Refacing a Fireplace with Stone: A Comprehensive Guide

Fireplaces serve as focal points in many homes, offering warmth and aesthetic appeal. Over time, however, the original facade of a fireplace may become dated, damaged, or simply no longer align with current design preferences. Refacing a fireplace with stone presents an opportunity to revitalize its appearance, adding texture, visual interest, and potentially increasing the home's value. This article provides a detailed overview of refacing a fireplace with stone, covering preparation, material selection, installation techniques, and considerations for safety and maintenance.

Planning and Preparation: Essential First Steps

Before embarking on a fireplace refacing project, meticulous planning is crucial. This stage involves assessing the existing fireplace structure, determining the desired aesthetic outcome, selecting appropriate stone materials, and accounting for necessary building codes and safety regulations. A poorly planned project can lead to structural issues, design flaws, and unnecessary expenses.

The initial step involves a thorough inspection of the existing fireplace. This includes examining the firebox for cracks or damage, assessing the structural integrity of the surrounding framework, and identifying any potential hazards such as asbestos or lead paint. If significant damage is discovered, it is advisable to consult with a qualified professional to ensure the fireplace is structurally sound before proceeding with the refacing process.

Next, consideration must be given to the desired finished look. Stone options range from natural stone veneers to manufactured stone products, each offering a unique aesthetic. Natural stone options include slate, limestone, granite, and fieldstone, each with its own distinct color variations, textures, and patterns. Manufactured stone, also known as cultured stone, is a concrete-based product designed to mimic the appearance of natural stone, offering a lighter weight and often a more consistent color palette. The choice of stone should complement the overall style of the room and the home's architecture.

Accurate measurements of the existing fireplace facade are essential for determining the quantity of stone required. It is advisable to purchase approximately 10-15% more stone than the calculated area to account for cuts, waste, and potential breakage. Additionally, consider the thickness of the stone and how it will integrate with adjacent surfaces such as the mantel or flooring. Any necessary adjustments to these surfaces should be planned in advance.

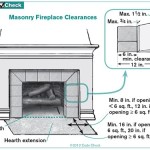

Finally, before beginning any work, it is crucial to consult with local building codes and obtain any required permits. Fireplace refacing projects may be subject to specific regulations concerning fire safety, structural integrity, and emissions. Failure to comply with these regulations can result in fines or the need to redo the work.

Material Selection: Natural vs. Manufactured Stone

The choice between natural and manufactured stone is a significant decision that impacts the aesthetic, cost, and installation process of the fireplace refacing project. Both options offer advantages and disadvantages, and the selection should be based on individual preferences, budget constraints, and project requirements.

Natural stone offers unparalleled beauty and authenticity. Each piece is unique, displaying natural variations in color, texture, and veining. This inherent variability contributes to a rich and organic aesthetic that is difficult to replicate with manufactured materials. Natural stone is also incredibly durable and long-lasting, capable of withstanding extreme temperatures and weathering. However, natural stone is generally more expensive than manufactured stone, and its weight can pose installation challenges. Cutting and shaping natural stone often requires specialized tools and expertise.

Manufactured stone, on the other hand, offers a more cost-effective and lightweight alternative. It is typically made from concrete that is molded and colored to resemble natural stone. Manufactured stone products are available in a wide range of styles and colors, providing greater design flexibility. The lighter weight of manufactured stone simplifies installation, reducing the need for extensive structural support. However, manufactured stone may not possess the same level of durability as natural stone, and its color may fade or wear over time. The overall aesthetic may also lack the unique character and depth of natural stone.

When selecting either natural or manufactured stone, it is essential to consider the specific environment of the fireplace. The stone should be heat-resistant and non-combustible, capable of withstanding the high temperatures generated by the fire. Additionally, the stone should be resistant to staining and easy to clean, as soot and ash can accumulate over time. Comparing samples of different stone types and finishes is crucial to making an informed decision that aligns with both aesthetic preferences and practical considerations.

Installation Techniques: Achieving a Professional Finish

The installation process for refacing a fireplace with stone requires patience, precision, and adherence to established techniques. Proper installation ensures a secure and aesthetically pleasing result. This process typically involves preparing the surface, applying mortar, setting the stone, and finishing the joints.

The first step is to prepare the existing fireplace surface. This involves removing any existing facing materials, such as brick, tile, or wood paneling. The underlying surface should be clean, dry, and structurally sound. If the surface is uneven or damaged, it may be necessary to apply a layer of concrete backer board to create a smooth and stable base for the stone. Backer board is typically attached to the existing surface using screws and construction adhesive. The installation of a metal lath over the backer board is recommended to provide a strong bonding surface for the mortar.

Mortar is the adhesive that binds the stone to the fireplace surface. It is crucial to use a high-quality, polymer-modified mortar specifically designed for stone veneer applications. This type of mortar offers superior adhesion, flexibility, and resistance to cracking. The mortar should be mixed according to the manufacturer's instructions, achieving a consistency similar to thick peanut butter. Avoid mixing excessive amounts of mortar at once, as it can dry out before it is used.

The process of setting the stone involves applying a thin layer of mortar to the back of each stone and pressing it firmly into place on the prepared surface. Begin at the bottom of the fireplace and work upwards, maintaining consistent spacing between each stone. Spacers can be used to ensure uniform joint widths. Irregularly shaped stones may require cutting to fit properly. A wet saw with a diamond blade is the recommended tool for cutting stone. Periodically check the level and plumb of the stone to ensure a straight and even installation.

Once the stone is set and the mortar has cured for at least 24 hours, the joints can be finished. This involves applying mortar to the joints using a grout bag or a pointing trowel. The mortar should be packed tightly into the joints, ensuring a complete fill. After the mortar has partially dried, the joints can be tooled to create a desired profile, such as a concave or a flat finish. Excess mortar should be wiped away with a damp sponge before it hardens completely. The entire installation should be allowed to cure for several days before exposing it to heat or moisture.

Sealing the stone surface after installation is highly recommended. A stone sealer helps to protect the stone from staining, water damage, and efflorescence (a white, powdery deposit). The sealer should be applied according to the manufacturer's instructions. Regular cleaning and maintenance will help to preserve the beauty and longevity of the stone fireplace facade.

Refacing Fireplace And Chimney Authority

Reface A Fireplace With The Look Of Stone Or Brick Barron Designs

15 Fabulous Fireplace Refacing Ideas Average But Inspired

Refacing Fireplace And Chimney Authority

Stone Fireplace Refacing Reface Brick Selex

Refacing A Fireplace With Stone Veneer Horizon

Fireplace Refacing So You Want To Bob Vila

Reface Your Fireplace Fresh New Look Hearth Remodeling

Refaced Fireplaces Charlotte Nc Santi Designs

Reface A Fireplace With The Look Of Stone Or Brick Barron Designs

Related Posts