Fake Stone For Fireplaces: Aesthetics, Installation, and Considerations

Fireplaces offer warmth and ambiance, often serving as a focal point in a living space. While traditional masonry fireplaces evoke a sense of permanence and classic charm, their construction can be costly, time-consuming, and structurally demanding. This has led to the increasing popularity of fake stone, also known as manufactured stone or stone veneer, as a viable and aesthetically pleasing alternative for fireplace surrounds and features.

Fake stone is a manufactured product designed to replicate the look and feel of natural stone. It’s composed of a lightweight concrete mix, often incorporating aggregates and pigments to achieve a wide range of colors, textures, and profiles, mimicking various natural stone types, such as fieldstone, river rock, stacked stone, and ledgestone. The versatility of fake stone allows homeowners to achieve the desired aesthetic without the weight and expense associated with natural stone.

The use of fake stone for fireplaces presents both advantages and disadvantages that warrant careful consideration before selection and installation. Understanding the properties, installation process, and limitations of fake stone is crucial for ensuring a safe, aesthetically pleasing, and long-lasting fireplace feature.

Aesthetic Versatility and Design Options

One of the primary benefits of fake stone is its aesthetic versatility. Manufacturers offer a vast array of styles, colors, and profiles, allowing homeowners to customize the look of their fireplace to complement their existing décor or achieve a specific design theme. Whether a rustic, modern, or traditional style is desired, there are fake stone options available to meet the requirements.

The color palette for fake stone is extensive, ranging from neutral grays and browns to vibrant reds, oranges, and even blues. The pigments are typically integrated throughout the material, ensuring that the color remains consistent even if the surface is scratched or chipped. This durability contributes to the long-term aesthetic appeal of the installation.

Texture is another key element of fake stone's aesthetic appeal. Manufacturers replicate the natural variations and imperfections found in real stone, creating a realistic and visually interesting surface. This textured surface also helps to conceal any minor imperfections in the underlying wall, contributing to a cleaner and more polished appearance.

The profile of the fake stone refers to its shape and size. Options range from thin veneers that create a sleek, modern look to thicker, more irregular stones that evoke a rustic, natural feel. Stacked stone profiles, in particular, are popular for creating dramatic fireplace surrounds, while ledgestone profiles lend themselves to a more refined and elegant aesthetic.

Furthermore, accessories such as hearth stones, mantels, and corner pieces are often available in matching or complementary styles, allowing for a cohesive and integrated design. These accessories enhance the overall aesthetic and contribute to a more finished and professional look.

Installation Process and Considerations

The installation of fake stone is generally less complex than that of natural stone, but it still requires careful planning and execution to ensure a safe and durable result. Proper surface preparation, adherence to manufacturer's instructions, and attention to detail are essential for a successful installation.

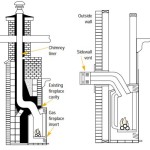

The first step in the installation process is to prepare the underlying wall surface. This typically involves cleaning the surface to remove any dirt, dust, or loose debris. Depending on the type of wall, a layer of metal lath may need to be installed to provide a suitable bonding surface for the mortar. The lath is typically attached to the wall studs with screws or nails, and it should be securely fastened to prevent movement.

Once the wall surface is prepared, a scratch coat of mortar is applied. This scratch coat provides a textured surface that allows the fake stone to adhere more effectively. The scratch coat should be allowed to dry and cure for the recommended time period before the stone is applied. This ensures that the mortar has sufficient strength to support the weight of the stone.

The fake stone is then applied to the scratch coat using a thin-set mortar. The mortar should be applied to the back of the stone and to the scratch coat, ensuring that there is good contact between the two surfaces. The stone should be pressed firmly into place and tapped lightly with a rubber mallet to ensure a secure bond.

Spacing between the stones is crucial for achieving the desired look. Some installations call for tight joints, while others feature wider, more rustic-looking joints. Spacers can be used to ensure consistent spacing between the stones. Once the mortar has dried, the joints are typically filled with grout or mortar to create a smooth and finished surface.

It’s imperative to adhere to local building codes and safety regulations during installation, especially concerning clearances from combustible materials. Consult with a qualified professional to ensure the fireplace meets all necessary safety standards.

For fireplaces specifically, heat resistance is a critical factor. While fake stone itself is generally non-combustible, the mortar used to adhere it to the wall must be heat-resistant and suitable for fireplace applications. Failure to use the appropriate mortar can result in cracking, crumbling, and even detachment of the stone over time.

Properties, Limitations, and Maintenance

While fake stone offers numerous advantages, it's important to understand its limitations compared to natural stone. Fake stone is typically lighter and easier to work with than natural stone, but it may not possess the same level of durability or longevity.

One of the primary differences between fake stone and natural stone is its composition. Natural stone is a naturally occurring material that has been formed over millions of years. It is typically denser and more resistant to weathering and erosion than fake stone. Fake stone, on the other hand, is a manufactured product that is susceptible to damage from moisture, UV exposure, and freeze-thaw cycles.

However, high-quality fake stone is designed to withstand the elements and provide years of reliable service. Many manufacturers offer warranties on their products to protect against defects and premature deterioration. It’s important to choose a reputable manufacturer and follow their installation guidelines to maximize the lifespan of the fake stone.

Maintenance of fake stone is relatively simple. Regular cleaning with a mild soap and water solution is typically sufficient to keep the surface looking its best. Avoid using harsh chemicals or abrasive cleaners, as these can damage the surface of the stone. Periodic sealing may also be necessary to protect the stone from moisture and staining.

One of the potential drawbacks of fake stone is its permeability. While it is generally water-resistant, it is not completely waterproof. Over time, moisture can penetrate the stone and cause it to deteriorate. This is particularly problematic in areas that are subject to frequent freezing and thawing. To mitigate this risk, it is important to properly seal the stone and ensure that the surrounding area is well-drained.

In terms of repair, fake stone can be more challenging to repair than natural stone. If a piece of fake stone is damaged, it may be difficult to match the color and texture of the existing stone. In some cases, it may be necessary to replace the entire section of stone to achieve a seamless repair. However, minor chips and cracks can often be repaired with patching compounds or mortar.

Ultimately, the decision of whether to use fake stone for a fireplace depends on individual preferences, budget constraints, and design goals. By carefully considering the aesthetic options, installation process, properties, and limitations of fake stone, homeowners can make an informed decision and achieve a visually appealing and long-lasting fireplace feature.

Choosing a qualified installer experienced with fake stone applications is critical. Incorrect installation can compromise the appearance, structural integrity, and safety of the fireplace surround. Reputable installers will be familiar with best practices and manufacturer recommendations, ensuring the project meets all code requirements.

Stone Fireplace Design And Remodel

Faux Stone Fireplace Entertainment Center Genstone

Faux Stone For Fireplaces

Faux Stone Electric Fireplace Rustic Ginny S

Stone Fireplace Makeover Part 2 Faux Whitewash Organized Ish

Stone Fireplace Design And Remodel

43 Top Fireplace Interior Design Stacked Stone Fireplaces Faux Veneer

ᑕ❶ᑐ Faux Stone Electric Fireplace Where Does It Match Best

Great Designs For Faux Stone Fireplaces And How To Diy

Cultured Stone Fireplaces The Stoners

Related Posts