Understanding Wood Fireplace Insert Blower Motors

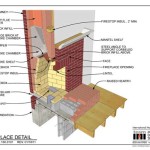

Wood fireplace inserts offer a more efficient and controllable heating solution compared to traditional open fireplaces. A crucial component of many wood fireplace inserts is the blower motor, responsible for circulating the heated air into the room. Understanding the function, maintenance, and potential issues related to the blower motor can optimize the performance and lifespan of your wood fireplace insert.

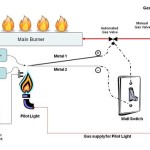

The primary function of a wood fireplace insert blower motor is to enhance heat distribution. Without a blower, heat generated by the fire tends to rise and concentrate near the ceiling. The blower draws cooler air from the lower part of the room, passes it over the heated firebox of the insert, and then forces the warmed air back into the room. This significantly improves the overall heating efficiency and comfort level within the space, allowing for more even temperature distribution and reducing wasted heat.

Importance of Proper Blower Motor Function

A properly functioning blower motor is essential for maximizing the heat output from a wood fireplace insert. A malfunctioning or inefficient blower can significantly reduce the amount of heat circulated into the room, negating the benefits of the insert itself. The blower's performance directly impacts the amount of wood required to maintain a desired temperature, potentially increasing fuel costs if the blower is not operating efficiently. Furthermore, a struggling blower motor may strain other components of the insert, potentially leading to more significant and costly repairs down the line. Addressing blower motor issues promptly ensures efficient heating, reduces energy consumption, and prolongs the lifespan of the fireplace insert.

Several factors can influence the performance and longevity of a wood fireplace insert blower motor. Dust and debris accumulation are common culprits, hindering the free movement of the blower fan and reducing its efficiency. This buildup can also cause the motor to overheat, potentially leading to premature failure. Regular cleaning and maintenance are therefore crucial for optimal performance. Voltage fluctuations and power surges can also damage the motor's internal components, emphasizing the importance of surge protection. Over time, the motor's bearings may wear down, resulting in increased noise levels and reduced airflow. Recognizing these potential issues and implementing preventative measures can significantly extend the lifespan of the blower motor.

Identifying a failing blower motor often involves recognizing changes in its typical operation. Reduced airflow is a common indicator, resulting in less noticeable heat being distributed into the room. Unusual noises, such as squealing, grinding, or rattling, can signal worn bearings or other mechanical problems within the motor. The blower motor may also operate intermittently or fail to start altogether. Overheating, accompanied by a burning smell, is a serious sign that the motor is straining and requires immediate attention. If any of these symptoms are observed, it's crucial to investigate the issue and address it promptly to prevent further damage to the blower motor and the overall fireplace insert system.

Maintaining Your Blower Motor for Longevity

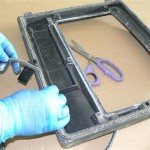

Regular maintenance is key to ensuring the long lifespan and optimal performance of a wood fireplace insert blower motor. The most crucial aspect of maintenance is regular cleaning. Disconnecting power to the insert before cleaning is paramount for safety. The blower assembly should be accessible after removing the insert's faceplate or accessing it from below, depending on the insert's design. Using a vacuum cleaner with a brush attachment, carefully remove dust and debris from the blower fan blades, motor housing, and surrounding areas. Compressed air can be used to dislodge stubborn particles, but it's essential to use caution and avoid directing the air stream directly into the motor's internal components. After cleaning, inspect the blower fan for any signs of damage or imbalance. If necessary, lubricate the motor's bearings according to the manufacturer's recommendations. Performing these maintenance tasks regularly, typically once or twice a year, can significantly extend the life of the blower motor.

If the blower motor fails completely, replacement is often the most practical solution. When selecting a replacement blower motor, it’s crucial to choose a model that is compatible with the specific wood fireplace insert. This typically involves matching the voltage, amperage, and physical dimensions of the original motor. The manufacturer's specifications or a qualified technician can provide guidance in selecting the correct replacement. Installing the new blower motor often involves disconnecting the old motor's wiring, removing it from the insert, and then connecting the new motor in its place. Always ensure that the power is disconnected before working on any electrical components. If unsure about the installation process, it's recommended to consult a qualified professional to prevent damage to the insert or electrical system.

Troubleshooting Common Blower Motor Issues

Addressing common blower motor issues often involves a systematic approach to identify the root cause of the problem. If the blower is not working, the first step is to check the power supply. Ensure that the insert is properly plugged in and that the circuit breaker has not tripped. If the power supply is confirmed, examine the blower motor's wiring for any loose connections or damage. A multimeter can be used to test the motor's continuity and voltage levels. If the wiring is intact and the motor is receiving power, the next step is to manually spin the blower fan. If the fan spins freely, the motor's starting capacitor may be faulty. If the fan is difficult to turn, the motor's bearings may be seized or the fan blades may be obstructed. These troubleshooting steps can help narrow down the problem and determine whether the blower motor needs to be repaired or replaced.

Addressing noise issues often involves identifying the source of the noise. Squealing noises typically indicate worn bearings, which may require lubrication or replacement. Rattling noises can be caused by loose screws or debris trapped within the blower assembly. Grinding noises can indicate a more serious problem with the motor's internal components. In some cases, tightening loose screws or removing debris can resolve the noise issue. However, if the noise persists, it may be necessary to consult a qualified technician to diagnose and repair the underlying problem. Ignoring unusual noises can lead to further damage and potentially require a more costly repair or replacement.

By understanding the function, maintenance requirements, and potential issues related to wood fireplace insert blower motors, homeowners can ensure optimal heating efficiency and prolong the lifespan of their fireplace inserts. Regular cleaning, prompt troubleshooting, and selecting compatible replacement parts are essential for maintaining a well-functioning and reliable heating system.

Pellethead Replacement Pacific Energy Wood Insert Convection Blower Distribution Room Air Fan Motor Only

Blower Motor 1m180

Noisy Gas Fireplace Blower Here S How To Replace It Diy

Blower Motor 1m180

Pacific Energy Wood Insert Convection Blower Perp 50246

Fireplace Insert Blower Motor Doityourself Com Community Forums

Osburn Matrix Wood Burning Insert Woodland Direct

Oa10505 130 Cfm Blower Fan

Which Is Better For Your Home Freestanding Stove Vs Fireplace Insert

10 Best Wood Stove Fans 2024 Forestry Reviews

Related Posts