To Know Island Pellet Stoves

Enamel Vitreous Enamelled Connecting Flue Pipe

4 Decorative Flue Pipe Flare Collection

Remora Flue Pipe Fan For Vitreous Stovefitter S Warehouse