Marco Wood Burning Fireplace Parts: A Comprehensive Overview

Marco fireplaces are a well-established brand in the residential heating industry, known for their durability and efficiency in providing supplemental heat through wood burning. Understanding the various components of a Marco wood burning fireplace is essential for proper maintenance, troubleshooting, and eventual replacement of worn parts. This article provides a detailed look at the common parts found in Marco wood burning fireplaces, their function, and key considerations for sourcing replacements.

The construction of a Marco wood burning fireplace typically involves a firebox, chimney system, and aesthetic components that integrate the unit into the home's decor. Each of these areas contains specific parts designed to withstand high temperatures and facilitate efficient combustion. Regular inspection and timely replacement of these parts are crucial for maintaining the fireplace’s safety and optimal performance.

Understanding the Firebox Components

The firebox is the heart of the wood burning fireplace, where the combustion process takes place. It's designed to contain the fire and radiate heat into the room. Several key components make up the firebox, each with a specific role in the fireplace’s operation.

Firebrick: The firebox’s interior is typically lined with firebrick, a refractory material designed to withstand extreme temperatures without degrading. Firebrick absorbs and radiates heat, contributing to the efficiency of the fireplace. Over time, firebrick can crack or crumble due to thermal stress. Replacement is necessary when significant damage occurs, as it can affect the firebox’s structural integrity and reduce its insulation capabilities. Firebrick is available in various sizes and shapes, often requiring specific measurements to ensure a proper fit within the Marco fireplace model.

Grate: The grate is a metal framework that supports the wood within the firebox. It allows air to circulate underneath the wood, promoting more efficient combustion. Grates are typically made of cast iron or steel, materials chosen for their durability and ability to withstand high temperatures. Over time, the grate can warp or crack from repeated exposure to intense heat. A damaged grate should be replaced to ensure proper airflow and prevent wood from resting directly on the firebox floor, which can contribute to overheating and damage.

Andirons: While not strictly essential, andirons are often used in wood burning fireplaces to further elevate the wood and improve airflow. They also add a decorative element to the fireplace. Like grates, andirons are typically made of cast iron or steel and should be replaced if they become damaged or weakened.

Ash Dump Door and Frame: Located at the bottom of the firebox, the ash dump door allows ashes to be easily removed into a collection box or basement below. The door and frame need to be airtight to prevent air leakage into the firebox, which can affect the draft and combustion efficiency. The ash dump door and frame are exposed to corrosive ash and high temperatures, and can degrade over time, potentially leading to air leaks. Replacement may be necessary if the door no longer seals properly or if the frame is damaged.

Baffle: A baffle, often made of steel or ceramic, is located at the top of the firebox and designed to redirect the flow of hot gases. This increases the residence time of the gases in the firebox, allowing for more complete combustion and reducing creosote buildup in the chimney. A damaged or missing baffle can significantly reduce the fireplace’s efficiency and increase the risk of chimney fires. Replacement baffles are typically specific to the fireplace model and should be installed correctly to ensure proper operation.

Chimney System Components

The chimney system is vital for safely venting combustion gases and smoke out of the home. It consists of several components that work together to create a proper draft and prevent dangerous byproducts from entering the living space. The chimney system must be regularly inspected and maintained to ensure its proper function and safety.

Chimney Flue Liner: The flue liner is the inner lining of the chimney, designed to protect the chimney structure from the corrosive effects of combustion gases. It is typically made of clay tile, metal, or a poured-in-place concrete mixture. Over time, the flue liner can crack or deteriorate due to thermal stress and the corrosive nature of combustion byproducts. A damaged flue liner poses a significant safety risk, as it can allow gases to leak into the home or compromise the structural integrity of the chimney. Replacing a damaged flue liner is a critical safety measure. Options range from replacing individual clay tiles to installing a new stainless steel liner.

Chimney Cap: The chimney cap is a protective covering that sits atop the chimney. It prevents rain, snow, leaves, and animals from entering the chimney, which can obstruct the airflow and create a fire hazard. The chimney cap also often includes a spark arrestor, a mesh screen that prevents hot embers from escaping the chimney and potentially igniting nearby materials. A damaged or missing chimney cap should be replaced promptly to protect the chimney and prevent safety hazards.

Smoke Shelf: Located just above the damper, the smoke shelf is a horizontal surface designed to catch debris that falls down the chimney and to help equalize the pressure in the chimney, creating a more consistent draft. The smoke shelf should be cleaned regularly to remove accumulated debris and ensure proper airflow. Damage to the smoke shelf can affect the draft and increase the risk of smoke entering the home. While replacement of the smoke shelf is less common, it may be necessary in cases of significant damage or deterioration.

Damper: The damper is a movable plate located in the chimney that regulates the airflow. When open, it allows combustion gases to escape up the chimney. When closed, it prevents drafts from entering the home when the fireplace is not in use. A damaged or improperly functioning damper can significantly reduce the fireplace’s efficiency and increase energy costs. Common issues include warping, rusting, or a broken handle. Replacing a damaged damper can improve the fireplace’s performance and prevent energy loss. Options include throat dampers, which are located at the top of the firebox, and top-sealing dampers, which provide a more airtight seal at the top of the chimney.

Aesthetic and Functional Components

Beyond the core components of the firebox and chimney system, Marco fireplaces include various aesthetic and functional elements that contribute to the overall appearance and operation of the unit. These parts may not be directly involved in the combustion process but are essential for safety, convenience, and visual appeal.

Fireplace Doors: Fireplace doors provide a barrier between the fire and the room, preventing sparks and embers from escaping. They also help to regulate airflow and improve the fireplace’s efficiency. Fireplace doors are typically made of glass or metal and can be customized to match the home’s decor. Damaged or broken fireplace doors should be replaced to maintain safety and efficiency. Replacement options include various styles and materials to fit different Marco fireplace models.

Surround/Mantel: The surround and mantel are decorative elements that frame the fireplace opening and integrate it into the room’s design. They can be made of various materials, including wood, stone, brick, or metal. While primarily aesthetic, the surround and mantel also provide a safe buffer zone around the fireplace opening. Damage to the surround or mantel can detract from the fireplace’s appearance and potentially create a safety hazard. Replacement or repair may be necessary to maintain the fireplace’s visual appeal and safety.

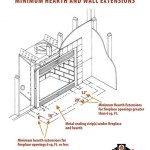

Facing Material: The facing material is the non-combustible material surrounding the firebox opening. It is crucial to protect nearby combustible materials, such as wall studs and flooring, from the intense heat radiating from the fireplace. Common facing materials include brick, stone, tile, and metal panels. Any damage to the facing material should be promptly repaired to maintain a safe distance between the firebox and combustible materials.

Air Intake Vents: Some Marco fireplaces feature air intake vents that draw air from outside the home to support combustion. This reduces the drain on the home’s heated air and improves the fireplace’s efficiency. The air intake vents should be kept clear of obstructions to ensure proper airflow. Damaged or blocked vents can negatively impact the fireplace’s performance and should be inspected and repaired as needed.

Proper maintenance of a Marco wood burning fireplace involves regular inspection of all these components. Identifying and addressing any issues promptly will extend the lifespan of the fireplace and ensure its safe and efficient operation. When sourcing replacement parts, it is essential to choose high-quality materials that are compatible with the specific Marco fireplace model. Consulting with a qualified fireplace professional can provide valuable guidance on selecting the right parts and ensuring proper installation.

5 Bar Grate For Model 36 Wood Burning Fireplace 87l26

Marco Builders Wood Burning Fireplace

A Plus Inc Lennox Superior Marco Majestic Peterson

Dual Fireplace Blower Marco

Pull Screen 36 In Set Of 2

Matte Black Marco C36cf C36hc C36hci Cm36hc Cm36hcd Fireplace Door

3 Bar Grate For 36 Model Wood Burning Fireplace Lb 98302c 87l29

Brushed Satin Nickel Marco Architect A46 Fireplace Door

A Plus Inc Lennox Hc 42 Replacement Parts And Accessories

Matte Black Marco C36cf C36hc C36hci Cm36hc Cm36hcd Fireplace Door